Our followers may recall that we hope to rebuild a Briggs-type A-2 ball turret for Lucky Thirteen. What some of you may not know is that Briggs made a lot more than ball turrets – in fact, they made a good portion of the B-17 itself. Look at any wartime photo of a painted B-17 and you will notice that the paint did not fade evenly. This is because the aircraft was built in subassemblies, and Briggs Manufacturing was a subcontractor for the B-17’s tail, outer wings, bombbay doors, and ball turret.

Walter Briggs started out as an upholsterer for B. F. Everitt, whose company made the jump from carriage components to auto parts, building for early giants Ford and R.E.O. at the turn of the century. When Everitt optioned the autobody division to move on to complete cars, Briggs purchased it, renaming it Briggs Manufacturing in 1909.

Briggs was a major figure in the Detroit area, being a major donor behind the Detroit Zoo and owner of the Detroit Tigers baseball team. In this capacity, he was most famous for his expansion of Tiger Stadium, which until 1960, was formally titled Briggs Stadium.

Prior to the Second World War, most automakers only supplied a running chassis, which would then be fitted with custom bodywork. This could be a mass-produced body (such as the Ford Model A Sedan), a specialized body (such as an ambulance), or a luxury design (such as Briggs’ LeBaron line).

However, the mass expansion of industry during the war brought an end to this practice and Briggs was purchased by Chrysler in 1953, a year after Walter Briggs’s death. Today, only their plumbing division remains in existence, as Briggs found surprising success in 1933 by introducing stamped bathtubs as a lightweight alternative to cast iron.

SSGT Alan E. Magee, ball turret gunner on Snap! Crackle! Pop! (41-24620, 303BG).

MaGree survived a fall of some 21,000 ft without a parachute, crashing through the glass of the St. Nazaire railway station on 3 January 1943. While seriously injured – to the point he was barely recognizable – Magee received medical attention and made a slow recovery, resulting in Magee holding the record for the highest survived freefall until 1972.

Said day’s strike was also noteworthy for two other historic events – it saw the first use of the ‘bombing on the leader’ tactic as well as the first use of predicted anti-aircraft fire (rather than barrage).

A chart showing which components on the Boeing B-17 were manufactured by Briggs.

42-38091, a B-17G which never left the states.

Note the variety of shades at which the OD paint has faded. Left unattended, the dark olive could fade to an almost khaki color.

B-17Gs on the factory floor. Note that the tail and outer wings, which have arrived from Briggs pre-painted.

Also note that these aircraft lack cheek guns – they have not yet been processed through their modification centers.

