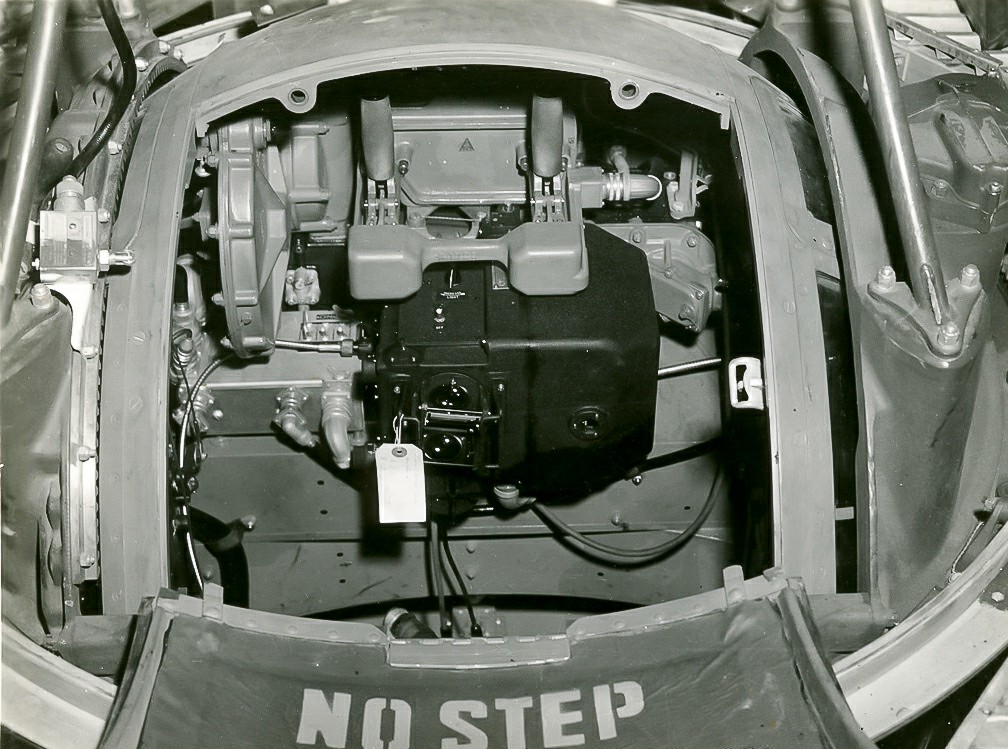

Some of you may recall that we were donated a K-4 back in August of 2023. While this sight was the correct early variant for 1943, this unit was sadly missing its side cover. We had hoped that another cover might come our away but this never materialized. When another early variant K-4 became available, we agonized over whether or not to spend the money, but we finally relented – after all, another may never come our way again. We were only able to make this purchase thanks to the contributions of our supporters. To all of you who have pledged on our behalf, we cannot thank you enough.

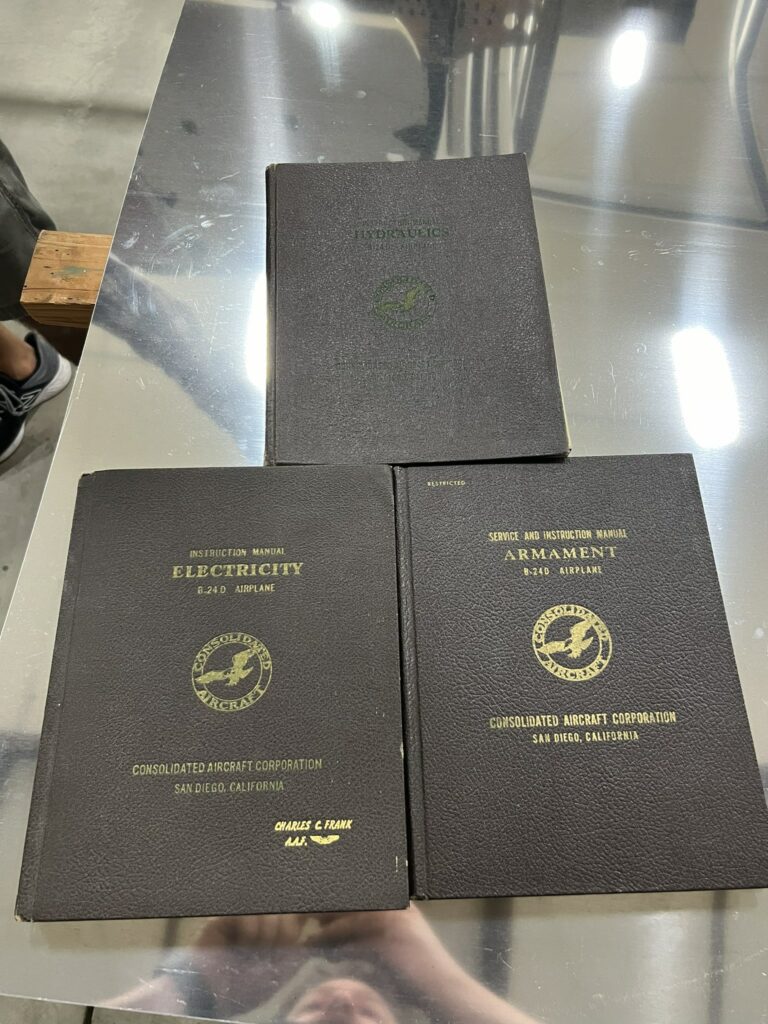

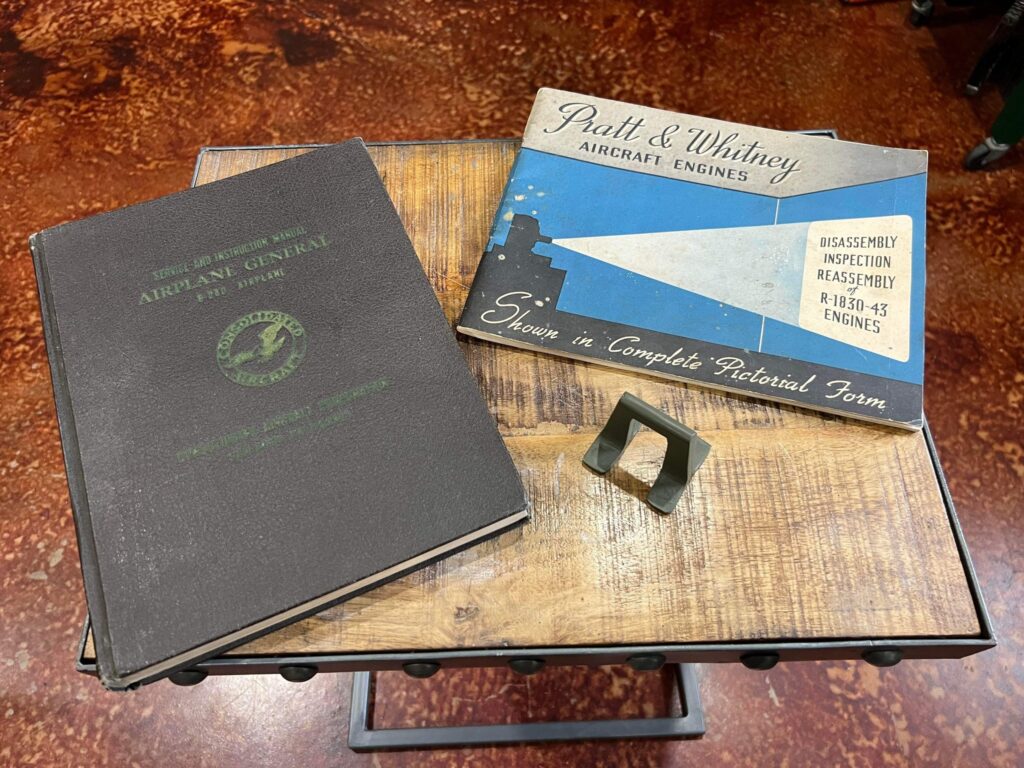

Longtime supporter David Webster, who lived nearby, offered to pick up the sight and bring it to us. He was also kind enough to not only purchase the donated sight for his collection, but he also donated hydraulic, electrical, and armament manuals for the Consolidated B-24 to the LB.30 restoration (which we are partnered with Project Warbird on). Thanks David!

Unlike the old gunsight, which was made under license by National Cash Register of Dayton, Ohio, this gunsight was manufactured by Sperry Gyroscope of Brooklyn, New York – the company who actually designed the sight. The sight is in very good shape and still retains the rubber weather seal on its side cover (a rather hard piece to find). That said, the sight will require some attention as several screws are missing, and the Polaroid adjustable shade is broken and will no longer adjust.

*Since this update, a working Polaroid adjustable shade has been acquired.

Another recent acquisition is a pair of Type G-11 Solenoids. These examples were NOS and only required cleaning to remove the 80 years’ worth of caked-on preservative. The solenoids were used to fire the Browning AN-M2 .50 caliber machine guns located in each of the B-17’s powered turrets. Pulling the trigger activated the solenoids, using a powerful electric magnet to fire the guns. Along with the unit donated by volunteer Howard Lawson (Virtual WWII B-17G Bomber Project) at the beginning of the year, we now have three firing solenoids. We need one more unit to have a complete set, though it would not hurt to have a spare or two in case one proves to be inoperable.

*We have since learned that there is a small, missing piece on all three solenoids, used to lock the pieces in place on the back of each gun.

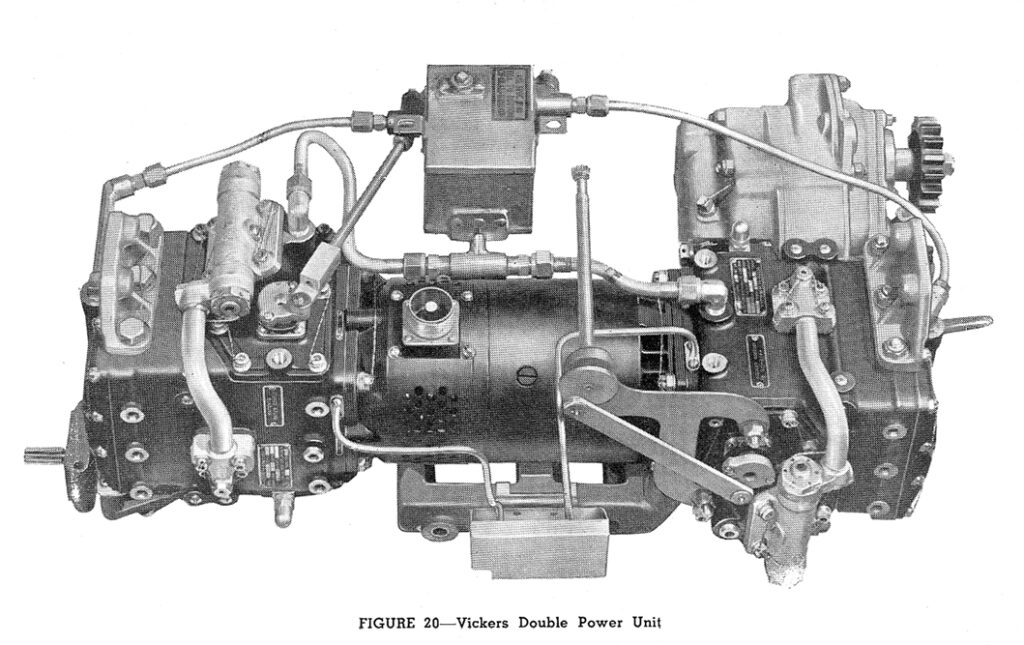

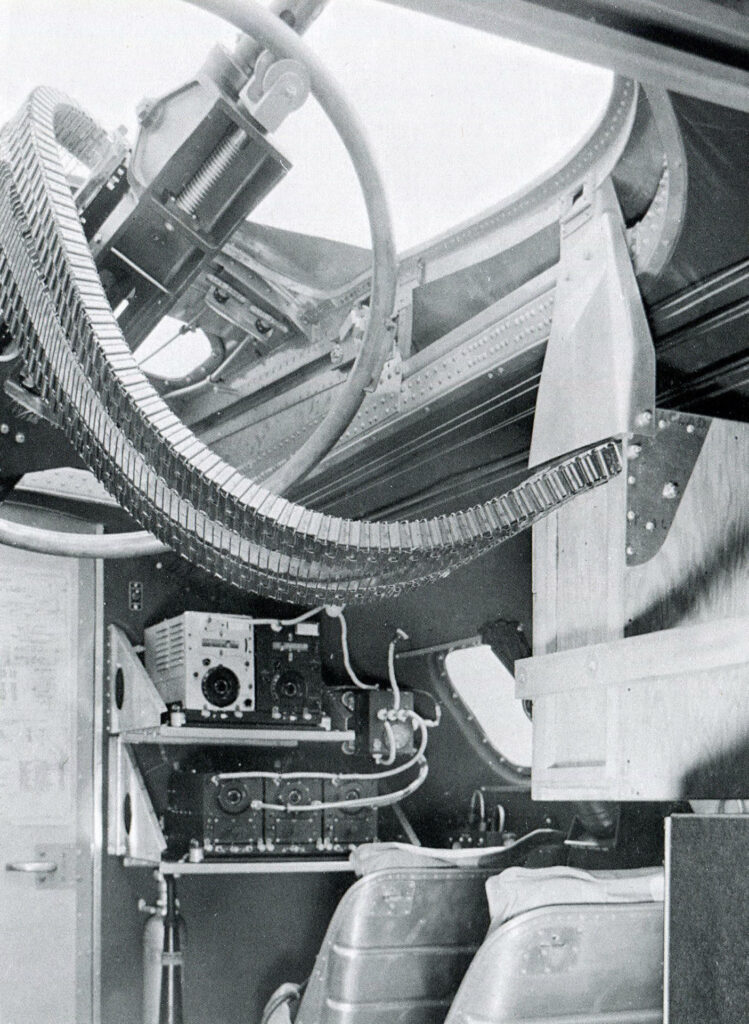

Another acquisition is the ball turret’s hydraulic reservoir tank. Now, I should stress here that the ball turret was NOT hydraulically powered. The turrets were powered by an electric motor, which turned a pair of hydraulic transmissions – one for azimuth and one for elevation. This tiny tank served as a reservoir for the hydraulic fluid feeding both tanks. This tank is surprisingly rough in construction, but it all appears to be original.

