Recall how we have been trying to fundraise for some turret parts in Europe? Well, we have finally purchased them. As such, I can now tell the whole story.

Shortly after we announced our percentage agreement with the McKowen collection back in January, we were contacted by Nicholas Godfurnon of the Belgian Aviation Preservation Association (BAPA). They purchased a couple pieces, and we began chatting. They have been working hard to rebuild a North American B-25J and, when the discussion came around to gun turrets, I recommended they talk to Fred Bieser. So, I put them in touch. That is when a local named Robert Bodart approached BAPA with a collection of pieces his father pulled from a B-17 wreck during the war. BAPA had no use for these pieces – but we did!

It took some time for us to work out a deal. Mr. Bodart could not speak English and the COVID situation prevented the local museum display he had originally planned on. But most importantly, we had to raise the money. The US federal government is ridiculously slow, and we have been waiting a LONG time for them to file our 501c3 nonprofit status. So instead, we had to depend on the money raised from selling McKowen collection pieces. A hearty thanks to everyone who purchased pieces throughout the last several months!

The B-17 in question was “K-King” (44-6139, 351BG). Lost on 12 September 1944, “K-King” was one of 19 bombers of the 1st Air Division (US 8AF) which failed to return from a strike on the oil refineries of Ruhland and Brux. Too damaged to return to England, “K-King” crash-landed near Villers-lez-Heest, where the crew was safely recovered by Allied forces. She was declared ‘salvaged’ on 14 November 1945, but by that time, locals had already gathered souvenirs.

And we are glad that they did! Amongst the pieces Hangar Thirteen purchased from the Bodart family are a near-mint autopilot gyroscope, a Type G-1 oxygen tank, an AN-M2 .50 caliber gun barrel, rudder pedals, a ball turret fuse box, a chin turret fuse box, and a top turret base assembly. This last piece is particularly important for us, as it is the round base usually found on older B-17s.

Now that the pieces are purchased, they are at BAPA awaiting transport to the US. The idea is to crate these parts together with B-25 turret parts, so that, when they get here, I can take them to Fred. We do not know what the cost of shipping will be, but it is bound to be expensive.

Once everything arrives, we will post more pictures detailing everything within. This is a major step in rebuilding the turrets for Lucky Thirteen.

Special thanks to Robert Bodart for coming to us, and a very special thanks to Nicholas Godfurnon for all of his help – we could not have done this without him!

The Bodart collection from “K-King.”

Note the large gray piece on the cart to the left: that is the main body of the aircraft’s Auxiliary Power Unit (APU). Mr. Bodart’s father heavily modified the unit to provide electrical power for their family home. Because of its weight and alterations, it is staying in Belgium. We suggested that it find its way into a local museum – its story is just too cool!

Photo taken 28 January 2021.

The wreckage of “K-King” (44-6139, 351BG), surrounded by locals.

One of the more popular uses of bomber wrecks was making jewelry from recovered plexiglass.

The strike of 12 September 1943 saw 647 Boeing B-17s and 241 Consolidated B-24s, escorted by 31 Lockheed P-38s, 179 Republic P-47s, and 452 North American P-51s, strike the oil refineries of Ruhland, Brux, Madgeburg, Hemmingstedt, Kiel, and Misburg, Germany. 35 bombers and 12 fighters were lost, with an additional 5 bombers and 2 fighters returning home damaged-beyond-repair.

It is worth putting this day’s strike into context.

Just a week prior, US Strategic Air Forces-Europe (USSTAF) had been released from the six-month long control of Supreme Headquarters (SHAEF). As such, the US Eighth and Fifteenth Air Forces were free to continue their bombing campaign against German oil targets. (Ever short on oil, Germany was heavily dependent on oil imports and oil made from refining coal.) No longer bound to coastal targets, the resumption of deep penetrations resulted in heavy fighter opposition.