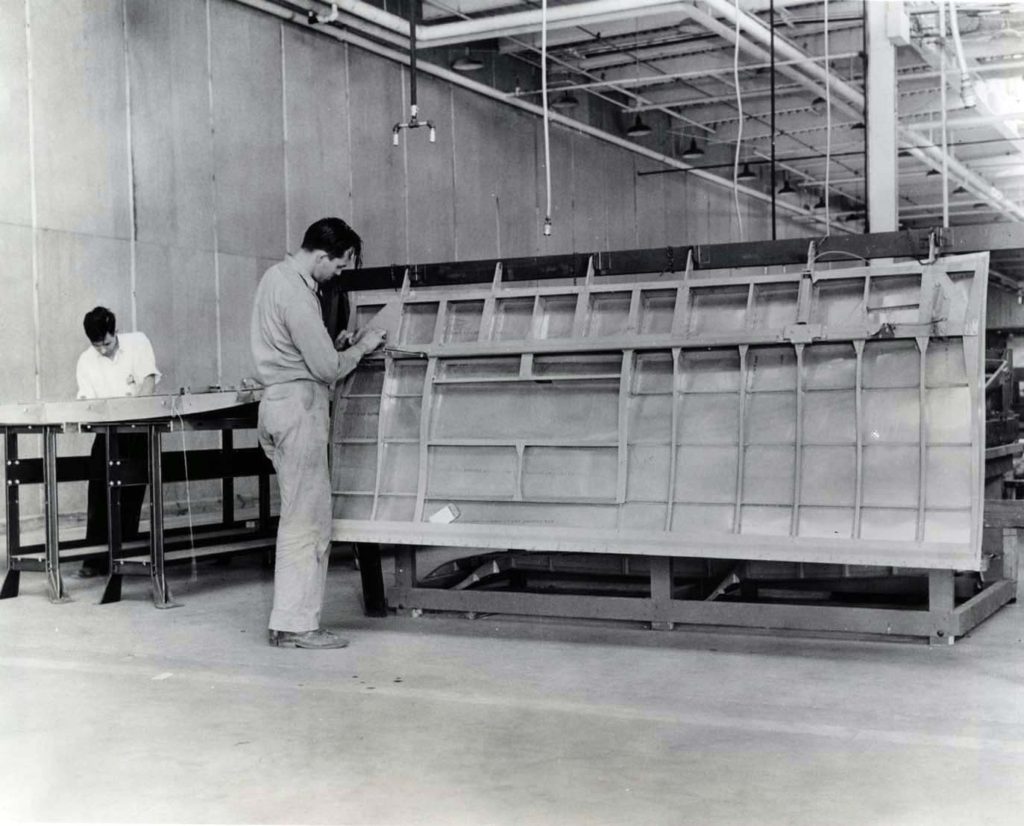

Briggs employees fabricating B-17 bombbay doors.

We have a pair of bombbay doors that need restoration if anyone wants to volunteer!

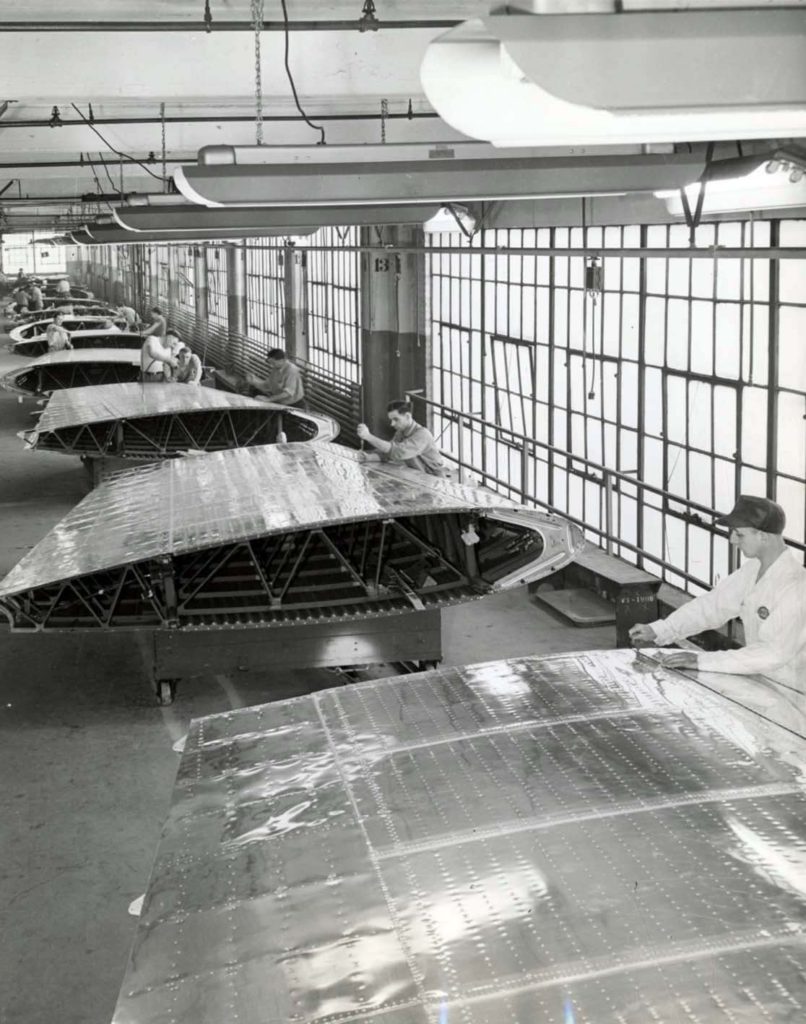

Wing intakes are stamped and assembled at Briggs Manufacturing.

Wings panels which will later cover the B-17’s fuel tanks are riveted at Briggs Manufacturing.

CEO Walter Briggs’s office.

Outer wing panels under construction at Briggs Manufacturing.

B-17 wingtips underway at Briggs Manufacturing.

At the time Chrysler purchased Briggs, the company had some sixteen individual factories, all but two of which were in Detroit.