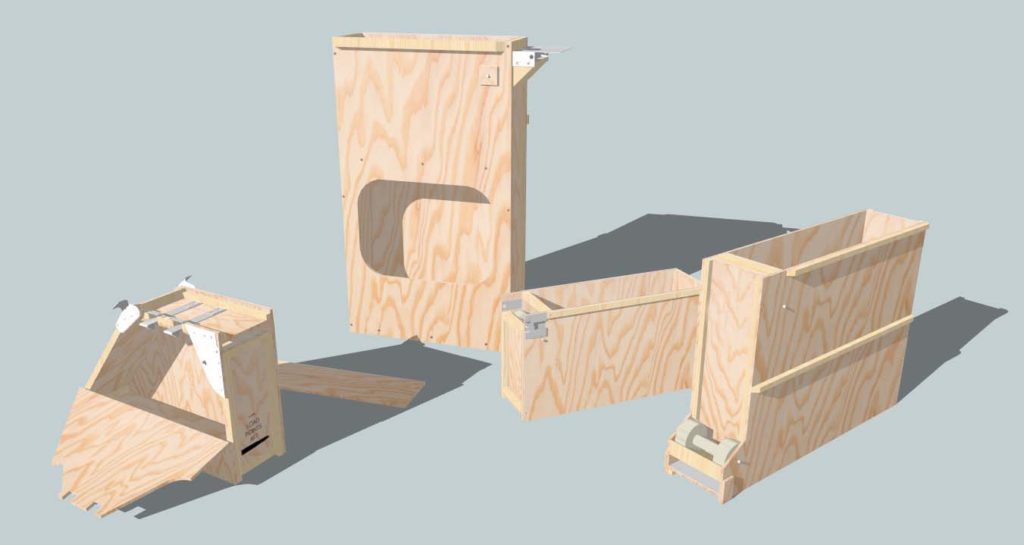

Regular followers will know that I have been itching to build Lucky Thirteen‘s eight wooden ammunition boxes for quite some time. Well, we have made some progress on that.

Our friend Bob Hachmann has offered to look into fabricating the metal bits that go on these boxes. This is particularly helpful as all contain a unique method of feeding the ammunition past the rollers and into the chutes.

Since we want these boxes to be as authentic as possible, it is imperative that their feed mechanisms function as they should. You never know when we might get to test them…