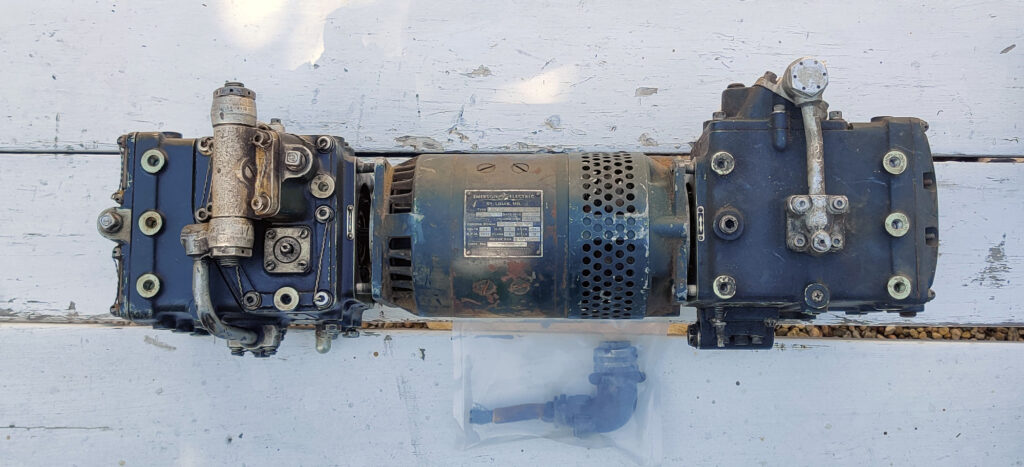

One aspect that our supporters may find interesting are the electric motors themselves. The motor going into the Type A-1 Upper Turret was built by Emerson Electric of St. Louis, Missouri. We felt this was appropriate since the top turret on Lucky Thirteen was, in fact, an Emerson. Since the A-2 Ball Turret was a Briggs, we have endeavored to avoid installing any Emerson components into the ball (the two companies famously did not get along). As such, the motor for the ball turret is a Diehl. Diehl was a division of Singer, famously based in New York, NY. For those not familiar with Singer, this means that the ball turret motor on Lucky Thirteen was quite literally made by a sewing machine company. Wild!

Also, I thought I might share a couple pictures showing progress related to the turrets. We have begun to disassemble the hand control, cleaning it inside and out and replacing the inaccurate green paint on the exterior. Inside we discovered that the rod for connecting the elevation control shaft is broken. It will have to be replaced. If anyone has a ball turret hand control or parts to one and would like to help by replacing this piece, please let us know!

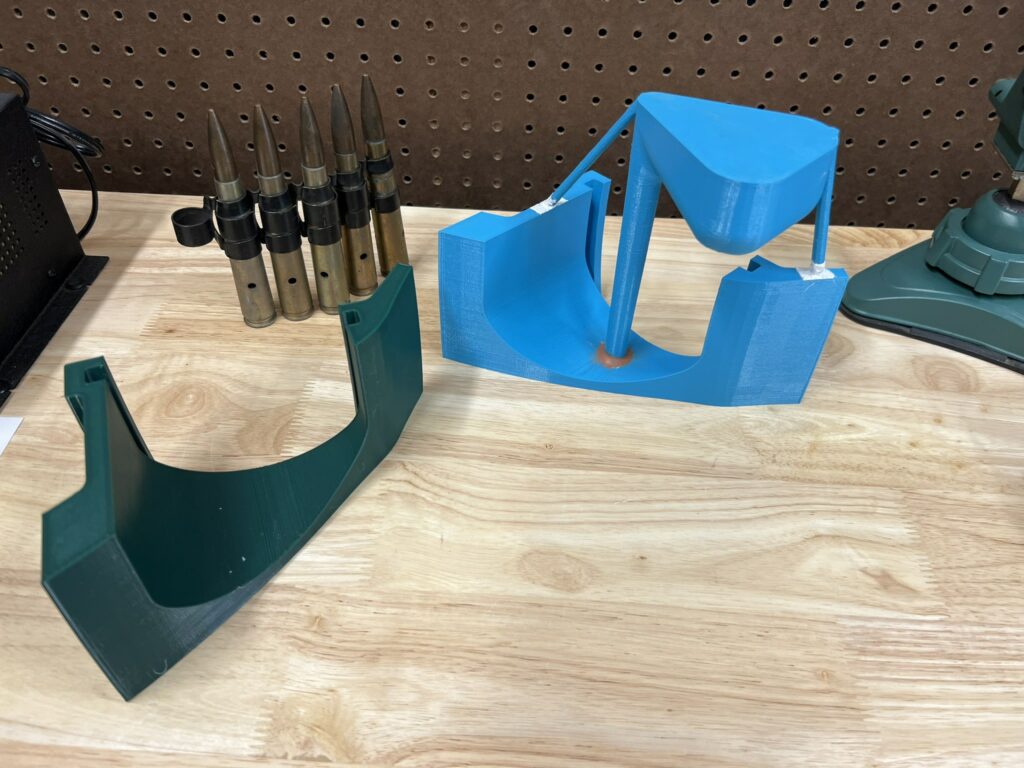

The other recent news involves the work to replace the broken section on the top turret dome. For those unaware, the dome was donated to the project by an amazing group of 384BG second-generation families, as Lucky Thirteen was, in fact, a member of the 384BG. The dome came to us with a portion under its left gun barrel missing, presumably being damaged over the past 80 years (maybe someone dropped it). Chris Erdahl of Asheville Product Development Solutions generously donated his time and experience to 3D scan the mirrored area, modeling the piece, and adjusting the model to create a plug for the opposite side.

Thanks to volunteer Bill Winter of Charlotte, North Carolina, this model is now in the hands of Clarke Easterling of Windy Hill Foundry of Morton, Mississippi. It is our hope that Windy Hill can cast a replacement for this broken piece, allowing us to weld it back into place and complete the restoration of this incredible dome assembly.

The newly-arrived Type K-4 Gunsight.

The gray piece at the top is the mounting bracket for holding the sight in place. We could not resist attaching it…

Photo taken 28 March 2024.

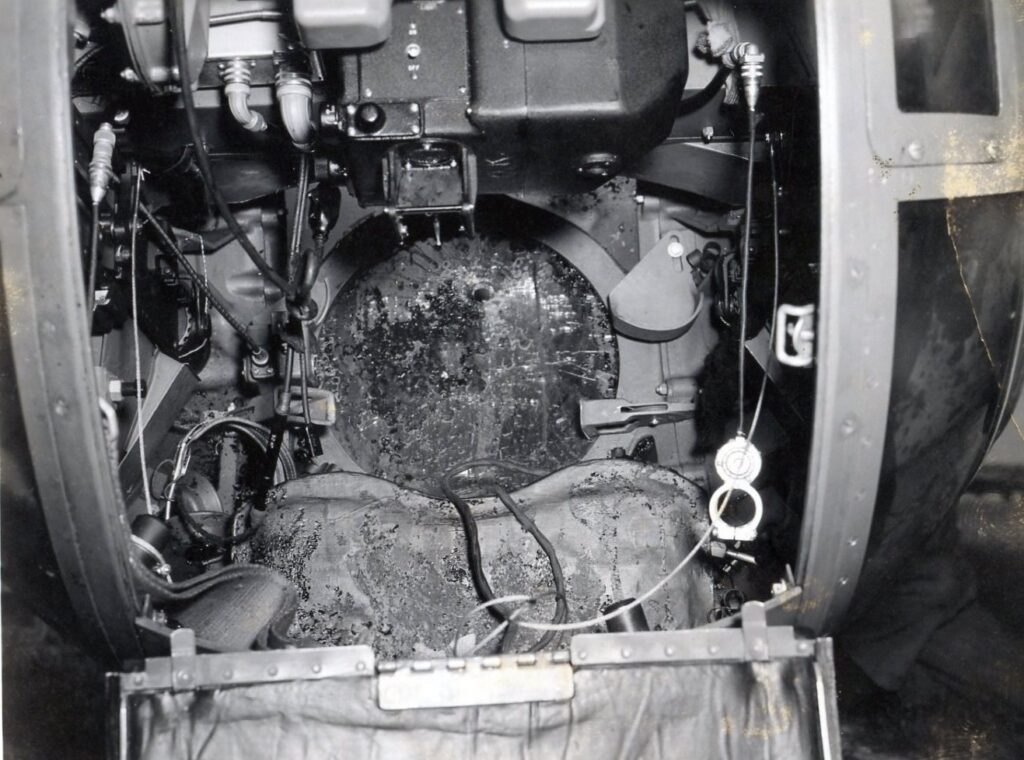

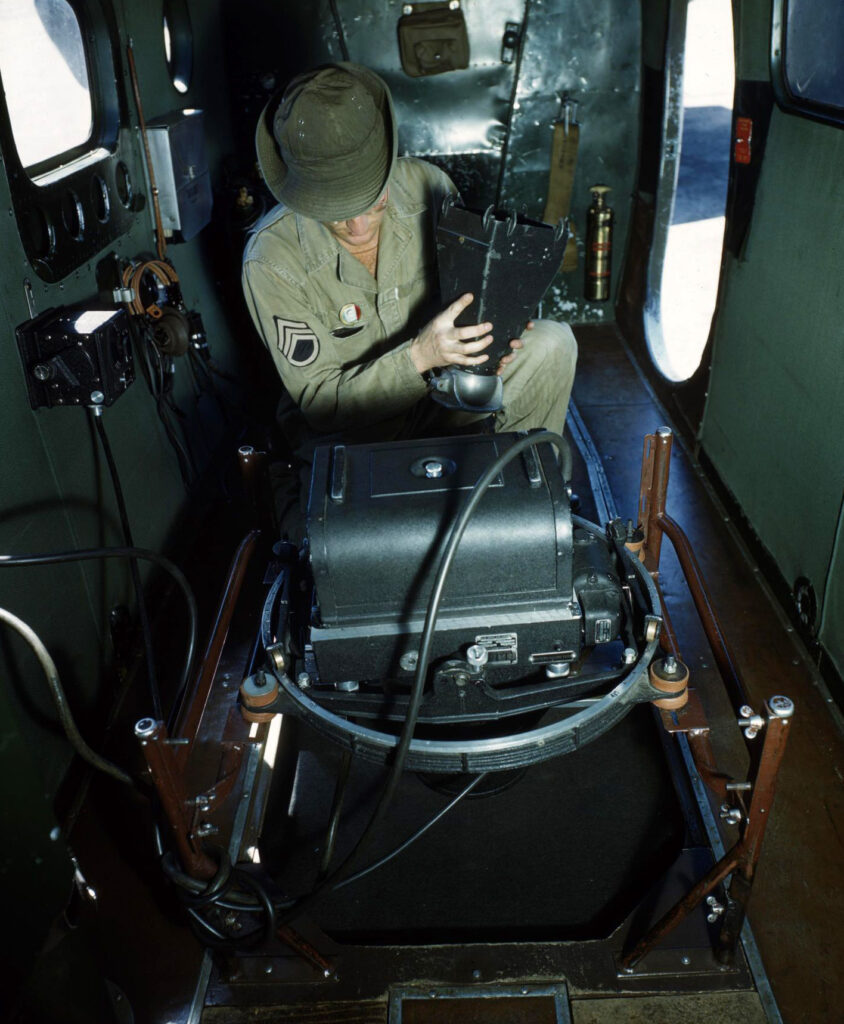

The interior of a Type A-2 Ball operated by TSGT Dick O. Gettys. The Type K-4 Gunsight is visible here.

Gettys received a Distinguished Service Cross for his actions on 4 July 1943, being severely wounded by a 20mm shell which exploded against his turret. Despite his injuries, he was nevertheless credited with an aerial victory that day.

TSGT Earl J. King of the 303BG, manning a Type A-2 Ball Turret. The turret’s Type K-4 gunsight is visible here.

The gunsight was an analog computer. Information on the turret’s elevation and azimuth, relative to the bomber, was fed into the gunsight via speedometer cables. The reticule on the lens was adjusted by a pedal adjusted by the gunner’s left foot. The target’s wingspan was manually input via a dial on the side of the gunsight (after all, aerial gunners were required to memorize the wingspan of enemy fighters). With these variables put together, the sight adjusted for lead, so the gunner did not have to.

Dan’s newly donated manuals for Consolidated LB.30 Maid of Athens.

Photo taken 27 March 2024.

The NOS Type G-11 Solenoids are fully cleaned from the 80 years’ of cake-on preservative.

Photo taken 13 March 2024.

Comparison photo showing a cleaned Type G-11 Solenoid and the other, as arrived.

Photo taken 12 March 2024.

A serviceman of the Royal Australian Air Force adjusts the Type G-11 Solenoid aboard a Type A-13 Ball Turret. The Type A-13 was the ball turret variant installed aboard Consolidated B-24D through Js.

This photo is somewhat unusual, as most of the B-24s which went to Australia were late-variants equipped with the Type A-13A ball turret. While there are many A-13A ball turrets surviving today, they were only used on late-B-24s and the short-lived B-32 Dominator.

The newly-acquired ball turret hydraulic reservoir tank. Note the rough seal-job, which appears to be factory original.

Photo taken 22 March 2024.

The electric motor assembly made by Diehl.

The heatshield was stripped prior to taking the picture. We are now working to get a color match of this green.

Photo taken 19 March 2024.

Holding the ball turret’s electric motor in place with one of its hydraulic transmissions. The transmissions below has not yet been cleaned.

Photo taken 19 March 2024.