Much of these fighter attacks came from Luftwaffe Sturmgruppen (Storm Groups) – abundantly armed and armored FW-190s trained to attack US bombers from behind. These fighters were heavy and slow and required escorts of their own. But they were effective. On 11 September their kill-loss ratio was 57-3 and on 12 September it was 47-13. This number dropped on 13 September to 26-18 and, called before Hitler to explain, CO JG300 Maj Walther Dahl blamed this on the increasing number of US escort fighters. The photo shown here is a Sturmgruppen FW-190 attacking a B-17 from the point-of-view of a US fighter’s gun camera.

Dahl succeeded in persuading Hitler to approve the increased use of jet interceptors. It was too little, too late.

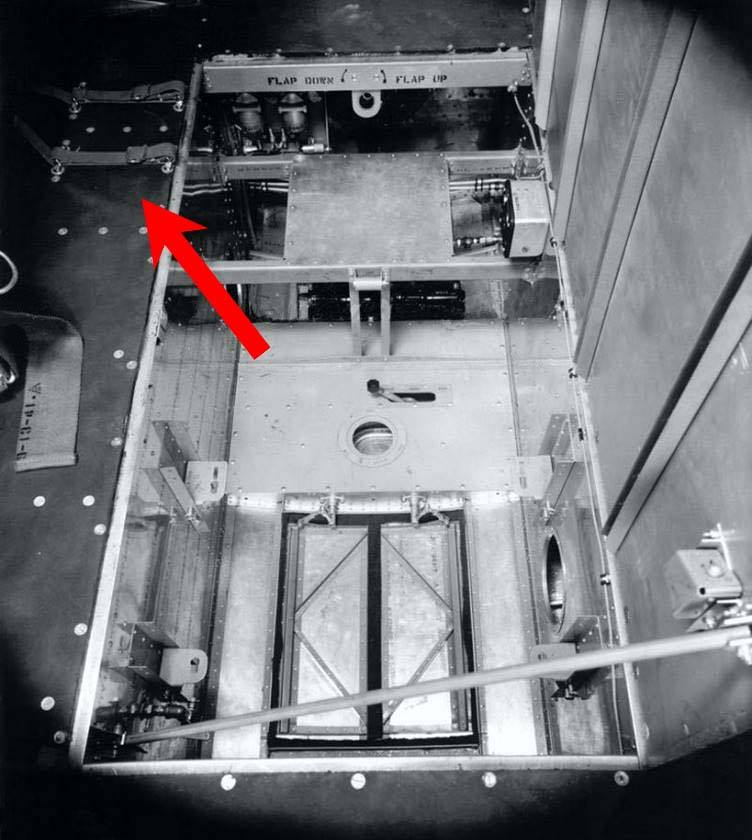

The upper turret base assembly from “K-King.”

Photo taken 28 January 2021.