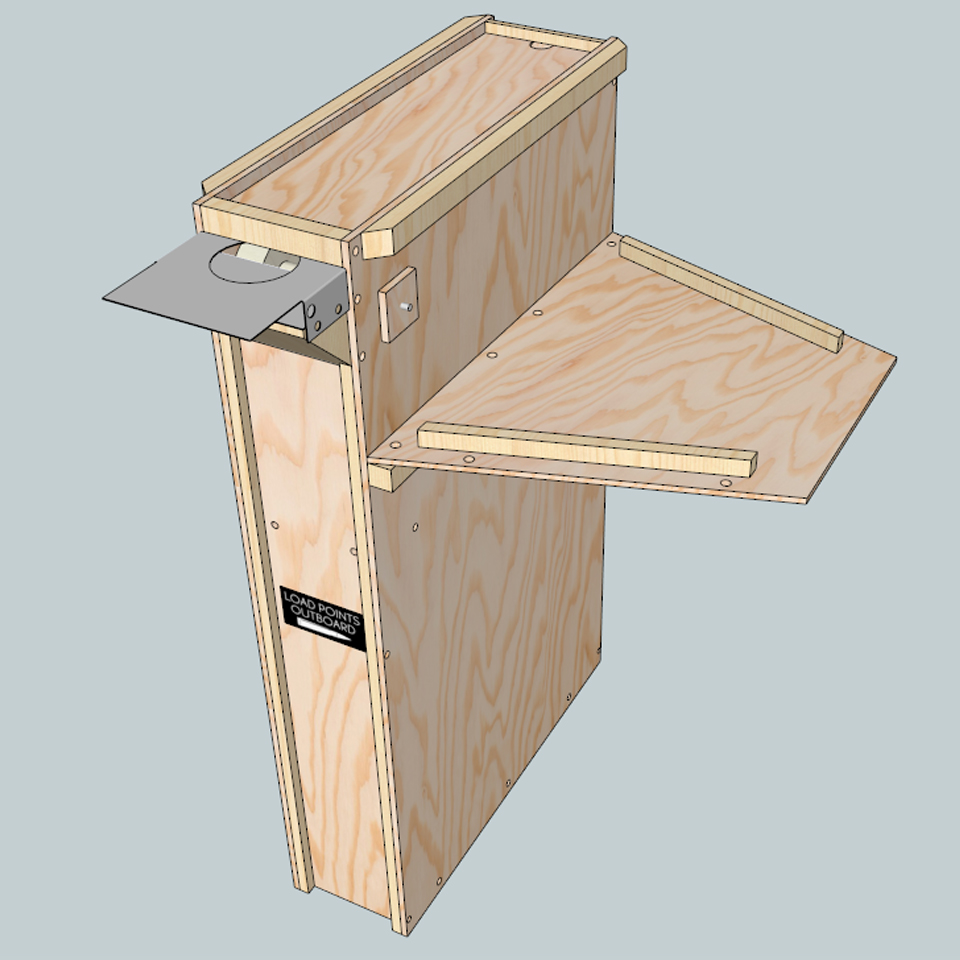

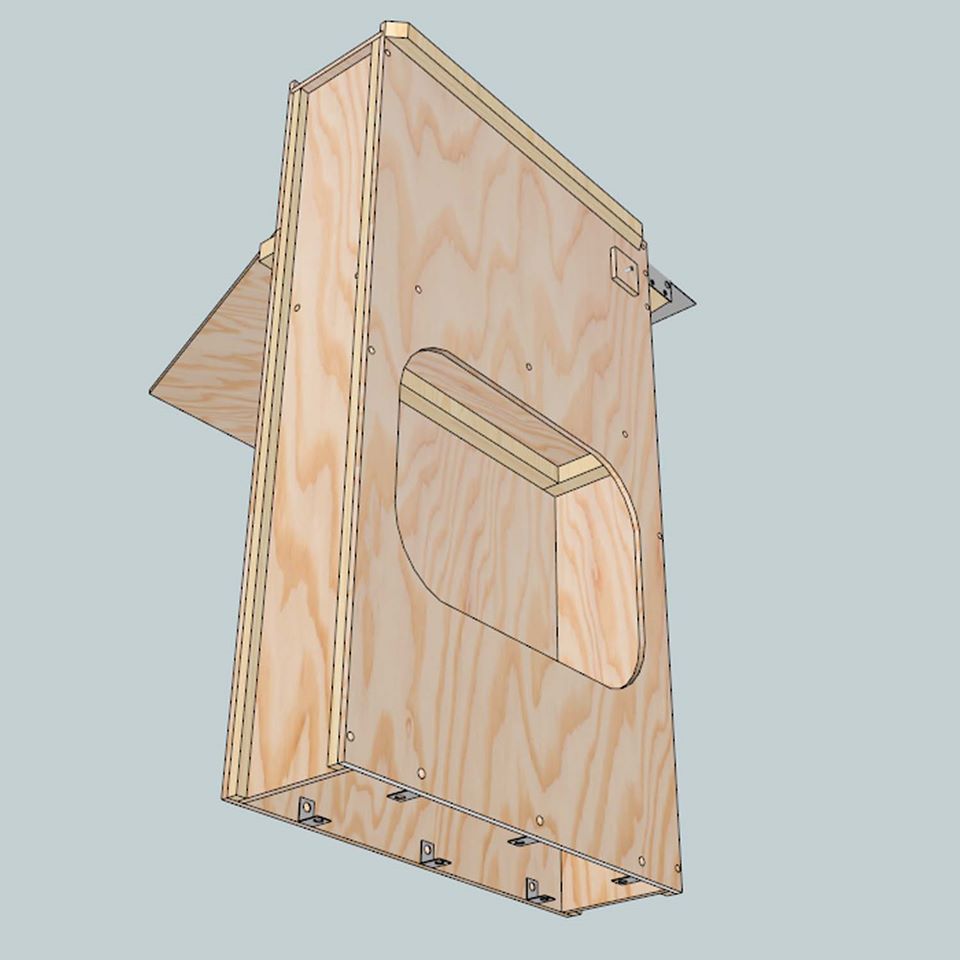

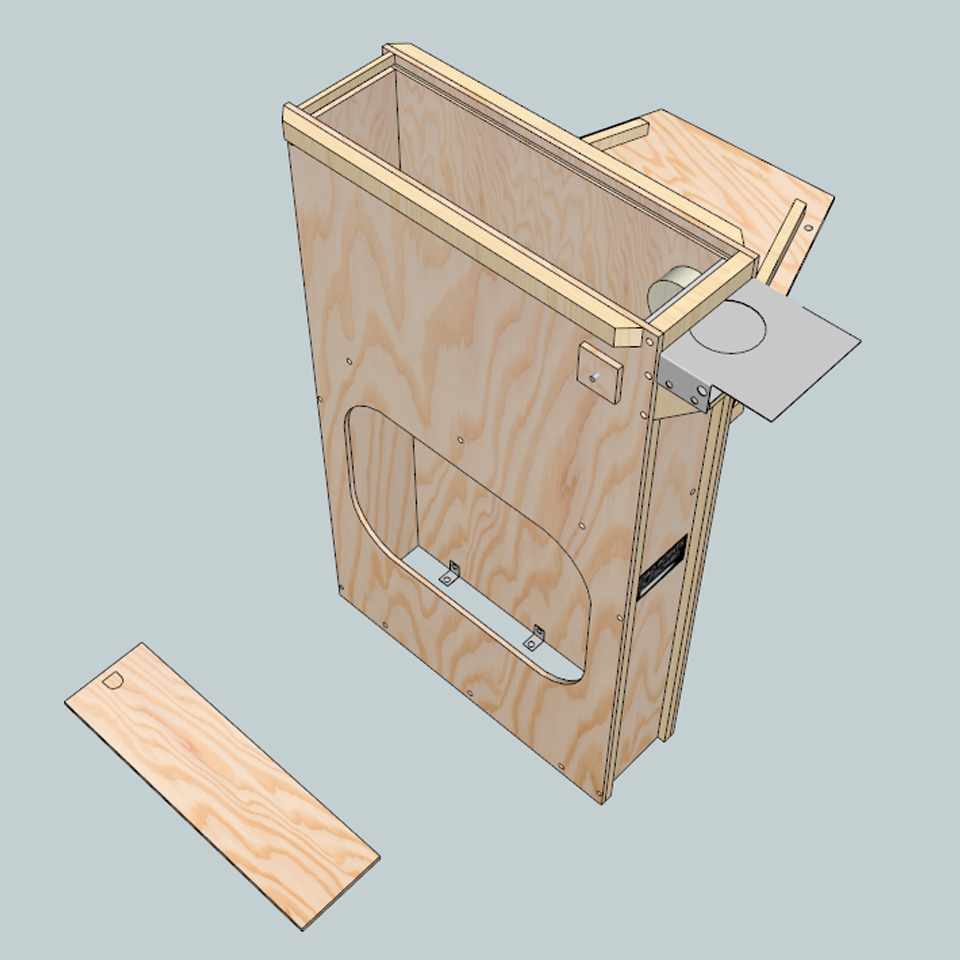

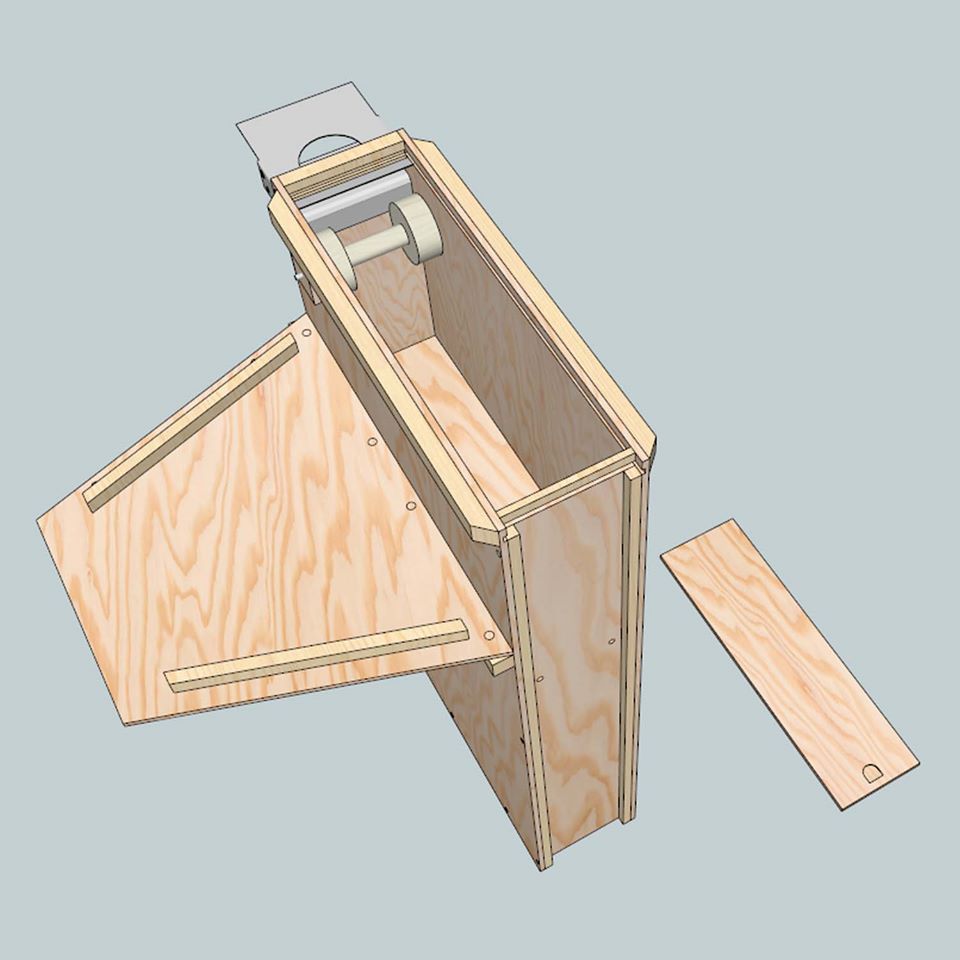

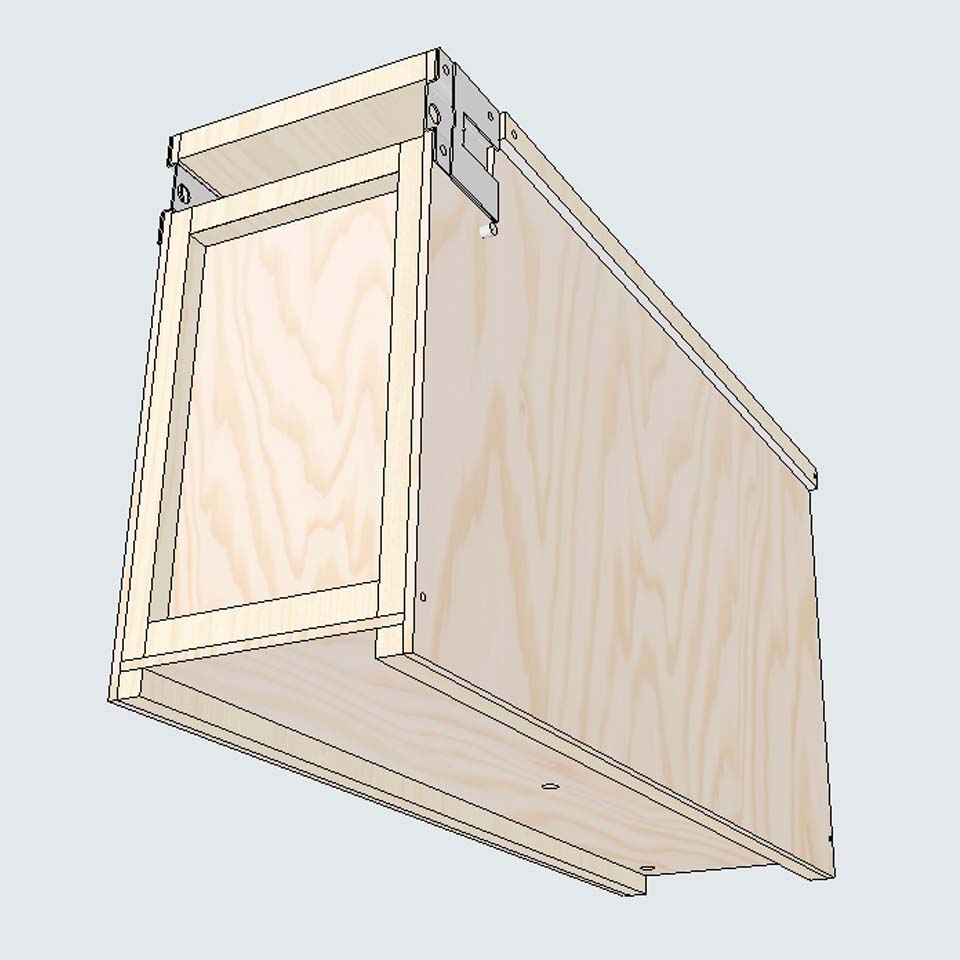

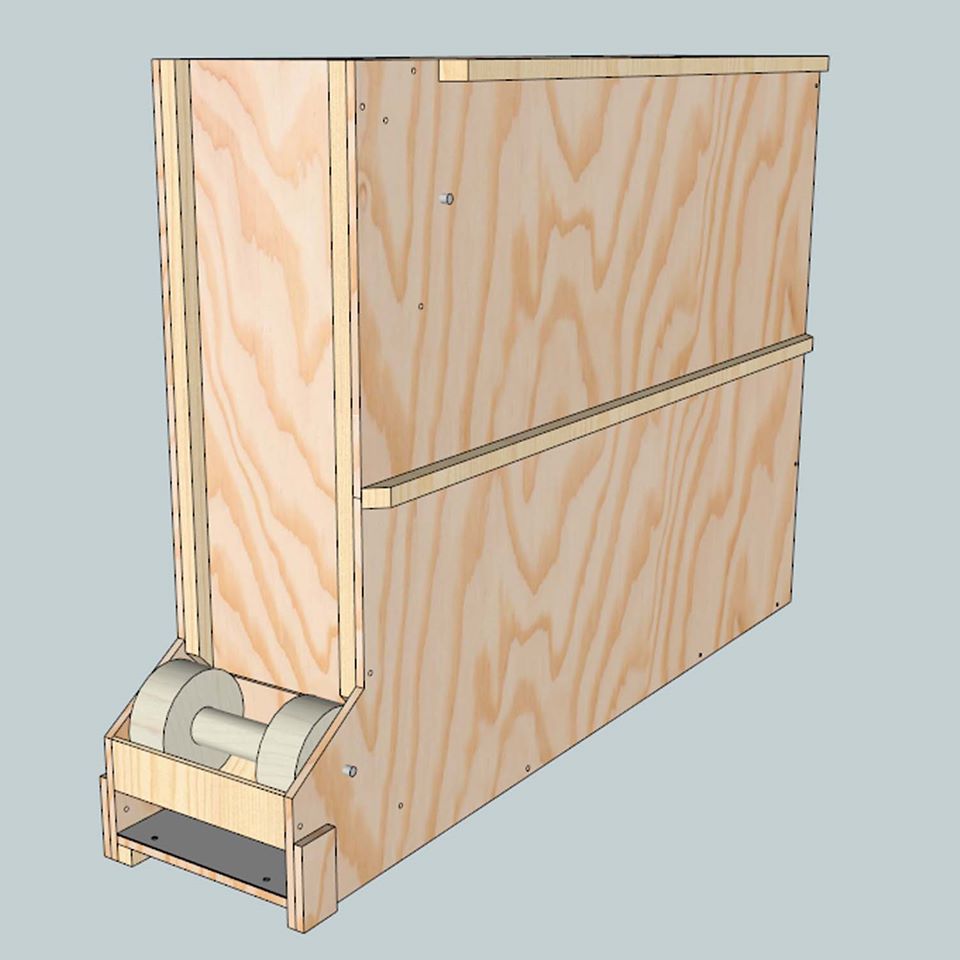

To keep track of everything and help us visualize the blueprints, I have created a series of 3D models. They are shown here for everyone’s viewing pleasure.