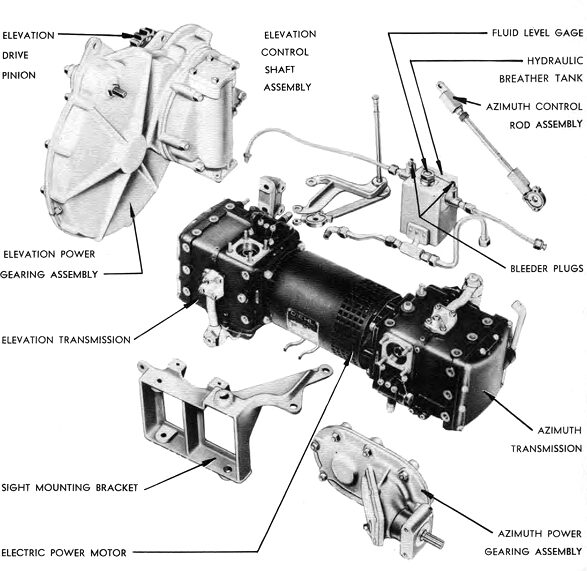

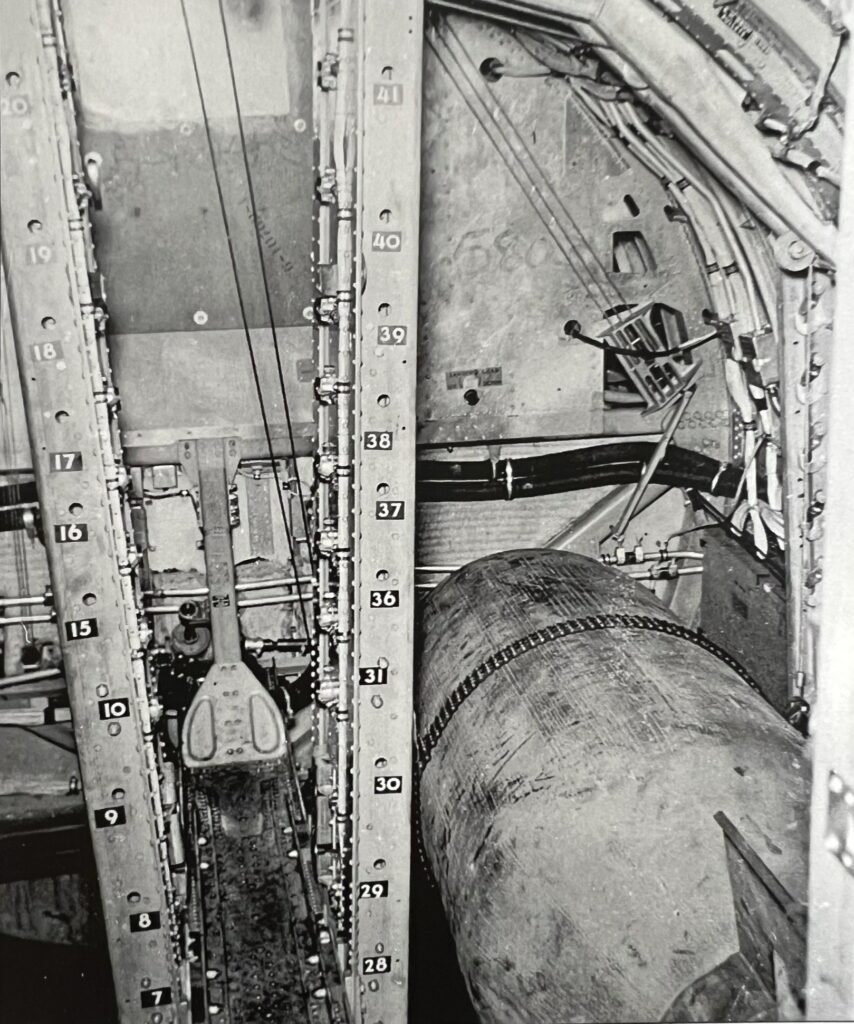

Manual illustration showing the layout of the ball turret’s motor assembly.

We have everything you see here except the small hydraulic dip pan at the bottom, the various tubes, one of the connector rods, and one of the attachment brackets. Thankfully, all of these are quite small.

Progress in disassembling and cleaning the ball turret’s hand control. The case assembly on the left has been stripped of the inaccurate green paint (visible right) someone sprayed on the control after the war. Briggs-made turrets had gray interiors and the original gray was visible in placed once we began disassembly.

Photo taken 26 March 2024.

The interior of a Briggs-built Ball Turret. Note the gray color and early-style hand control.

The side cover is removed from the newly arrived Type K-4 Gunsight for inspection.

Photo taken 28 March 2024.

The newly arrived Type K-4 Gunsight.

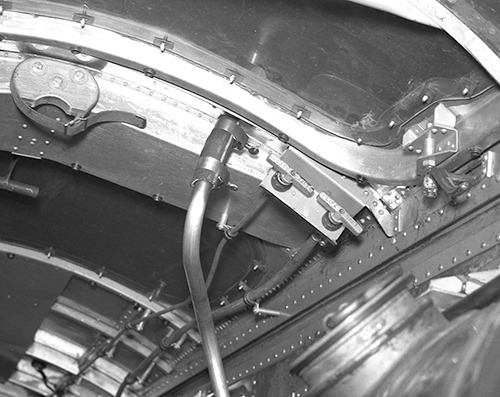

The sight’s bracket sits underneath the electric motor, with one side bolting to a hydraulic transmission.

The two holes on this side of the bracket are for mounting the hand control assembly.

Photo taken 28 March 2024.

The newly arrived Type K-4 Gunsight and its mounting bracket.

The bracket attaches to the sight via two rods. One rod, attached to the bracket, slides into a clip on the top of the gunsight. The other rod, attached to the gunsight, is pushed through a hold in the bracket assembly.

Photo taken 28 March 2024.

3D printouts of the plug assembly destined for the top turret dome on Lucky Thirteen.

Photo taken 19 March 2024.

An overhead view of the top turret dome for Lucky Thirteen.

The broken piece is visible on the right.

Photo taken 30 September 2021.

An early Type A-1 Upper Turret in service.

While the Type 1 and Type 2 dome are virtually indistinguishable, later domes were more varied. They were taller and usually featured bolted components for ease of access.

Carrying an Emerson turret, Lucky Thirteen had a Type 2 dome on her upper turret.

The 3D print of the top turret dome’s plug is dipped in ceramic slurry as part of the casting process. The plastic will later be heated and poured out, leaving behind a mold for the molten aluminum.

Photo taken 2 April 2024.

Several donations to share with everyone, so prepare for a long one:

First up are some pieces from long-time supporter Kenneth Wade in Muscle Shoals, Alabama.

Some of you might recall that Eric Miller (of Project Warbird) and I drove up to visit the New England Air Museum in Connecticut back in March 2023. We picked up several parts while up there, including an AN-M57 250 lb GP bomb.

To briefly recap the history –

One of the issues the US military faced in the Second World War was the differing procurement policies of the US Army and Navy. To combat this, the Roosevelt administration setup AN standards in an attempt to standardize parts for both services. For ordnance, this presented an interesting problem – while Army aircraft bombs had two lugs, like the British, Navy bombs only had one. As such, early-war bombs can be differentiated from late-war ones by the layout of the lugs. This AN-M57, for example, is a late-war bomb based on the fact that it had two lugs on one side and one lug on the other. I.e., it could be used by both the USAAF, USN, and RAF. This particular AN-M57 is dated 15 March 1945.

The single lug on the opposite side was broken and missing from this example and Kenneth volunteered to recreate it at his shop. It may not be necessary for mounting/displaying this piece, but we wanted the bomb to be accurate to its wartime condition. While Kenneth worked on the lug, I worked to remove the bomb’s outer corrosion and primed it with period-correct red oxide primer. Eric is currently reattaching the broken lug and applying the bomb’s final OD paint scheme. All that remains is to replace the missing tail fins and fuse plugs, reapply the original markings, and build a cradle for its final display. Along with the newly-fabricated lug, Kenneth also donated a pair of manuals to Project Warbird to go toward the restoration of Consolidated B-24/LB.30 Maid of Athens. Thanks Kenneth!

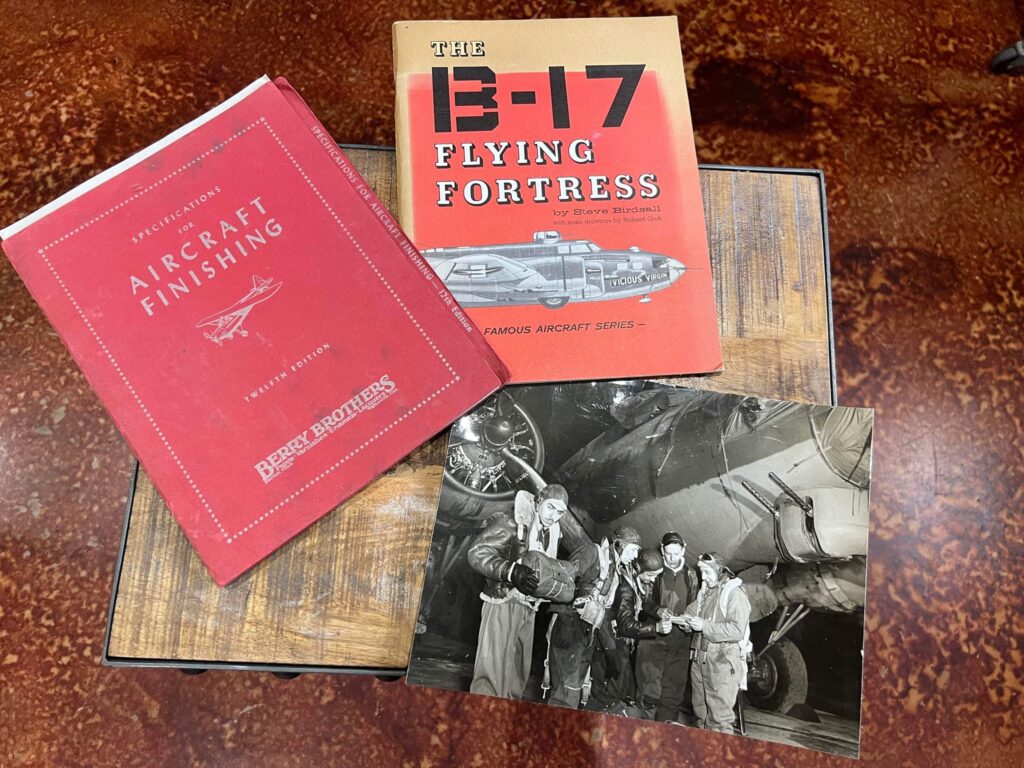

Another recent contribution of the published variety came from Mike Redpath of Washington, Oklahoma.

We were alerted to a listing on Facebook of someone selling an original Berry Bros. paint catalog. Mike won this listing and, understanding our interest, offered to donate an older example already in in his collection.

Berry Brothers Varnishes were the dominant name in aircraft paint during the golden age of aviation, and the B-17 was no exception. For example, we often note how wartime B-17s did not have painted interiors, the only area of the B-17’s interior being consistently painted being the cockpit. The color used here was produced by Berry Bros – Berryloid bronze green lacquer No. 234G9.

While Mike’s newly donated catalog does not contain a sample of Bronze Green, it does contain samples of several other wartime colors, including those used by the US military. We have taken the time to scan and upload this Berry Bros. publication and post it on our website. You can read it here.

Mike’s donation included a copy of the Famous Aircraft series entry on the B-17 by historian Steve Birdsall, and an original photo noted on the back as being the crew of Hitler’s Gremlin. We have yet to identify this aircraft’s serial number and unit. Thanks Mike!

Up next is an incredible donation from Tom Rajala of Houghton, Michigan –

Whenever I feel like the end is not in sight, Ray never fails to cheer me up, often reminding me that, if we just wait long enough, things tend to work out for us. This is a good example of that.