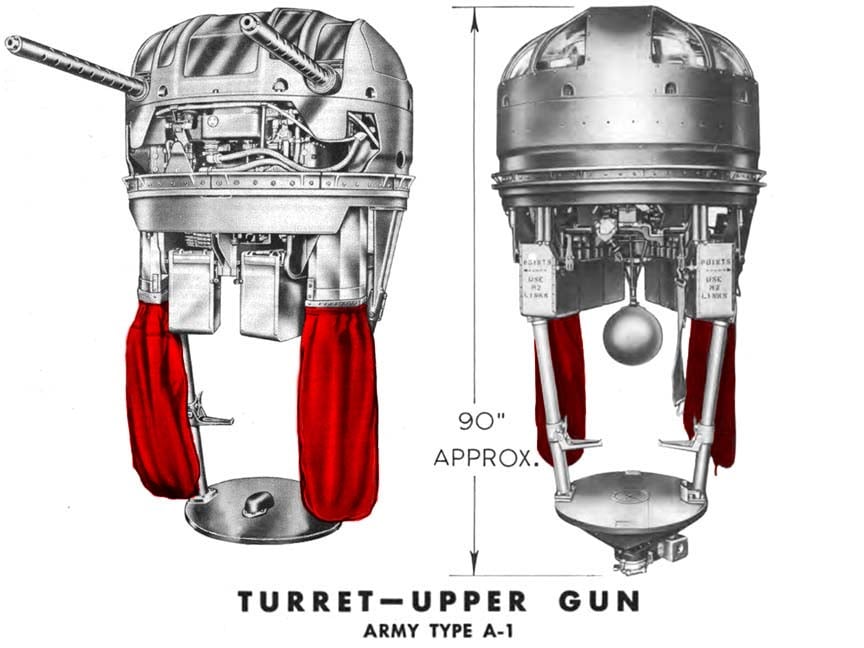

The base assembly for the B-17’s upper turret is highlighted in this manual drawing.

The base came in two variants, a flat one and one with a hump. Hump-type bases were for turrets who’s oxygen was taken from the aircraft’s system, whereas earlier turrets required their own bottle.

Interestingly, these bases are interchangeable, as Sperry Gyroscope (the designer of the turret), designed the turret knowing that it would eventually be altered to use the aircraft’s oxygen supply.

The green box you see here is the main electrical box for the aircraft’s ball turret.

Photo taken 28 January 2021.

The ball turret’s electrical box is highlighted in this manual photo.

As evidenced by the light gray interior, this ball turret was built by Briggs Automotive Manufacturing. The electrical box from “K-King” was built by Emerson Electric , as evidenced by its green paint.

The crew of “K-King.”

A photo of BAPA’s work on their North American B-25J taken in 2018.

Looking good!

Last week was a tough one.

A B-17F cockpit display, consisting of original parts, came up for sale last month. It consisted of pilot seats (with brace assemblies), both control columns (with yokes), the throttle pedestal, and instrument panel. The panel was in rough shape – which was fine, as we are making a new one – but the controls and throttle pedestal were important to us. You see, F model pedestals were unique from G ones, and we are the only project these parts were correct for. Despite our efforts, it went to a collector.

Still, you have to take the bad with the good, and remain thankful to have the opportunity to preserve history in the first place.

So here is some good news to come from last week.