There remains the issue of ammunition chutes. To complete these boxes, we need eight ammution feed chutes. They are:

2x 48 inch, Left-Hand Feed

4x 48 inch, Right-Hand Feed

1x 65 inch, Left-Hand Feed

1x 65 inch, Right-Hand Feed

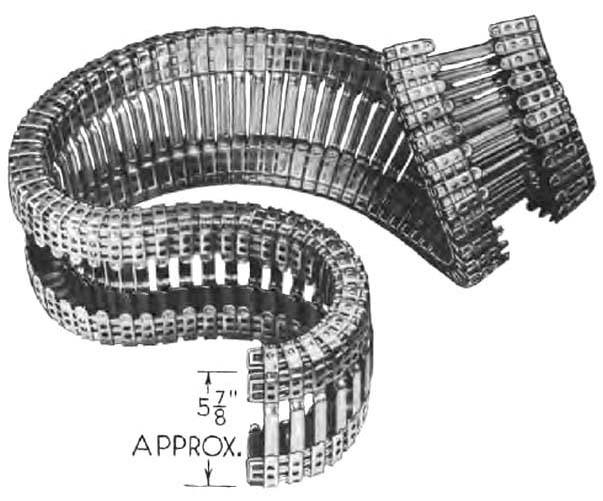

These chutes were linked together like watchbands and could be lengthened and shortened as necessary. The chutes were color coded with bands on each end to identify feed direction – red for left, green for right.

If any of you can help with this it would be greatly appreciated. Ammunition feed chutes used to be quite easy to find, but it seems that finding them has devolved into a game of “who do you know.” While there are some online vendors who regularly carry them, they usually inflate their prices by 50 to 100%. A little help here would go far – especially if the chutes still have their adapter pieces on each end!

A manual illustration for an ammunition feed chute. Wartime feed chutes were made by Smoot-Holman of Inglewood, California (industrial lighting manufacturer, 1922-1972), Brunhoff of Cincinnati, Ohio (advertising display manufacturer, 1890-1954), and Hughes Aircraft of Glendale, California (1932-1997).