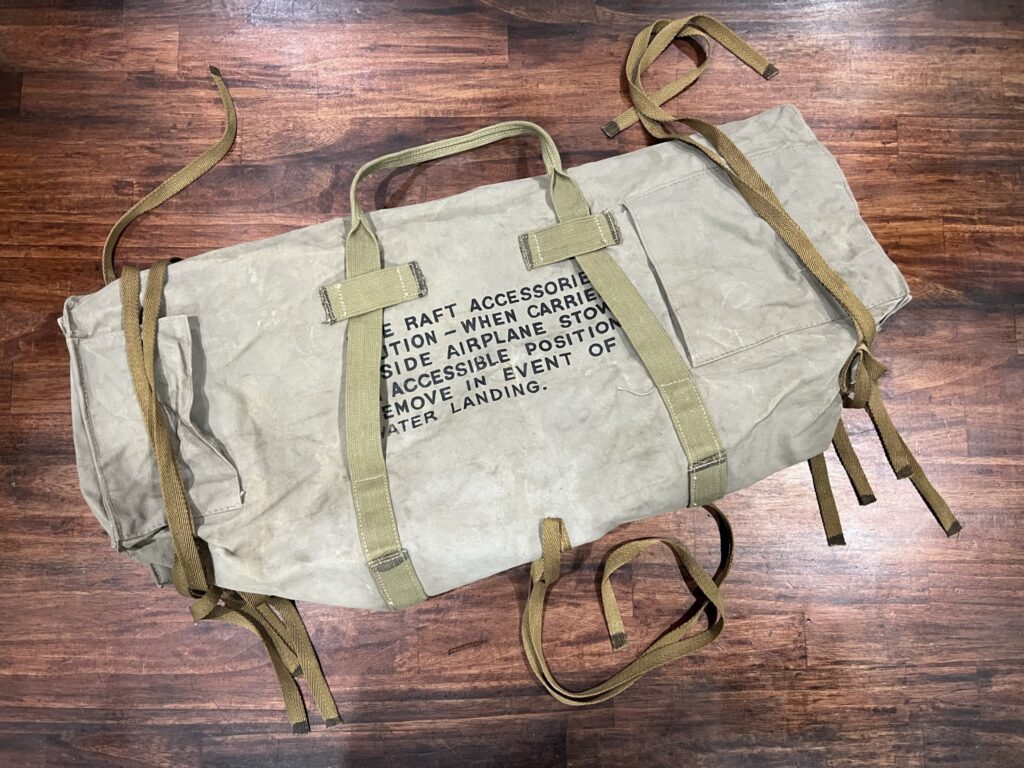

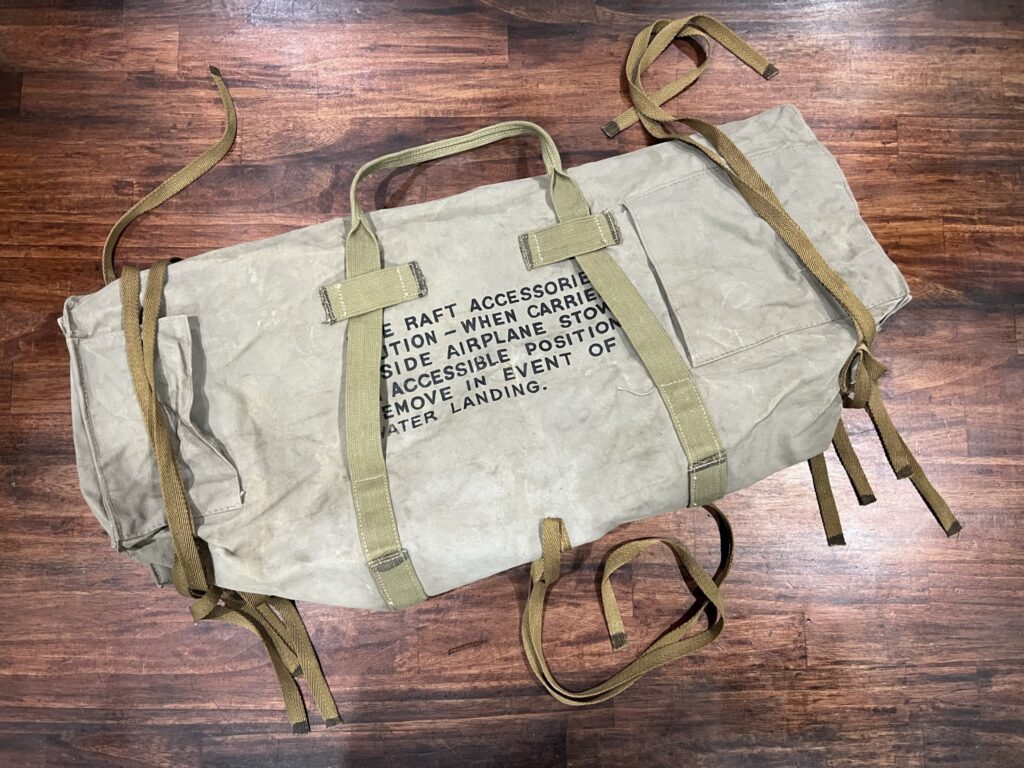

Back in December we purchased a Life Raft Accessory Bag for Lucky Thirteen (see below). The bag was kept in the cubby above the B-17F’s bomb bay, in between the bomber’s two life rafts. It was only after purchasing this bag that we learned that, to our dismay, the bag was incorrect. While the pattern was identical, the OD canvas was inaccurate to 1943 and what we needed was the older, yellow bag.

Out of the blue, a supporter notified us of a listing for the older type bag. Trying to conserve money, I reached out to the seller, and to our amazement, he offered to simply donate the bag. Incredible. Thanks Tom!

Speaking of life rafts, this brings me to the final contribution for this week –

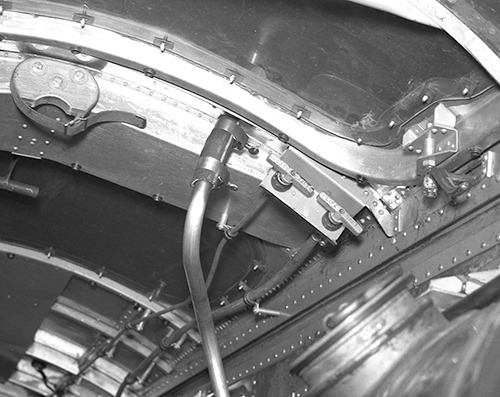

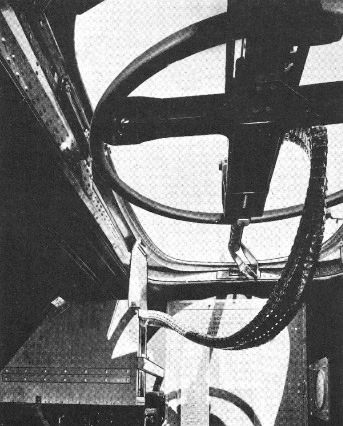

Our friends with the Boeing B-17E Desert Rat have long been needing replacement T-handles for the bomber’s life raft ejection system. The B-17’s life raft doors were located atop the bomb bay but opened by a pair of handles in the ceiling of the radio compartment. Pulling the handles opened the doors and automatically inflated the two life rafts.

In response, our friends at the Planes of Fame Air Museum loaned us the life raft ejection handle bracket from Piccadilly Lilly II (44-83684). The T-handles were CAD modeled by volunteer Howard Lawson (also of the Virtual WWII B-17G Bomber Project). The sockets for these handles presented a greater challenge and our friend Chris Erdahl of Asheville Product Development Solutions took up the case. Chris was kind enough to donate his time to CAD model and 3D print test pieces of the socket assembly to ensure a perfect recreation.

While we can have new T-handles 3D printed out of aluminum, the socket assemblies are delicate enough that they will require machining anew. In the meantime, Ray will recreate the mounting plate and we can return the reference bracket back to Planes of Fame. Thanks to Chris, Howard, and the team at Planes of Fame!

Kenneth’s newly-recreated bomb lug, along with donated copies of a the B-24D’s Service & Instruction Manual and the Disassembly, Inspection, and Reassembly Manual for R-1830-43 Engines.

Photo taken 20 February 2024.

Mike’s newly-donated Berry Bros. Specifications for Aircraft Finishing manual, B-17 history booklet by Steve Birdsall, and period photo noted as being of Hitler’s Gremlin.

Photo taken 20 February 2024.

Tom’s newly donated Life Raft Accessory Bag.

Photo taken 6 March 2024.

3D plastic printouts of the T-handle and socket assemblies sit beside the original Life Raft Release Bracket from Piccadilly Lilly II (44-83684).

Photo taken 20 March 2024.

The AN-M57 250lb GP bomb shortly after acquisition. Admittedly, it feels much heavier than that…

The loops were clamped on to help move it about, as was the piano moving cart.

Photo taken 3 April 2023.

The AN-M57 250 lb bomb is suspended in my old workshop for cleaning and priming before taking it to the hangar.

Photo taken 3 May 2023.

453BG armorers at the RAF Old Buckenham bomb dump. The bombs closest to the camera are AN-M64 500 pound GP bombs. To the far right are AN-M57 250 pound GP bombs. Note the large center lugs.

500 lb GP bombs – both in the early M43 and later M64 variants – were the bombs most commonly used by the US Army Air Forces over Europe.

Photo taken 17 February 1945.

Armorers load a Boeing B-17F with AN-M31 300 lb GP bombs.

Note that these older bombs lack the single lug on the opposite side.

Photo taken 18 December 1942.

The first coat of OD is applied to the AN-M57 250 lb bomb.

Photo taken 13 March 2024.

A piece of wreckage from My Buddy (42-31552, 457BG) showing the Berry Bros. bronze green color found in the B-17’s cockpit.

The previously acquired Life Raft Accessory Bag.

We were surprised to learn that it was not accurate to wartime aircraft. The tips of each strap are dipped in bee’s wax, which is typical of wartime practice.

Photo taken 1 December 2023

The wooden baffle is removed from this Boeing B-17’s life raft compartment to reveal the Life Raft Accessory Bag inside.

In black-and-white it is easy to confuse the older yellow bag with the later OD bag.

A Boeing B-17 flight crew undergoing a life boat drill. The baffle separating the life raft from its accessory bag can be seen in the stowage compartment here. Because this is a metal baffle, as opposed to a wooden one, it suggests that this is an older B-17.

Note the airman on the right – he is holding an older style, two-bag Gibson Girl emergency radio.

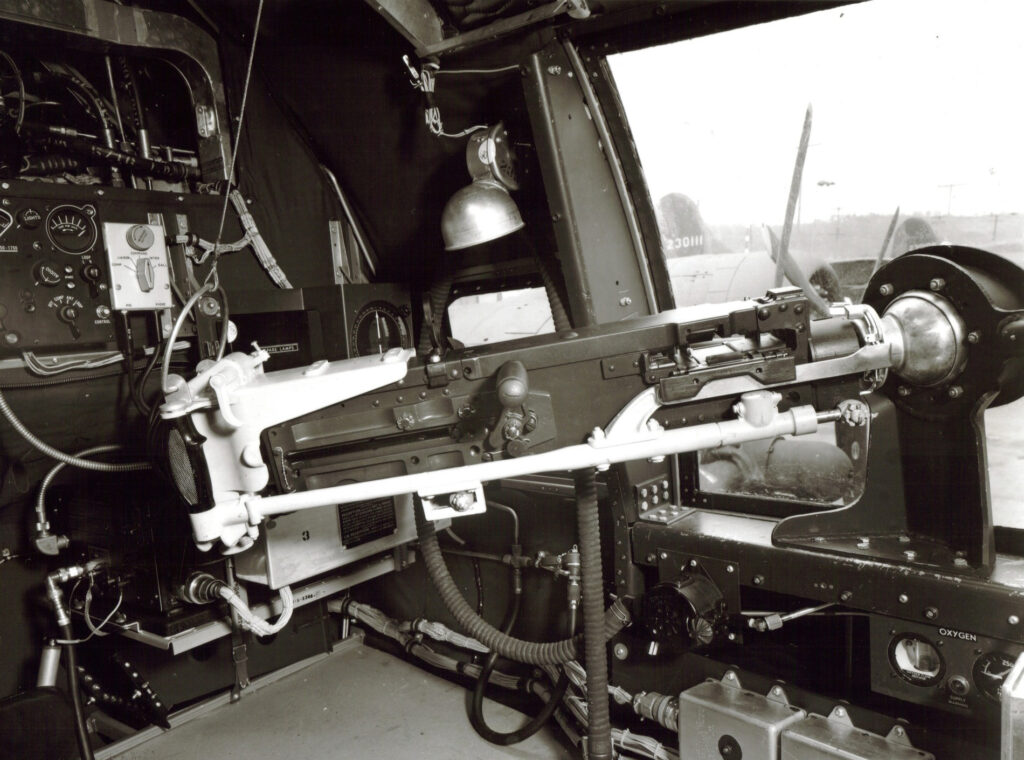

The T-handles which open the Boeing B-17’s life raft doors, visible here above the radio compartment.

Note the wooden piece at the upper left. This is used to tie down the radio hatch gun’s barrel when not in use.

Factory photo of the radio compartment aboard a Boeing B-17F. The life raft ejection assembly is visible on the ceiling behind the hatch gun.

Note the ammo chute for the hatch gun. We are in need of multiple left-hand facing (red band instead of green) Hughes ammo chutes for Lucky Thirteen. If anyone can help with this, please let us know!

3D plastic recreations of the life raft handle sockets are laid beside metal originals to ensure that they are perfect replicas.

Now to have them machined out of aluminum.

Photo taken 15 March 2024.

We now have a side-cap for the ball turret!

Some history:

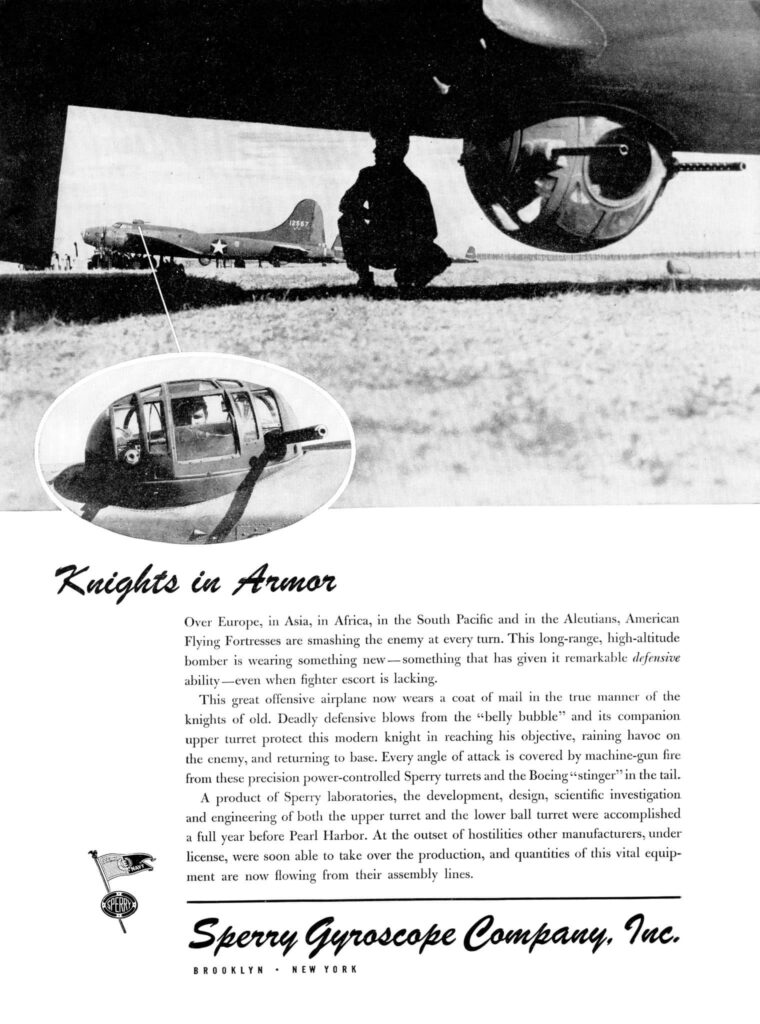

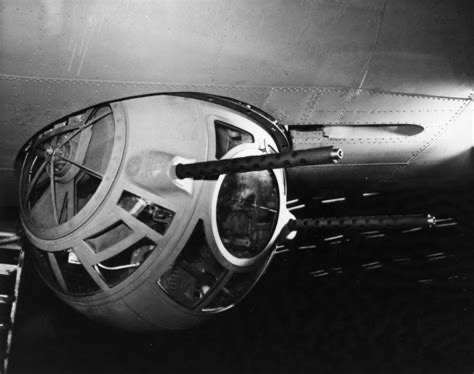

The Type A-2 Ball Turret was designed by Sperry Gyroscope to provide US heavy bombers with an effective means of ventral defense. The older remote systems, while smaller and lighter, were clumsy to handle and tended to cause vertigo to the operator. Sperry did not have the capability to manufacture ball turrets in-house, so the turret was licensed to Briggs Manufacturing (an autobody company) of Detroit, Michigan. Briggs was later joined by Emerson Electric of St. Louis, Missouri.