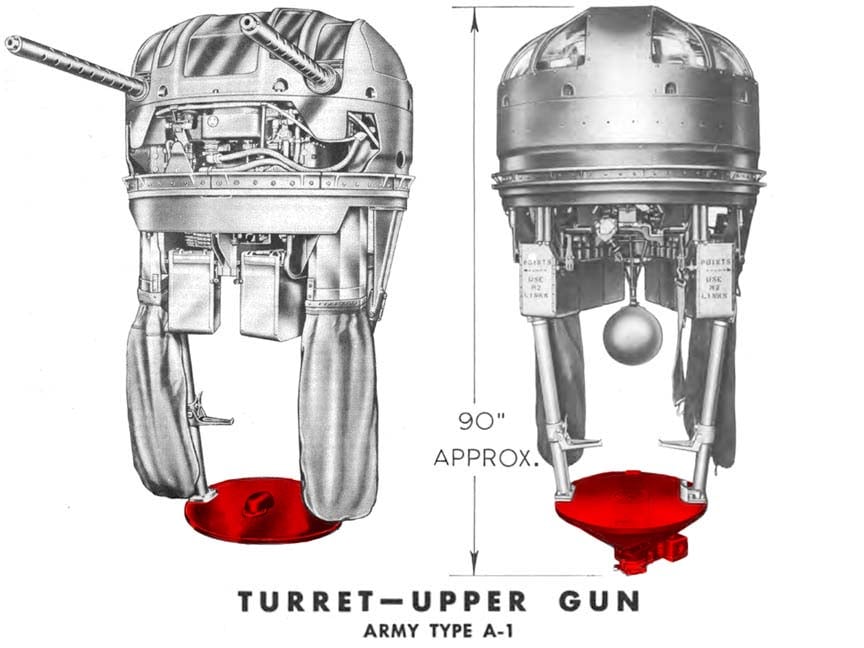

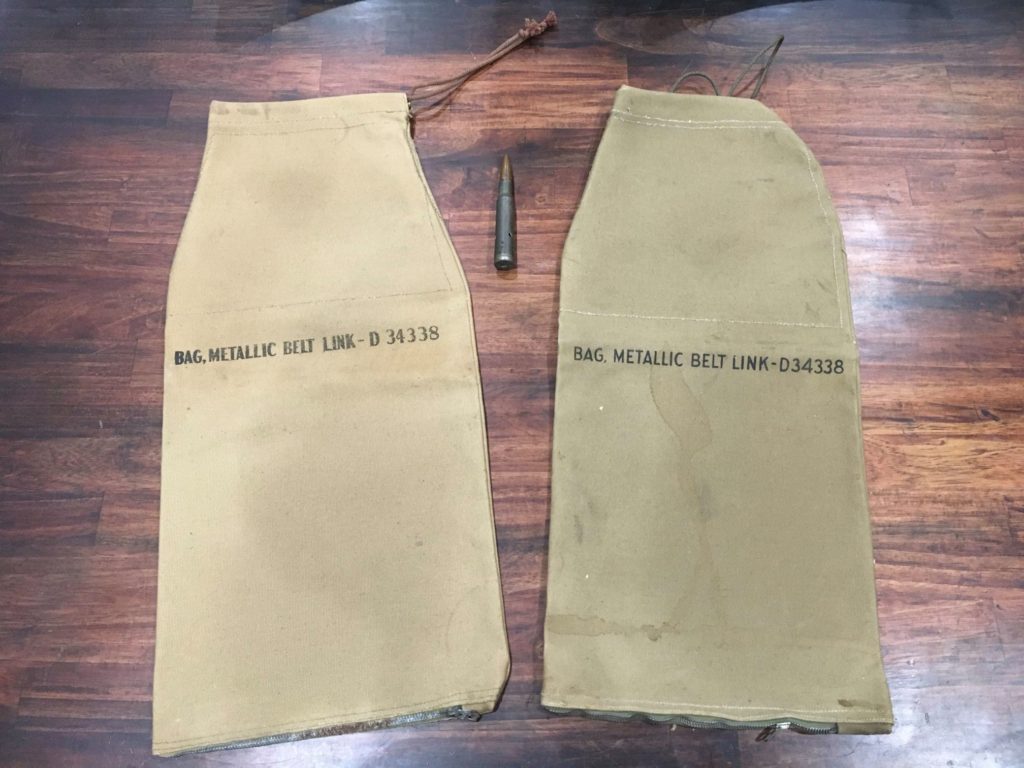

First, is a pair of .50 caliber spent shell bags for our Type A-1 upper turret. These come from Corona, California and are in excellent condition. These bags are quite old as they are the khaki drab color found on early-war US Army equipment. The Type A-1 upper turret carried 798 rounds of .50 caliber ammunition, spread between six steel cans hanging at the gunner’s sides. The gunner himself had a Type A-4 safety belt below him which acted as a sort of sling. If anyone has a Type A-4 sling or upper turret ammo can (among any other parts you might have) and would like to contribute, please let us know!

Second is a pair of Bendix Dual Magneto Switches. These were purchased from Robert Oman of Lake Geneva, Wisconsin. The B-17 went through two different types of magneto switches throughout its service: the Bendix-Scintilla 10-17498/10-17698 and the Briggs & Stratton 85787/85788. Both were interchangeable, with the Bendix switches being standard from the B series up to B-17F 42-30344, after which the Briggs & Stratton switches became standard.