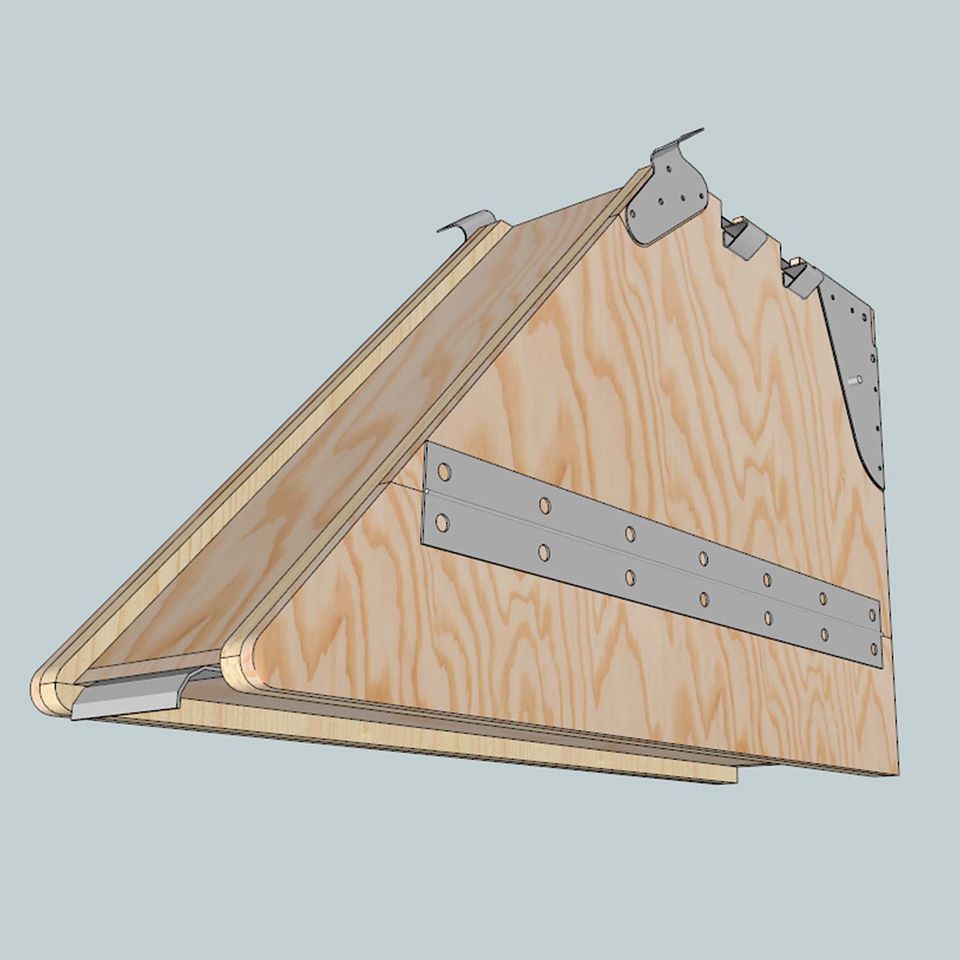

The metal piece which attached the radio ammunition box to the roof was surprisingly complex in its curvature. If anyone has an original of one of these, please let us know.

The radio operator’s ammunition box held 300 rounds of .50 caliber linked cartridges. Tension bands on top of the box could be lifted upward to open the side door for loading and adjusting.