Ball turrets from these companies can largely be differentiated by the interior paint scheme – gray for Briggs and green for Emerson. Because the two companies had a poor working relationship, most ball turrets were Briggs types. The ball turret on Lucky Thirteen was a Briggs.

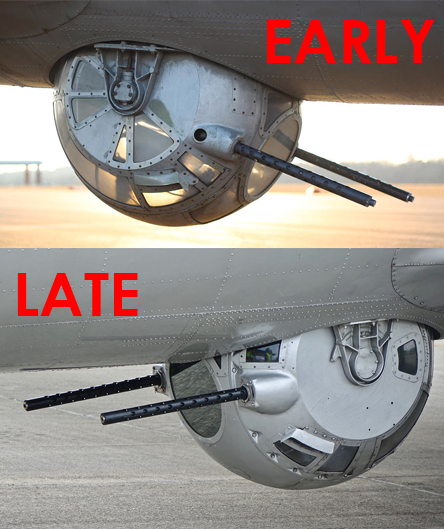

The A-2 series entered service with B-17E 42-2505 and was replaced by the A-2A model in B-17G Block-20-BO (roughly November 1943). Aside from the hanger assembly in the airplane, the easiest way to differentiate an A-2 from an A-2A are the side-caps – the A-2 had them, the A-2A did not. These side-caps were used to streamline the flow of air around the turret, and it was not uncommon for ground crews to remove them entirely to ease maintenance.

The B-24’s ball turret, known as the Type A-13, was not introduced until B-24D Block-140-CO, late in 1943. 967 Type A-13 turrets were fitted with side-caps before transitioning to the A-2A style ball.

While we technically need a pair, we have struggled to find even one of these caps for years. And we weren’t alone. The National Museum of the US Air Force, for example, was only able to find a single example for Memphis Belle, having to recreate the cap for the opposite side. As far as we know, the other surviving E and F model B-17s lack side-caps entirely. For a couple years we tried to acquire a set from someone we learned had some unissued, but he avoided directly answering our inquires for nearly two years. Surprisingly, there are two B-17Gs which have side-caps on their ball turrets, even though they are incorrect for their serials. These are Sleepy Time Gal (44-83624) on display at the Air Mobility Command Museum in Dover, Delaware and Shady Lady of the Collings Foundation, currently in New Smyrna Beach, Florida.

This should not be surprising. Most surviving ball turrets are Frankenstein amalgamations, the idea being that ANY ball turret is better than no ball turret at all. As such, our desire to be as accurate as possible only makes our task that more difficult.

And the cost of such pieces certainly does not help. For example, an early ball turret hanger and trunnion assembly was offered to us for some 20,000 USD – a number we have not come close to reaching so far. [This piece has since been acquired] The ball itself is another matter. While there are a few unused early balls out there – both domestically and overseas – their owners are loathe to part with them. We are currently reverse engineering a 3D scan of one (a very slow process) with the understanding that it may be necessary to cast one anew.

This side-cap was no easy feat, as it came here all the way from Australia – and we are EXTREMELY thankful that its owner reached out to us. Shipping from that part of the world is, by itself, never forgiving. Because of this, I must acknowledge that the purchase of this side-cap would not have been possible without the donations generally given by our supporters. Make no mistake, without you, this would have been impossible. A very special thank you from the bottom of our hearts. I hope that our work makes you proud.

So, where to from here?

Well, while we have side-cap, we still need one for the other side. Assuming another original never pops up, having this one in-hand means that we can reverse engineer it to create a replica.

In the meantime, while we have not yet raised the giant sums necessary to purchase ball turret body components, we have made excellent progress in gathering internal components. Hopefully we can have the ball turret’s motor assembly up and running this year so that, when we finally have a ball, it can be inserted to make it live right away.

The newly-arrived Type A-2 Ball Turret Side-Cap.

The part number confirms that this is side-cap is off of a Briggs-made turret.

Photo taken 2 March 2024.

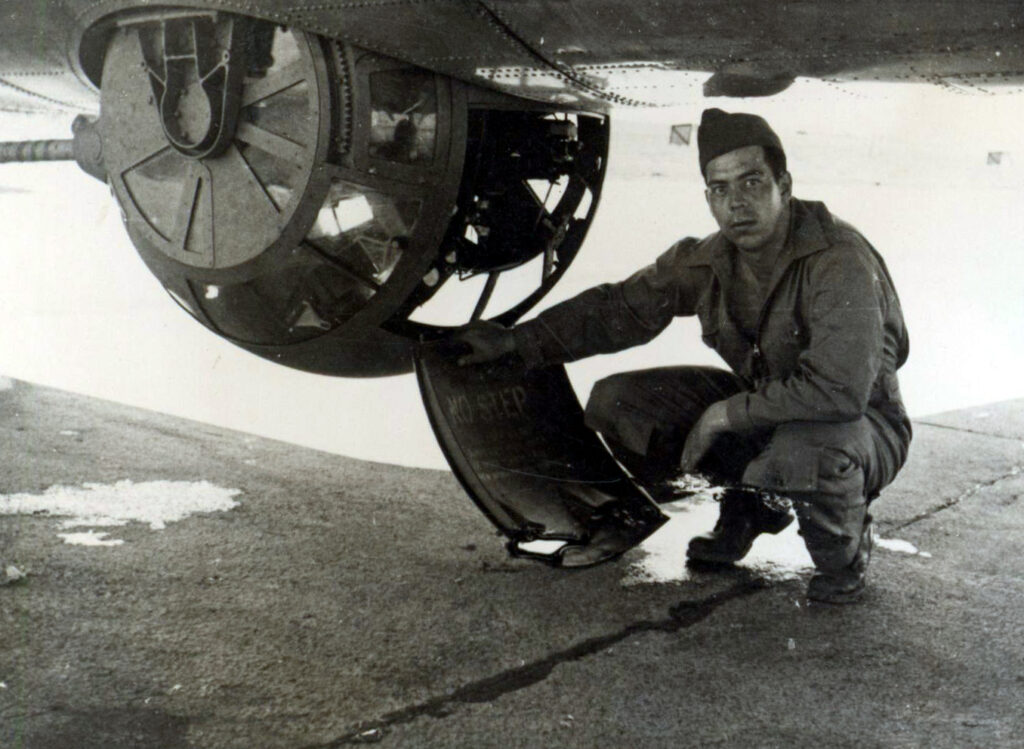

TSGT Dick O. Gettys preps the Type A-2 Ball Turret aboard Ruthie (42-5916, 92BG). The words “Ball of Fire” are painted on his turret’s side-caps.

Gettys received a Distinguished Service Cross for his actions on 4 July 1943, being severely wounded by a 20mm shell which exploded against his turret. Despite his injuries, he was nevertheless credited with an aerial victory that day.

TSGT Everett A. Dasher (303BG) poses with a Type A-2 Ball Turret while on a War Bond tour of the United States.

On 19 May 1943, a round from a Ju-88 deflected off of Asher’s parachute buckle and lodged itself into his spine. Asher lived with this hunk of metal for the rest of his life, passing away at age 85 in 2004.

The inside of the newly-arrived Type A-2 Ball Turret Side-Cap.

Photo taken 2 March 2024.

An advertisement from Sperry Gyroscope showcasing their Type A-1 Upper and Type A-2 Lower turret designs.

The powered turrets installed aboard Lucky Thirteen were identical to those shown here

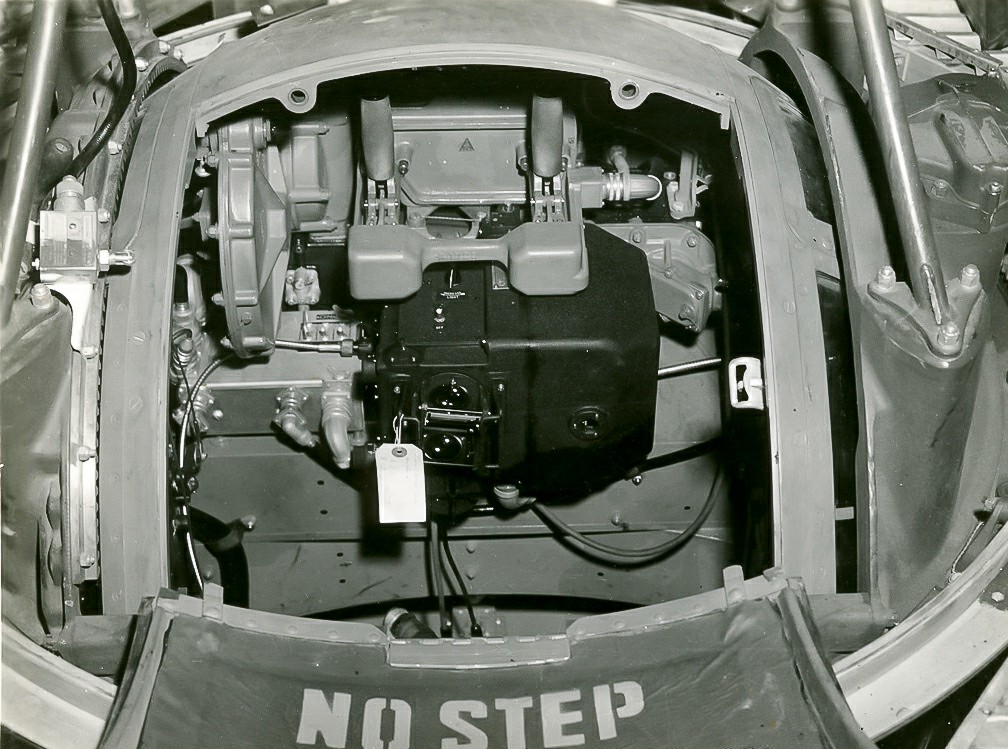

An early Type A-13 Ball Turret installed aboard a Consolidated B-24D.

The fact that this is a B-24 can be ascertained from the recesses in the fuselage for the turret’s gun barrels. Because the B-24 sat so low to the ground, its ball turret had to be retractable. B-24 crews often retracted their ball turrets for long periods in flight to improve aircraft performance.

SSGT Alan E. Magee, ball turret gunner on Snap! Crackle! Pop! (41-24620, 303BG). The side-caps have been removed form Magee’s turret. However, you can tell that this is an A-1 as the pieces for attaching the side-cap are still present.

Magee survived a fall of some 21,000 ft without a parachute on 4 January 1943, crashing through the glass of the St. Nazaire railway station. Magee had neglected to secure his safety strap, an uncomfortable belt which fit behind the gunner just in case the door wasn’t fully secured. While seriously injured, Magee received medical attention and made a slow recovery, resulting in Magee holding the record for the highest survived freefall until 1972.

SSGT George W. Youngs poses with the Type A-2A Ball Turret on Sitting Pretty (44-6170, 96BG). Note the flat portions of the trunnion support brackets – these are what indicates that this is an A-2A.

Sitting Pretty was lost with another crew over Berlin on 3 February 1944.

Many of today’s surviving ball turrets are Type A-13As, which were designed for late-B-24s and the Consolidated B-32. No A-13A was ever installed aboard a Boeing B-17 during the war.

These late ball turrets can be distinguished from the older models by the drastic alteration in window arrangement.

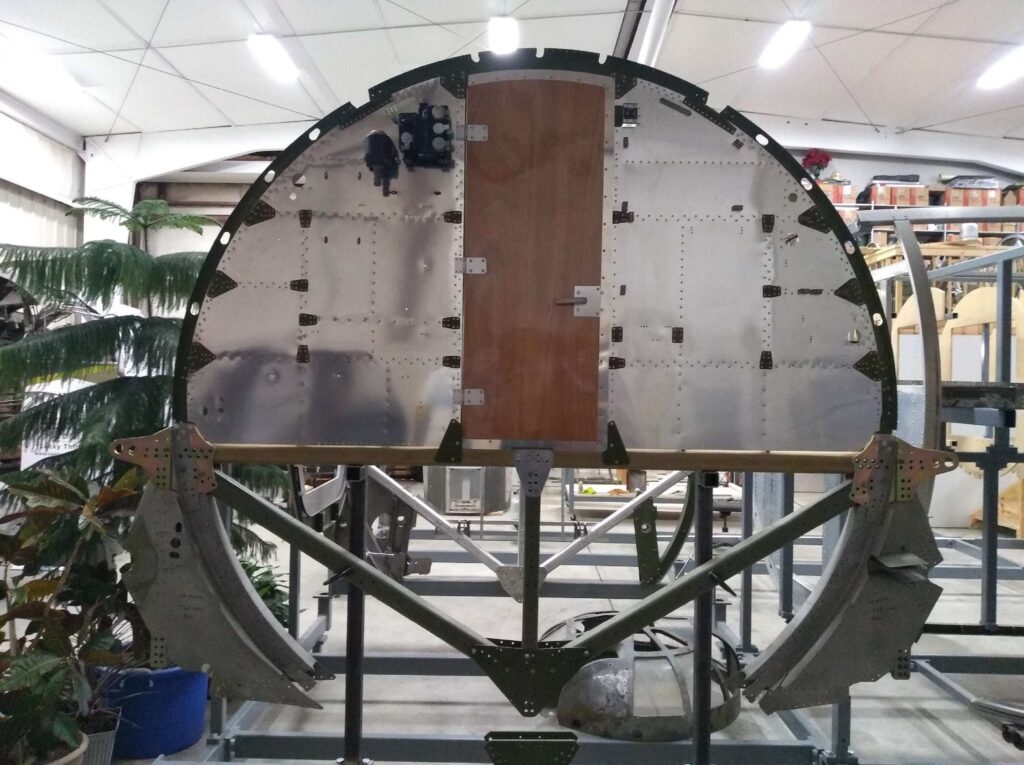

Wanted to share some photos Ray sent of the Station 5 bulkhead for Lucky Thirteen.

To briefly recap, the wingspars for the Boeing B-17 constituted the lower half of Stations 4 and 5. Together with the outer compression struts, the carry-thrus for the wingspars create a box assembly, which supports the weight of the entire aircraft.

The carry-thrus for 4 and 5 have been under steady restoration and, as of yesterday, Station 5 has been elevated on its workspace so that we can focus on its carry-thru. When this work reaches the appropriate point, the assembly will be mounted into the forward fuselage jig and the process repeated for Station 4.

This update is an exciting one for us – we now have a ball turret hand control!

This is a huge step forward in rebuilding the turrets for Boeing B-17F Lucky Thirteen.

Lucky Thirteen carried a Type A-2 ball turret built by Briggs Manufacturing of Detroit, Michigan. While the turret was designed by Sperry Gyroscope, the turret was made by Briggs as Sperry lacked the ability to produce them in-house. Briggs was the single largest producer of ball turrets during the war. Used from B-17E 42-2505 up through B-17G-20-BO, the Type A-2 can be distinguished from later models by its plexiglass side caps and large hand control assembly. The rectangular assembly underneath the handles house the turret control’s fire switch housing. The A-2A, which was used on all subsequent G-models following G-20-BO, shortened the hand control by removing the lower housing and leaving its wiring exposed.

It should be noted that the Consolidated B-24’s ball turret, the Type A-13, underwent these same changes. We do not know the block numbers for when the B-24 made this change. However, we do know that the A-13 did not receive a suffix to coincide with the A-2/A-2A.

The controls for the ball turret consisted of a pair of cork handles which operated in tandem. Turning the handles turned the turret in the direction of the bottom of each handle. For example, turning the handles right would turn the turret left and vice-versa. Unlike most turrets, the ball turret’s hand control lacked a dead man’s switch. This meant that the gunner did not have to hold a button down in order for the turret to operate. This made the turret dangerous to operate for careless personnel and a later adapter kit allowed unit to install a dead-man’s switch by replacing the cork handles with plastic ones.

Like the handles, the firing buttons also worked in tandem, so that either switch would fire both guns. If desired, each gun could be individually selected by activating/deactivating the firing solenoids via the turret’s fuse box, mounted on the internal ammo magazine. (It is a myth that the B-17 ever carried externally fed ball turrets.)

This unit has been spray-painted green in its past and its dataplate removed. Thankfully, the internal gearing and wiring is in good condition. We hope to soon return its Briggs gray paint scheme and recreate the missing dataplate.

Locating a Type A-2 hand control was difficult, as was ensuring that said control was a Briggs model. We were able to purchase this unit from the Planes of Fame Air Museum in Chino, California. This was accomplished entirely using money donated to the project from our supporters. To you, we are exceedingly thankful.

Something to consider –

We are extremely close to having all the pieces necessary to restore the ball turret’s internal gearings for a live bench test. So far, we lack the hydraulic reservoir tank for the transmissions (the turret’s motor was electric) and our fuse box assembly is completely hollow, requiring extensive wiring. Once these issues are rectified, we can begin restoration of the ball turret’s internal gearing in earnest. If one day we are able to raise enough money to purchase the ball and hanger assembly, we hope to be ready to install the working motor/gearing right away!

*Since this update was made, a hydraulic reservoir has been acquired

Speaking of Planes of Fame

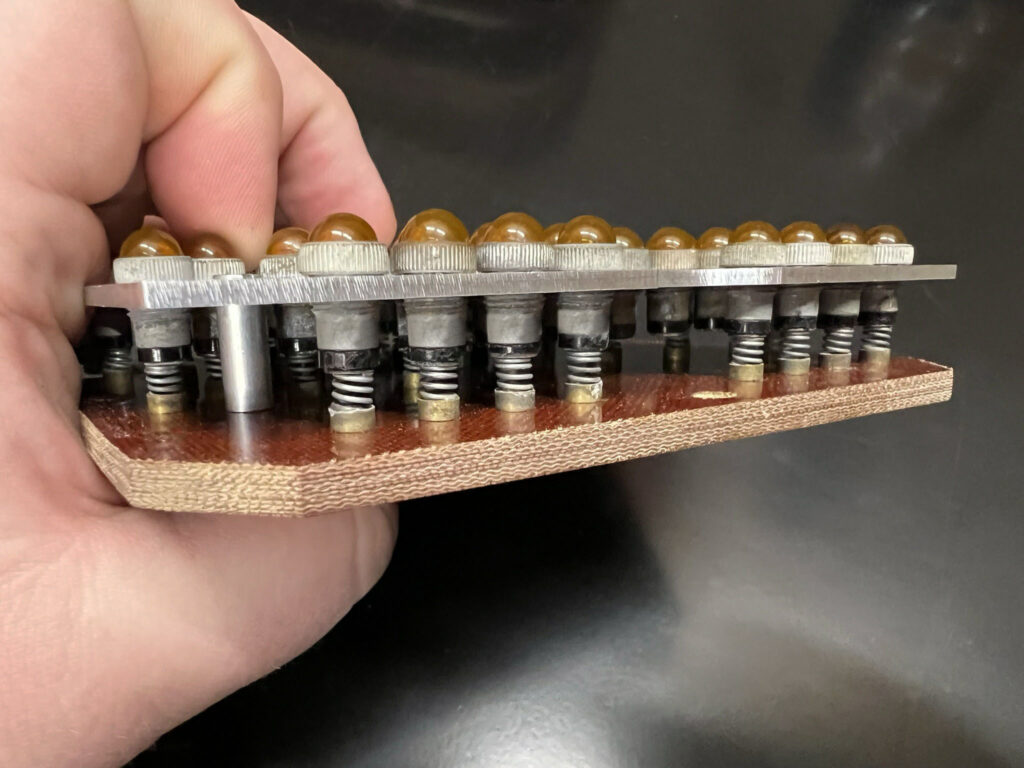

Back in April 2023, we rebuilt the bombardier’s Bomb Rack Indicator Panel. This was a series of lights mounted in the bombardier’s panel which indicated hard points in the aircraft’s bomb bay. When a bomb was loaded, a light shown to signal the bomb was there. These lights operated using spring contacts, which pushed up against each tiny bulb. While we were able to recreate the panel, the original manufacturer, Korry Electronics of Everett, Washington, no longer carried these pieces.

Thankfully, the team at the Boeing B-17E Desert Rat Restoration Project still had her original indicator panel and it was still wired up. They provided us with measurements and photographs so that we could recreate these pieces. Sharing the references with Planes of Fame, they ironically located an original example for their aircraft – which was slightly different from the one found by Desert Rat but more in alignment with the original drawings. These guys put an incredible amount of work into recreating these TINY fiddly pieces so that Piccadilly Lilly II and Lucky Thirteen would be able to operate their indicator panels.

Our special thanks to our friends at Desert Rat for their reference material and at Planes of Fame for their incredible work.

The newly arrived Type A-2 Ball Turret Hand Control. Shown with a baseball for scale.

The green paint is not period. This unit was originally gray.

Photo taken 14 February 2024.

The interior of a Briggs-built Type A-2 Ball Turret.

Note the gray interior. This is typical of Briggs built turrets. Ball turrets made by Emerson Electric of St Louis, Missouri had dark green interiors.

Manual illustration of the Type A-2 Ball Turret’s primary motor and gearing components.

Manual illustration of the Type A-2 Ball Turret’s primary motor and gearing components.

The double power unit, consisting of the two hydraulic transmissions and center electric motor, were produced as a single assembly by Vickers of Detroit, Michigan.

The Elevation Gear Assembly for the Type A-2 Ball Turret. The red handle is for moving the turret should the power fail.

Photo taken 19 August 2023.

One of the two-part gearings for the Type A-2 Ball Turret’s Azimuth Assembly.

The larger assembly which connects to this is currently undergoing a cleaning.

Photo taken 19 August 2023.

One of the two Double Power Units for the powered gun turrets on Lucky Thirteen.

The A-1 Upper Turret and A-2 Ball Turret both used the same motor design.

Photo taken 23 December 2020.

The Briggs ball turret magazine sits on my dining table.

This assembly is currently undergoing restoration.

Photo taken 29 October 2020.

The Type A-2 ball turret switch box.

As you can see, it is in need of wiring, a replacement faceplate, and cannon plugs for its side connections.

Photo taken 14 July 2021.

Early acquisitions for the Type A-2 Ball Turret:

A gun sight bracket, spent shell chute, portion of control linkage, and partial intercom foot switch.

Photo taken 17 May 2019.

Fully-restored Type A-2 Ball Turret gun charging handles.

Photo taken 11 December 2021.

The Bomb Rack Indicator Panel alongside the newly-recreated Korry Spring Contacts.

Photo taken 14 February 2024.

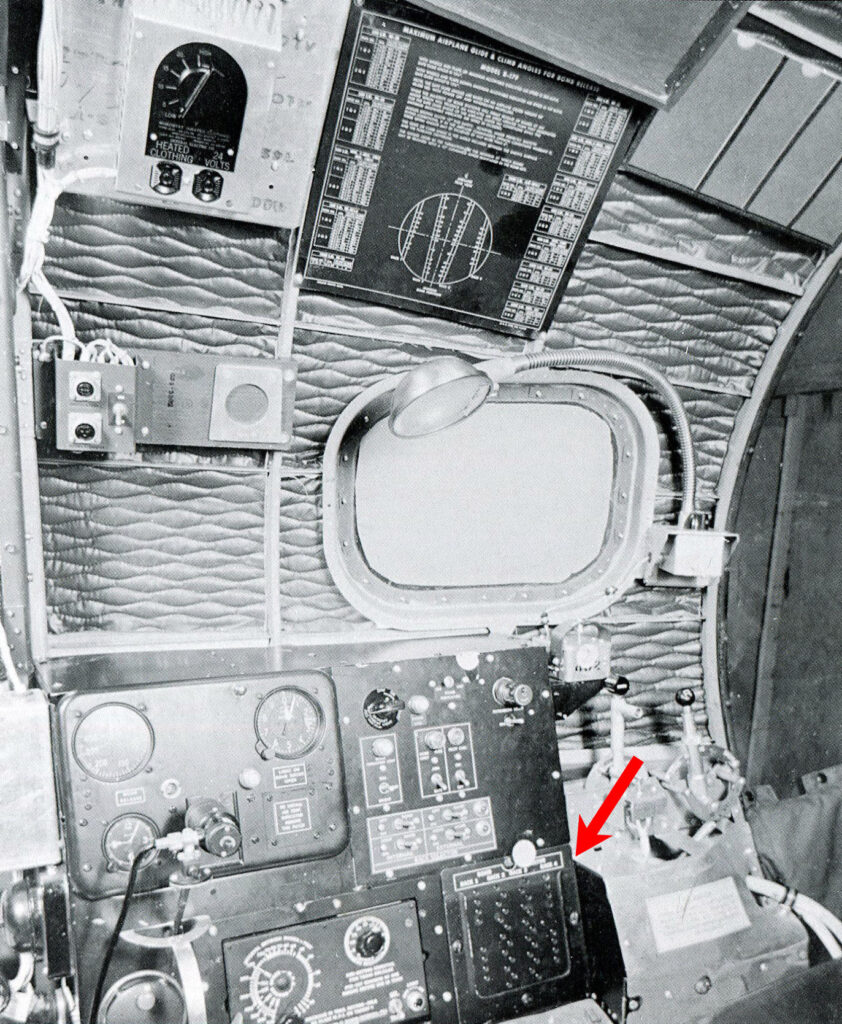

The Bomb Rack Indicator Panel is highlighted in this photo of a bombardier’s position aboard a B-17F very similar to Lucky Thirteen.

F-models had 42 hardpoints in their bomb bays, with the panel including an extra 14 bulbs as spares.

With B-17G-45-BO, the electro-mechanical bomb release system was replaced with an entirely electric system. When this occurred, the number of hard points dropped to 24.

The recreated Korry Spring Contacts in place.

Photo taken 14 February 2024.

The Korry Spring Contacts are installed in the Bomb Rack Indicator Panel for “Lucky Thirteen.”

The plugs for where each contact will be wired is visible here.

Photo taken 14 February 2024.

Side view of the Bomb Rack Indicator Panel showing the Korry Spring Contacts pushed up against their respective bulbs.

A perfect fit.

Photo taken 14 February 2024.

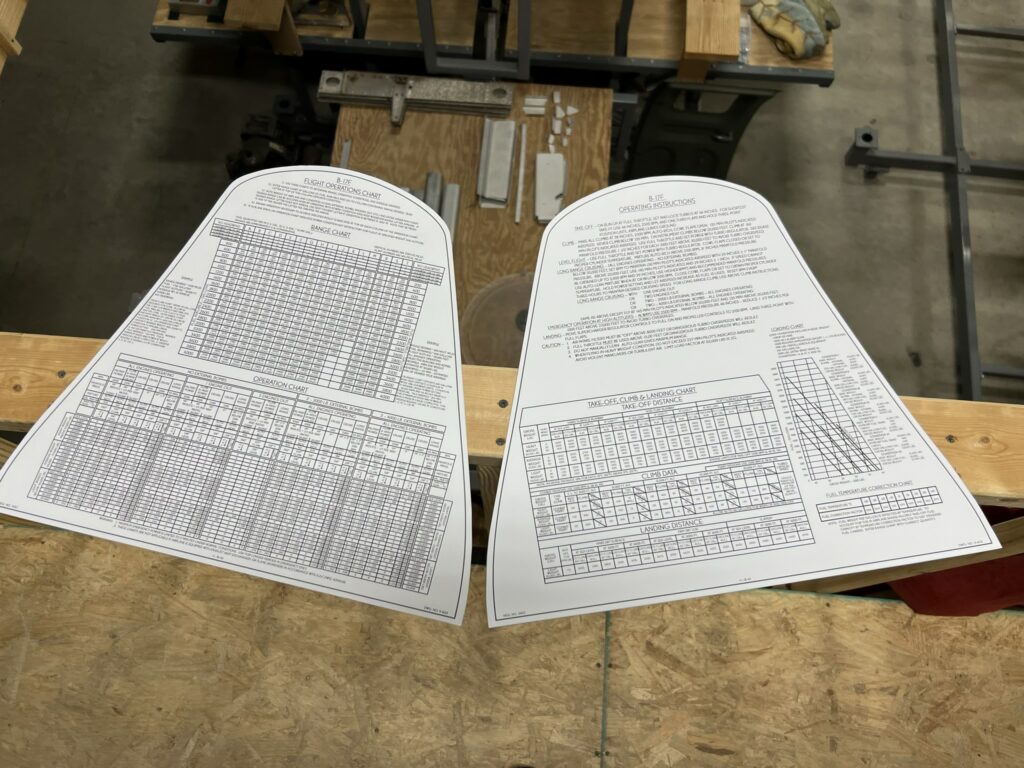

I thought I would begin this update by answering a common question since the “Masters of the Air” series premiered – what are those charts behind the pilots’ heads?