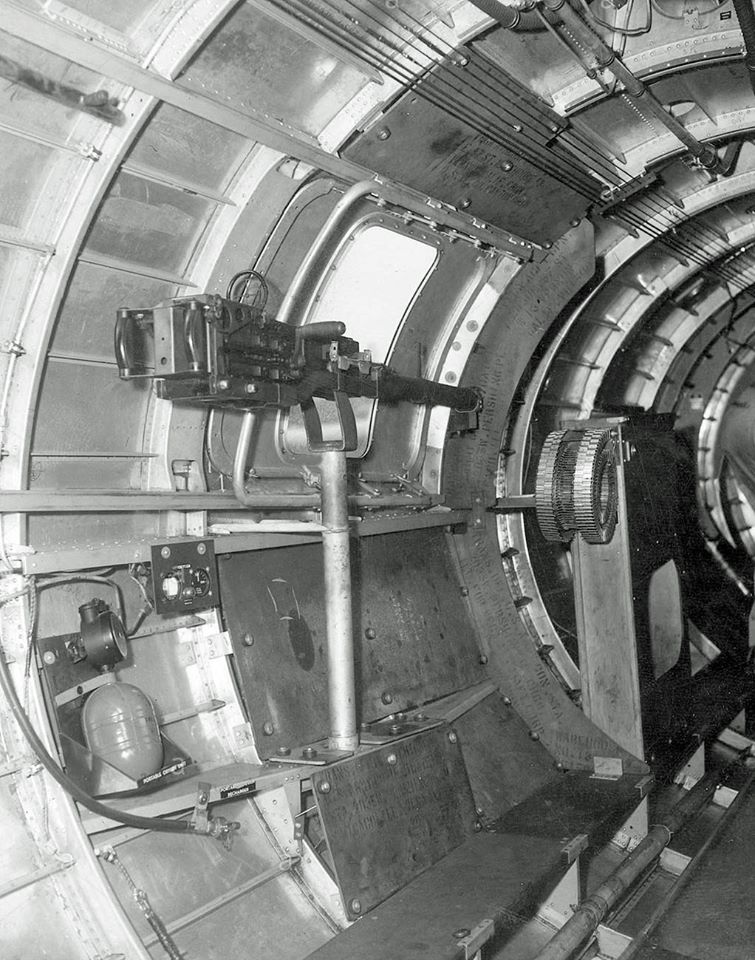

The ammunition fed a single Browning AN-M2 .50 caliber MG mounted in the opened roof hatch. Late F-models and early G-models used the ring mount shown here. The blueprints call for the gun to be held by a Type E-5/E-11 mounting adapter, though photographs often show an E-8/E-12 instead. The gun was fed with a 48 inch, right-hand feed ammunition chute.

The right waist gunner position on a B-17F similar to Lucky Thirteen. Judging by the angled armor plate on the rear side of the window, this F-model is slightly older.

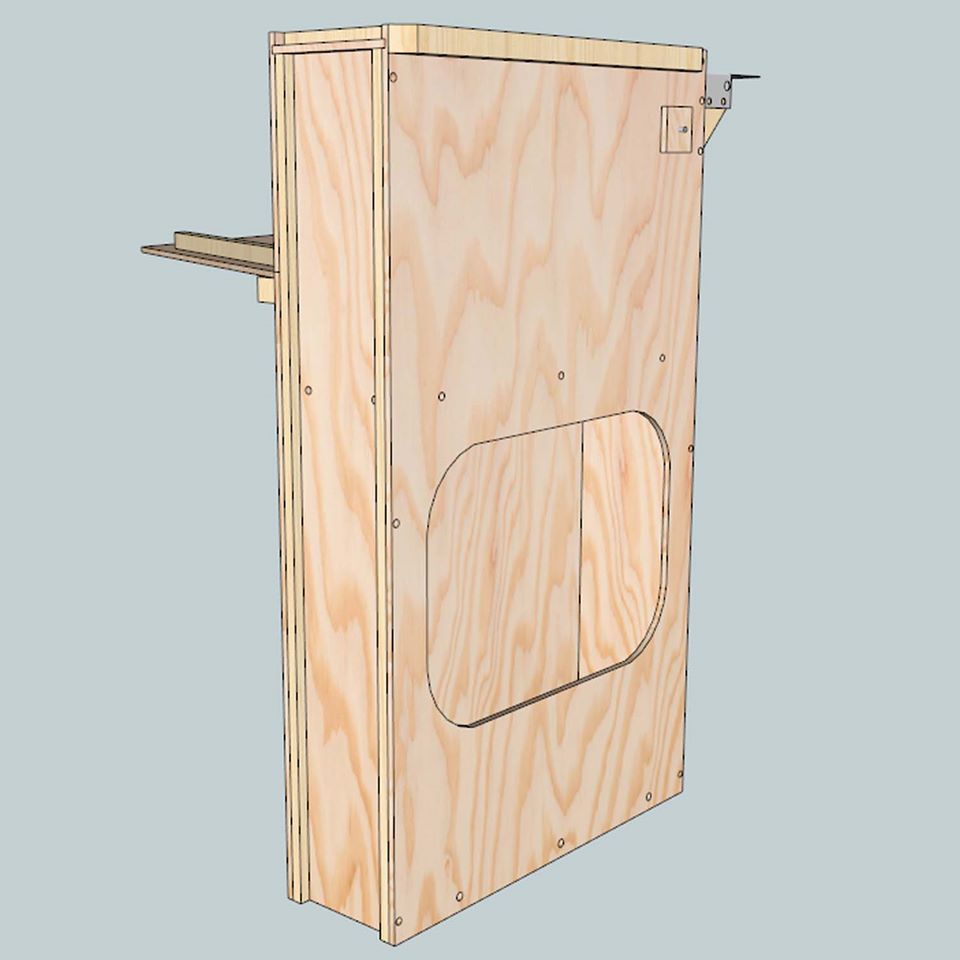

The 3D rendering is of the left waist gunner’s box. The right waist box was a mirror of this design.

The waist gunners’ ammunition boxes each held 300 rounds of .50 caliber linked cartridges. The lids slid out whenever loading and adjusting was necessary. The RC-43 Marker Beacon Receiver sat on the assembly which braced the left waist gunner’s box against the wall.