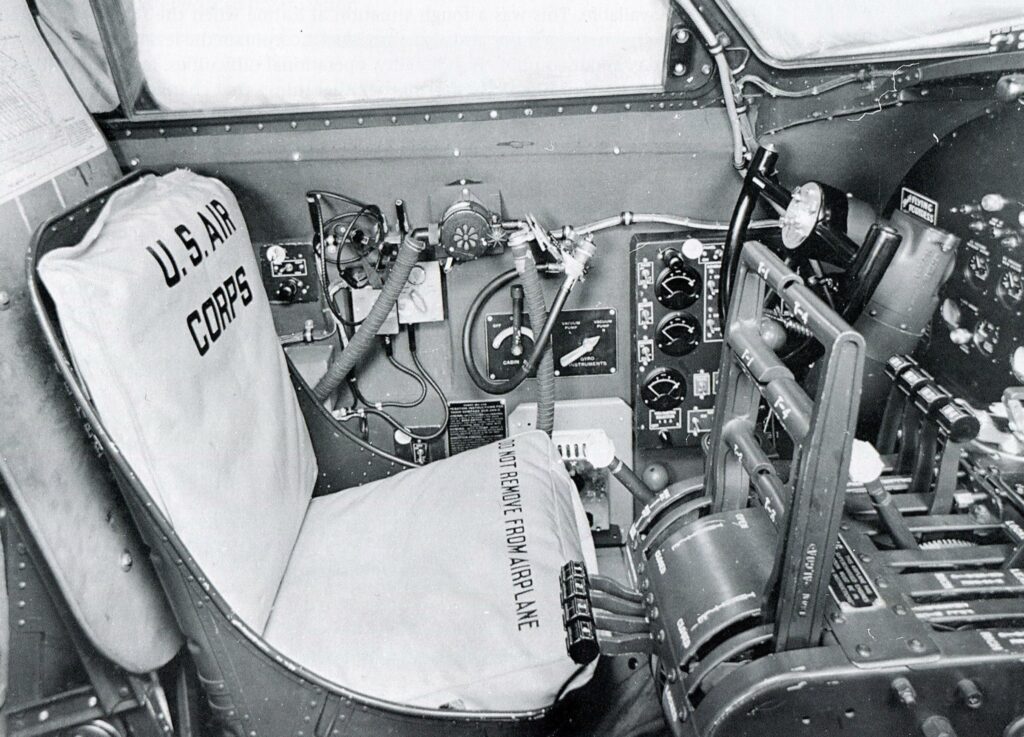

These charts were the Operating Instruction and Flight Operations Charts. The information contained within included range estimates based on fuel quantity, aircraft weight, and headwind; power settings based on weight, altitude, and number of engines operating; takeoff, climb, and landing distances based on weight, headwind, runway hardness; weight figures based on loadout and fuel quantity; and fuel weight correction based on temperature. The idea behind these charts was to keep the information handy so that consulting the Operations Manual was not necessary.

The charts were glued to the pilots’ armor plates, which were bolted to the backside of their seats. The charts were made of 200 grade cardstock and the armor plates .25” thick RHA steel plate. RHA steel plate is not freely sold on the market so if anyone has access to some sheets and would be willing to help the rebuild of Lucky Thirteen, please let us know!

We recreated these charts several years ago and had honestly forgotten to feature them in an update. An original set of armor seat plates was donated to us by Brian Freer in the UK back in 2019 and are currently awaiting restoration. The cardstock for the charts was donated by Monadnock Paper Mills of Bennington, New Hampshire. Templates were made of these plates and provided to the team at the National Museum of the US Air Force, along with the charts’ predecessor, for installation into Memphis Belle. While many of our charts were installed, the Belle‘s cockpit armor plates were ultimately not included in the restoration. The Operating Instruction and Flight Operations Charts were used from blocks F-35-BO through G-95-BO, which equates to roughly March 1943 through October 1944.

Next up are the bomber’s cabin lights, which were CAD modeled by volunteer Howard Lawson in Jacksonville, Florida and 3D printed by Schmidt Proto of Minneapolis, Minnesota.

The B-17’s carried three cabin lights, with two in the radio compartment and one above the navigator’s desk. These lights were simple overhead lamps with toggle switches mounted to one side. Older aircraft used aluminum fixtures while, starting with F-95-BO (roughly May 1943), the fixtures were made of black tenite. The black tenite models stayed in use throughout the rest of the B-17’s production.

We originally recreated these lamps based on the dates in which they were in service, though we now believed that we may have erred. The B-17’s blueprints do not include serial numbers for Douglas and Lockheed-Vega production changes, which usually requires us doing additional research. In this case, we cannot find any references confirming when Douglas made the switch from aluminum to tenite lamp fixtures. Context is difficult to establish – sometimes Douglas was behind Boeing in changes, and other times they were ahead. As it stands, we have a gut feeling that the aluminum fixtures MAY be more accurate than the tenite ones. Until we have a set of aluminum light fixtures, we will hold onto these black ones.

The aluminum fixtures are also needed by the team working on B-17E Desert Rat, so if anyone has the skills to fabricate the aluminum type fixtures and is willing to do so, your work would be going to help TWO B-17s. The blueprints for them are here:

9 February 2024 was an interesting day. My nephew, age 11, was required by his school to spend a day job shadowing. So, he asked to come to the hangar.

Ray is an awesome teacher and helped him recreate a bracket which went into the tail gunner’s hatch assembly on the Lake Dyke B-17G.

The recreated Operating Instruction and Flight Operations Charts for Lucky Thirteen.

Special thanks to Karl Hauffe who found the original prints for these back in 2019.

Photo taken 9 February 2024.

The cockpit of a Boeing B-17F identical to Lucky Thirteen.

The Operating Instructions Chart is visible on the armor plate here.

Pilot seat cushions recreated for Lucky Thirteen as thanks for working on Memphis Belle. Truly one of the great honors of my life.

A later version of these cushions read “Army Air Forces” and had “US Army” written on the sides.

Photo taken 10 September 2020.

A screenshot from Episode 3 of “Masters of the Air.” The Operating Instruction and Flight Operations Charts behind the actor’s heads are visible here.

This episode featured the infamous Schweinfurt-Regensburg strike of Operation JUGGLER. Lucky Thirteen was a participant in this operation and when completed will be the sole representative of this, the bloodiest period in aviation history.

Screenshot from the training film “How to Fly the B-17.” The aircraft featured in this film is 42-30641, an aircraft just six days younger than Lucky Thirteen.

The actor playing the instructor is Oscar-nominee Arthur Kennedy. Note the Flight Operations Chart behind his head.

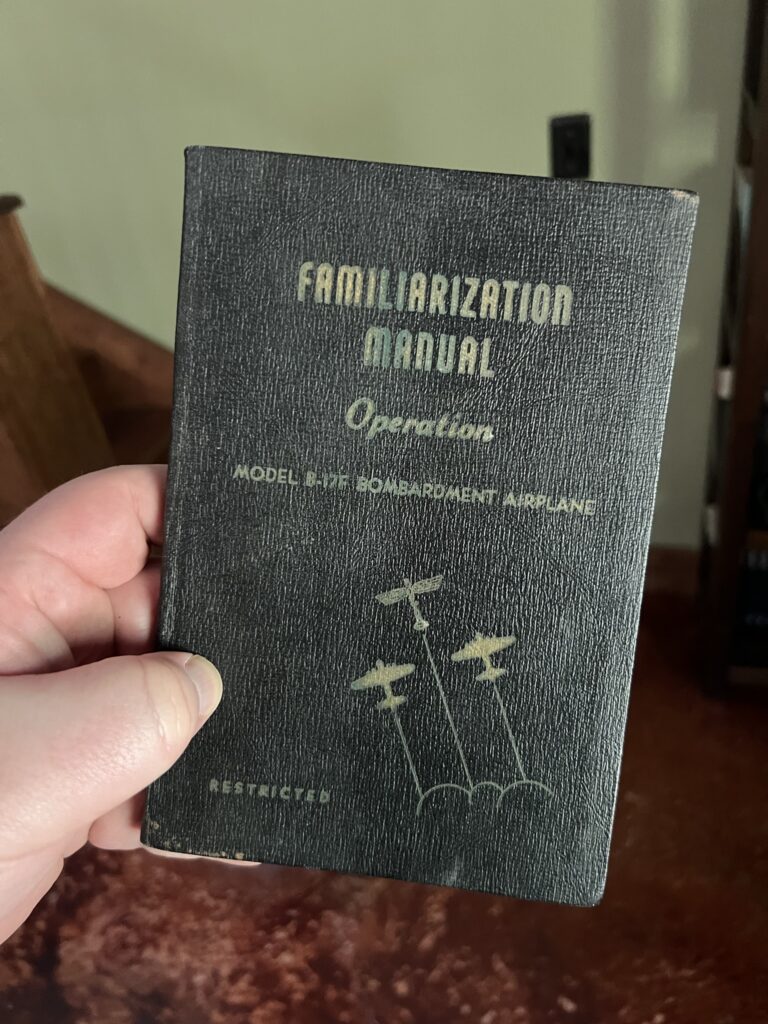

The B-17F Operation Familiarization Manual donated by Bill Spirk.

Photo taken 29 April 2023.

The cockpit armor plates for Lucky Thirteen shortly after arriving from Great Britain.

Photo taken 9 August 2019.

1LT Bob M. Welty of the 398BG peers over the armor plate on his seat.

The rather horrific effects of German 20mm autocannon fire on a 92BG B-17 cockpit.

Field modifications to increase forward facing armament, and the slowly increasing range of US escort fighters, resulted in frontal attacks falling out of favor throughout the latter half of 1943. Rocket armed heavy fighters began firing into formations to spread the bombers out, allowing interceptions to take place piecemeal. This too would fall out of practice once the US droptank issue was fully resolved.

Photo taken 26 July 1943.

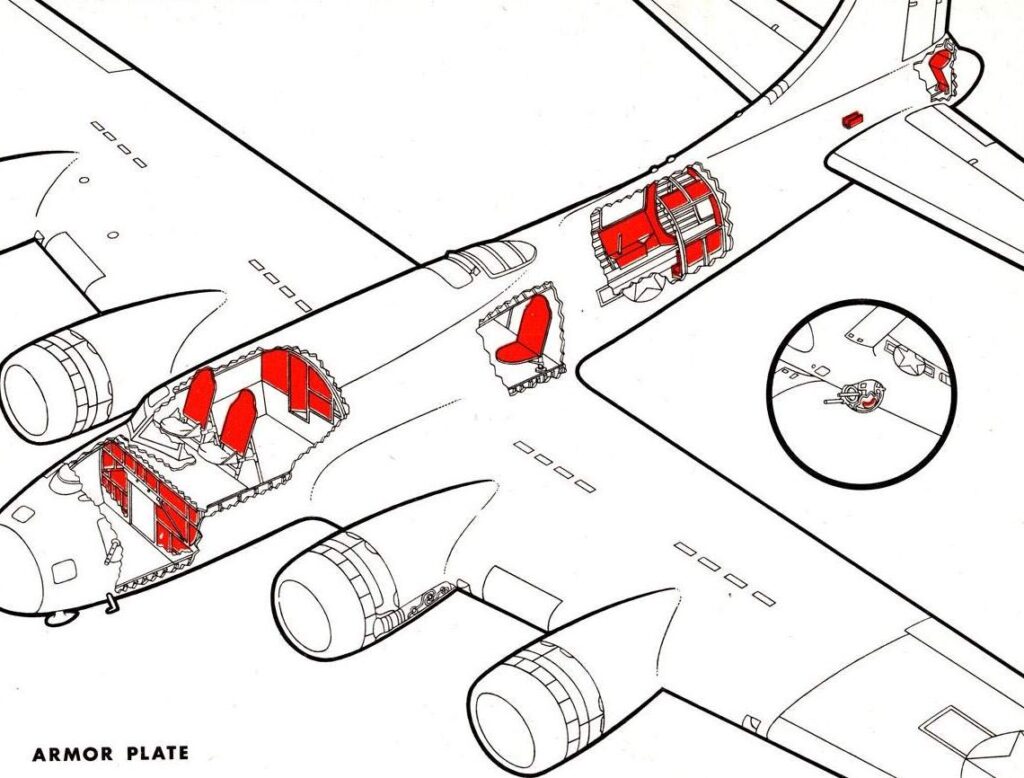

Chart showing the armor complement aboard a typical F-model B-17.

The setup aboard Lucky Thirteen was identical to this, though her radio operator’s seat was a Cramer posture chair rather than a bucket seat with an armor plate.

The newly completed tenite cabin lights.

Photo taken 11 December 2023.

TSGT Normand J. Vicknair of the 384BG at the radio operator’s position aboard a B-17G. The tenite-type cabin light is visible at the top.

Also note the A-2 carbon tet extinguisher bracket on the Station 5 bulkhead.

The 384BG was the same unit with which Lucky Thirteen served.

Stateside photo showing the navigator’s position aboard a B-17F.

The aluminum type cabin light can be seen here.

The long-awaited “Masters of the Air” series on AppleTV has now been released. The production is centered upon the 100BG and heavily features late F-model B-17s like Lucky Thirteen. We did a little consulting for the series and genuinely hope it generates interest from future generations.

And it bears noting that Lucky Thirteen is the only F-model project representative of the latter-half of 1943 – the bloodiest period is aviation history.

This week’s update on Lucky Thirteen features a potpourri of steps forward on the project.

First up is a Type G-11 Solenoid donated by Howard Lawson of the Virtual WWII B-17G Bomber Project. Manufactured by radio giant Magnavox, the G-11 was one of the more common gun firing solenoids used by the USAAF in the Second World War. It fitted over the backplate of the AN-M2 .50 caliber machine gun and, when activated, used a powerful electric magnet to trip the gun’s trigger bars.

Lucky Thirteen needs four such units as they were used on the bomber’s powered turrets. Howard’s donation is a huge step in that effort, and we are incredibly thankful for him coming to us with it!

Next up is a recent acquisition of an unusual sort – the bomber’s life raft accessory bag.

The B-17’s life rafts were housed in a compartment above the aircraft’s bomb bay. The open area created by the ‘turtle deck’ above the bay allowed for a small storage area. A pair of baffles inside created three cubby holes, with the ones on either side holding a Type A-2/A-3 Life Raft. The life raft accessory bag was meant for the center hole, however the tightness of this space meant that often the bag was kept inside the fuselage. The two life raft doors were opened by T-handles in the roof of the radio compartment.

Our friend Brad Hayes in Hawaii notified us of this piece, and we quickly picked it up based on a rare black-and-white photograph of the bag stowed in the life raft compartment of a B-17. Unfortunately, checking with Richard Kerr, we discovered that our bag was not accurate to 1943. Though the two are identical in stitching, the older bag was yellow rather than olive drab.

Speaking of pads, there are only a couple left to go for the interior of Lucky Thirteen. I know some of you restore wartime vehicles like Jeeps and old trailers – if any of you have some remnant OD canvas material you would not mind parting with, please let us know. Our needs are very small as we only need a couple yards worth at most and our original remnant is too small to get the last couple pads from.

Last is a piece from volunteer Bob Jacoby down in Jacksonville, Florida. Bob is a super awesome guy, but a car accident left him unable to attend the event at Triple Tree last year. His arm healing, Bob thought he might bend up a piece which will go toward a larger project that we have been experimenting with – the radio room’s hatch gun.

The B-17’s radio room gun went through several variations throughout the war. The blueprints acknowledge three major types: a bar which mounted through the Edgewater adapter, the ring mount type, and a type which held the gun using a K-6 mount. The bar mount saw use from blocks F-30-BO through F-70-BO, the ring mount from F-75-BO through G-55-BO, and the K-6 mount from G-85-BO through G-105-BO.

That said, there was far more to it than this. Aircraft without radio hatch guns were routinely modified to carry them, and the Cheyenne Modification Center likewise for a time installed a variant of their own which replaced the lower part of the window with a large cast piece. However, it is the ring type mount which is accurate to Lucky Thirteen.

Volunteer Bob Hachmann CAD modeled the ring mount assembly for Lucky Thirteen with the intention of using its center T bracket as a case-study for casting large aluminum parts. You see, since it seems unlikely that original turret body components will ever come to us, we must continue under the assumption that we will have to make our own. Since the turrets will require massive casting projects, the relatively large size of the radio hatch gun will make an interesting test case for us as we move forward.

It was in response to this that Bob Jacoby formed the outer ring which the casting will, when made, will fit inside. Thanks Bob!

Howard’s newly donated Type G-11 Solenoid.

Lucky Thirteen is in need of additional examples and we recently learned that there is an extra piece which locks these in place, which is missing from our examples. If you can help with these needs, please let us know!

TSGT Everett A. Dasher (303BG) poses with a Type A-2 Ball Turret while on a War Bond tour of the United States.

The Type G-11 Solenoid is visible through the window on the right gun.

On 19 May 1943, a round from a Ju-88 deflected off of Asher’s parachute buckle and lodged itself into his spine. Asher lived with this hunk of metal for the rest of his life, passing away at age 85 in 2004.

TSGT Robert M. Dawson (379BG) inspects the left gun of this Type A-2 Ball Turret.

The hatch for accessing the gun and it’s firing solenoid is visible on the left.

The newly acquired Life Raft Accessory Bag.

We were surprised to learn that it was not accurate to wartime aircraft. The tips of each strap are dipped in bee’s wax, which is typical of wartime practice.

Photo taken 1 December 2023.

The wooden baffle is removed from this Boeing B-17’s life raft compartment to reveal the Life Raft Accessory Bag inside.

A wartime example of a Life Raft Accessory Bag.

A training mock-up of the Boeing B-17’s life raft compartment.

The Type A-2 Life Raft is deflated and folded here.

A Boeing B-17 flight crew undergoing a life boat drill. The baffle separating the life raft from its accessory bag can be seen in the stowage compartment here. Because this is a metal baffle, as opposed to a wooden one, it suggests that this is an older B-17.

Note the airman on the right – he is holding an older style, two-bag Gibson Girl emergency radio.

The SCR-578-A Gibson Girl Emergency Radio for Lucky Thirteen.

Photo taken 4 June 2023.

The T-handles which open the Boeing B-17’s life raft doors, visible here above the radio compartment.

We are currently in the process of replicating these handles.

Note the wooden piece at the upper left. This is used to tie down the radio hatch gun’s barrel when not in use.

The outer ring for the radio hatch gun is formed.

Photo taken 26 November 2023.

Manual illustration of the radio hatch gun on a Boeing B-17F.

Note how the ammo chute reaches the gun. A section of left-hand and right-hand chute are mated together so that the chute faces upward when attaching to the gun.

If anyone has any Hughes-type chutes that they would be willing to see go toward Lucky Thirteen, please let us know!

The stowage clamp for the radio hatch gun aboard Lucky Thirteen.

Photo taken 18 April 2023.

Swiss personnel inspect the radio hatch gun aboard High Life (42-30080, 100BG). Note the straps for the stowage clamp hanging down.

High Life crashlanded in neutral Switzerland on 17 August 1943 during the infamous Schweinfurt-Regensburg strike.

This operation was the third combat mission for Lucky Thirteen.

From the “Masters of the Air” premiere last night.

Congratulations to Hangar Thirteen volunteer Karl Hauffe. Looks like you’re famous now!

Some pics showing Ray’s work on the Lake Dyke B-17G.

Like Lucky Thirteen, this aircraft was built under license by Douglas, which meant that the ribs and stringers were originally dipped in zinc chromate. We are replicating this process.

Progress on the aft fuselage of the Lake Dyke B-17G.

Photo taken 8 January 2024.

Note the unusual colorization. This is a result of dipping the ribs and stringers instead of painting them. Multiple wreckages reveal that this was original practice.

Photo taken 8 January 2024.

The next step will be to apply the ALCLAD ink stamps to the bare aluminum. We have carefully scanned original wreckage into the computer and have the ability to reapply the markings found on wartime bare aluminum.

Photo taken 8 January 2024.

Ribs and stringers for Lucky Thirteen and the Lake Dyke B-17G are dipped in zinc chromate and hung to dry. This is the same method Douglas practiced during the war.

Photo taken 8 January 2024.

The holidays were a hectic time and things did slow down with 2024. My family spent most of 2023 working to expand our woodshop, which is the reason my posts were not as regular as usual. We are still not finished but the cooler weather is allowing us to get a lot more finished (those of you who have experienced a South Carolina summer know what I am talking about).

That said, work on Lucky Thirteen continues. In fact, I must say that the 2023 holiday season saw more financial donations to the project than we have ever gotten. Without asking, our supporters donated more than the entirety of the month-long fundraiser in May. Truly, we are at a loss for words.

Thank you.

In early December we talked about our recent acquisition of a Type A-2 carbon tetrachloride fire extinguisher. The standard Boeing B-17 came equipped with three steel carbon dioxide units and two brass carbon tet units. The carbon tets were produced by Fyr Fyter of Dayton, Ohio, and since then, I have been able to cosmetically restore this extinguisher. Another unit has already been restored by volunteer Chris Ely in Missouri and is awaiting its transfer here. In theory, we are very close to knocking out the carbon tets for Lucky Thirteen.

One issue that remains is the extinguisher’s bracket. Supporter Robert Charles Langham recommended we check out replica mounts made for Ford GPWs, which are extremely similar to the A-2’s original mount. The only difference between the two is that the aircraft mounts are black, sit flush against the wall (easily solved by unscrewing the standoff brackets) and have a slightly different top piece. So, we went ahead and ordered a pair.

However, we have noticed some discrepancies between various surviving A-2 brackets online and we have talked about possibly leaving these GPW brackets alone because of this fact. However, we are nevertheless investigating a way to alter the upper part of the GPW bracket to make it match the manual illustrations, just in case.

Speaking of extinguishers, the cigar bands for the two remaining A-17 steel extinguishers are now engraved. These bands still need to be bent into shape, and volunteer Bill Winter is currently working to replicate the missing clasps for the extinguisher horns. Once these bands are complete, the second A-17 for Lucky Thirteen can be crossed off as complete.

As for the third unit, we are facing some difficulty. We once managed to assemble a third unit but, during a visit to an extinguisher shop, the brass assembly was ripped in half, leaving the bottom threaded portion stuck in the cylinder. Removing it seems almost impossible without destroying the cylinder, and if we can manage to get it out, the brass assembly would still have to be welded back together. Hopefully this situation can be resolved as it is unlikely that we will find another A-17.

The beginning of the month saw a visit from our friend Max Pearsall, finally meeting face-to-face for the first time. Some of you may recall that Max, currently serving with the US Air Force, contributed a seatbelt, Hughes ammunition chute, and a gigantic K-17 strike camera to the project back in 2021. When Max came to visit, he brought some more pieces to project, including a pair of D-6 bomb shackles and another Hughes ammunition chute.

The B-17’s bomb racks held a total of 42 hard points and were equipped to hold 24 Type B-7 shackles and two Type D-6 shackles in various load patterns. These shackles attached to the lugs of the bombs when loading, clipping to the racks and intertwining with the bomb release boxes. When activated, the release box would, by pulling the levers on the shackle, arm and release the bomb. The B-17’s rated internal load was 4,000 lbs, with the maximum internal load being 6,000 lbs. An additional 8,000 lbs could be carried on a pair of external racks, though this was rarely done due to how much they affected performance. The B-7 shackle was rated to hold bombs up to 1,100 lbs; the D-6 was rated up to 2,000 lbs.

Lucky Thirteen carried a pair of M34 2,000 lb bombs on 27 August 1943, during a strike on the Blockhaus d’Éperlecques near Watten, France. A ‘hard target’ of concrete bunkers, this was the first US 8AF operation against a V-weapon complex. Since the bunkers were still under construction, the bombing was unusually effective.

Special thanks to Max for these donations! The Hughes type ammunition chute is the third so far to come to Lucky Thirteen. These chutes were single-direction only and so far, all have been right hand feeds. Right hand feed chutes can be distinguished from left hand chutes in various ways, the easiest being the color of the labels: green for right, red for left. Lucky Thirteen was filled with a multitude of Hughes ammunition chutes, both left and right, so if you have any you’d like to contribute, please let us know!

*Since this update was written, additional Hughes ammo chutes have been donated. Our right-hand needs are now fulfilled tough we still lack any left-hand feed chutes

The cosmetically restored Type A-2 carbon tet extinguisher, clasped in a Ford GPW extinguisher bracket.

Photo taken 19 December 2023.

The Type A-2 carbon tet extinguisher upon arrival. The red markings had almost entirely peeled away with age.

Photo taken 1 December 2023.

A color photo of an aerial photographer. Note the A-2 carbon tet on the wall behind him.

Two other areas are of interest in this photo:

First, note the fabric on the aircraft walls. While this is not a B-17, it is upholstered with the same material. Up through the F series, the nose, cockpit, and radio compartment of B-17s were insulated. On Gs, only the cockpit retained this fabric.

Second, note the camera assembly. This is a Fairchild K-17 strike camera mounted to Bruening-Winans A-8 shock assembly. The camera is connected to a Type B-2 intervalometer and the photographer is holding a Fairchild A-2 viewfinder.

This is the same setup as carried on Lucky Thirteen during her final mission. The only strike camera component still needed is the K-17’s mount. The K-17 could be mounted using either the Bruening-Winans A-8 or Robinson Aviation A-11. If anyone can help with one of these mounts, please let us know!

Just for fun – a photo of the A-2 and A-17 extinguishers under restoration.

Photo taken 19 December 2023.

A group shot of the two A-17s we currently have for Lucky Thirteen, along with the newly engraved cigar bands.

The A-17 closest to the camera still has its original band.

Photo taken 13 December 2023.

A callback to our recent excitement at locating the paper cup dispenser for Lucky Thirteen – the cup dispenser is laid beside the bomber’s crash axe.

We have since learned that Douglas was not following suit with Boeing on where they mounted these objects in the B-17. It now appears that, on Lucky Thirteen (who was Douglas built), these objects were not originally mounted beside one another.

Photo taken 13 December 2023.

Max’s newly donated D-6 shackles and Hughes ammunition chute.

Photo taken 6 December 2023.

Max’s grandad, 1LT Thomas F. Morris (far right, back row), with the crew of Mary Jane (42-3032, 2BG).

Max’s grandad completed his combat tour and returned home as a bombardment instructor. He stayed in the service and also saw action as a forward observer in the Korean War.

Mary Jane – a late Douglas-F like Lucky Thirteen – also survived the war. She was transferred to the 483BG in March 1944 and ultimately scrapped at Walnut Ridge, Arkansas in December 1945.

An M34 2,000 lb bomb mounted aboard a B-17G.

Note the chain wrapped around the bomb. This chain was purposely designed for the M34. The M34 was the largest bomb the B-17 could carry internally. The M59 was the only US bomb of larger size, weighing 4,000 lbs. It could only be carried by the B-17 externally.

Also note the armor plate on the cockpit door, an original of which was recently donated to the project.

A NOS 2,000 lb bomb hoist chain donated to the project and cleaned.

This piece was unique to the Type C-3A Bomb Hoist set. The original C-3 set contained canvas hoist straps rated at 300 lbs, 500 lbs, 1,000 lbs, and 2,000 lbs.

Photo taken 8 September 2020.

SSGT George S. James of the 305BG at the right waist position of a B-17F.

Note the ammo chute.

In the nose, tail, and radio room positions, lengths of left and right-hand feed chutes were coupled together so the chutes could twist in route to the gun.

This pad was recreated for by Matt Sturgell of Easy, South Carolina.

The pad mounts to Sta. 11 of the aircraft and serves to protect the tail gunner’s head as he crawls back into his position.

Photo taken 6 December 2023.