The ammunition from these boxes each fed a single Browning AN-M2 .50 caliber MG mounted in an opened waist hatch. Each gun sat in an E-8/E-12 adapter which was mounted to a yoke pedestal attached to the aircraft. These guns were fed with 48 inch ammunition chutes, with one having a right-hand feed and the other a left.

1LT Edwin R. Bush peeks out the nose of Royal Flush (42-5132, 91BG). Royal Flush was lost on 22 June 1943 over the North Sea. Bush survived but was killed in an accident over Offutt AFB after the war. Note the insulation that has been stuffed in the bottom of the nose, presumably to cut down on vibration or to keep spent brass from collecting. This practice can be seen in virtually all F-models with nose gun modifications.

As discussed in our article on the navigator’s table, B-17F noses were in a constant state of flux. Lucky Thirteen‘s variant used a pair of slanted cheeks similar in appearance to that used on G-models, though they were mounted on opposite sides. These guns were complemented by a single gun in the nose using a custom mount installed at the Cheyenne Modification Center.

Since these guns were not factory installed, there are no blueprints for their usage. From the photographs and drawings we have seen, it appears that the boxes later used to feed these guns were similar to what was later used on G series cheek guns. Each of the three boxes held 300 rounds of .50 caliber linked cartridges. Likewise, each fed a single Browning AN-M2 .50 caliber MG, held by a Type E-5/E-11 mounting adapter, using a 48 inch feed chute. Two of these were right-hand feeds and one is a left-hand feed.

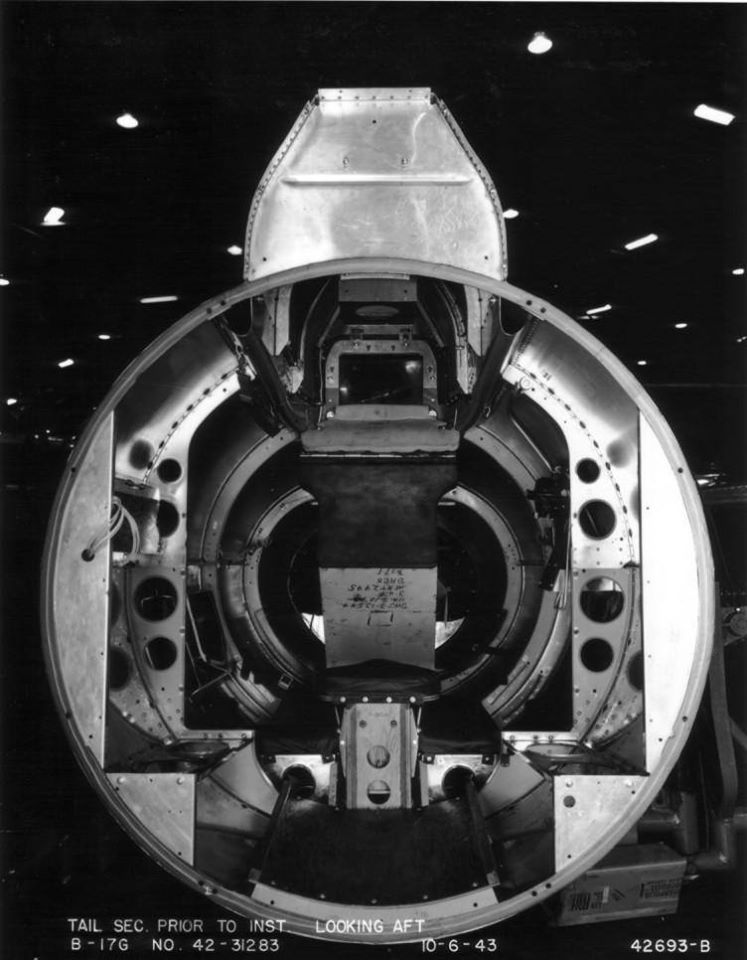

The stinger assembly to 42-31283 – a B-17 which never left the US. While the boxes are not installed in this picture, you can see where they would have gone. Note the seat and armor plating. The gunner sat on his knees with this chest against the armor plate.

The 3D rendering is of the tail gunner’s right side box. The left tail box was a mirror of this design.

Wooden tail boxes were introduced partway through the F series. G boxes are a little different from this design, but are so similar that they can be difficult to distinguish.

The tail gunner’s ammunition boxes held 565 rounds of .50 caliber linked cartridges each. The ammunition from these boxes fed a pair of Browning AN-M2 .50 caliber MGs mounted together on a barbette. Each gun sat in an E-5/E-11 adapter fed with 65 inch ammunition chutes, with one having a right-hand feed and the other a left.