Since Lucky Thirteen was Douglas-built and in service when the switch occurred, either type are accurate for her. We were originally looking for Briggs & Stratton switches, as Bendix-Scintilla switches are easily faked. You see, the blueprints warn that while the Bendix-Scintilla switches are “similar to” their B-5 model, they are not quite the same thing. The B-5 was made for twin-engine aircraft. The tell-tale sign is the markings – Bendix switches made for four-engine aircraft do not have decals; the engine numbers are etched into the metal. We were lucky: not only are these from a four-engine aircraft, they actually have the part number specific to the B-17 stamped on them. These are the real McCoy.

Lastly, in reference to the turret piece in Europe that we were saving up for – we have reached an agreement with the seller. Now to get those pieces over here – and recoup what money we can!

The upper turret shell collection bags, with an inert .50 caliber shell for size comparison.

Photo taken 26 February 2021.

The shell collection bags are highlighted in this manual photo.

Note that the turret on the left has a hump in its base and the one of the right does not. This is because, partway through the A-1 series, the turret’s oxygen feed was changed from an external bottle to a direct connection to the airplane’s oxygen system.

Lucky Thirteen had the bottle-fed Type A-1.

The Bendix-Scintilla dual magneto switches.

The stamped part number in red indicates they were taken out of a B-17.

Photo taken 5 March 2021.

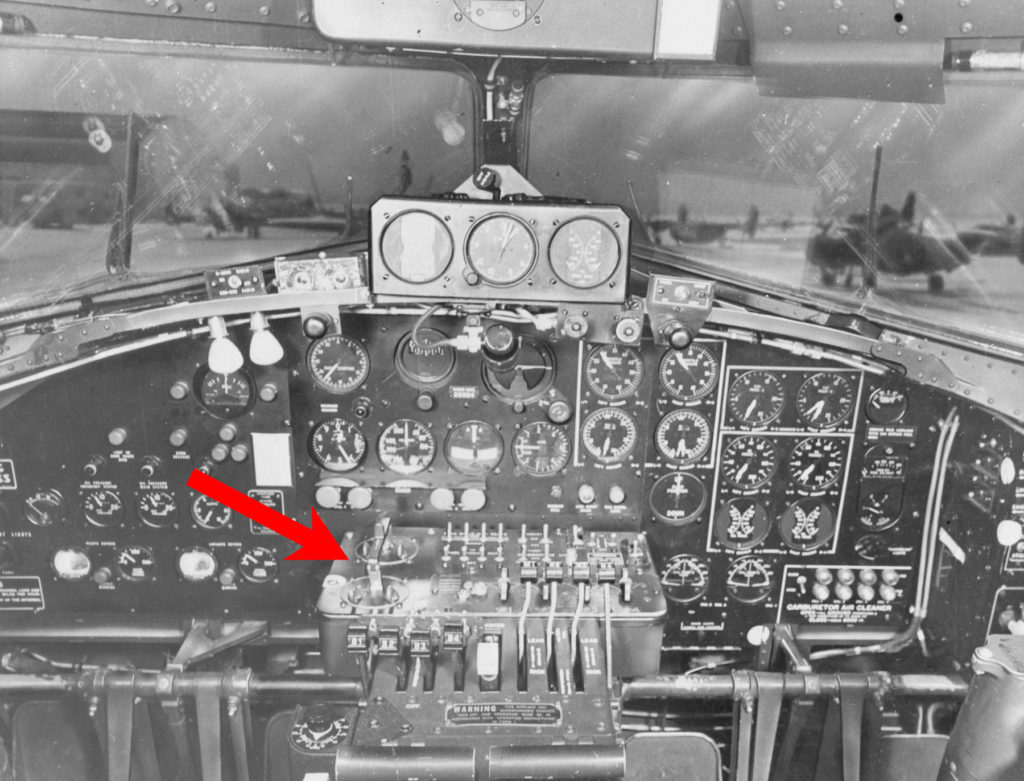

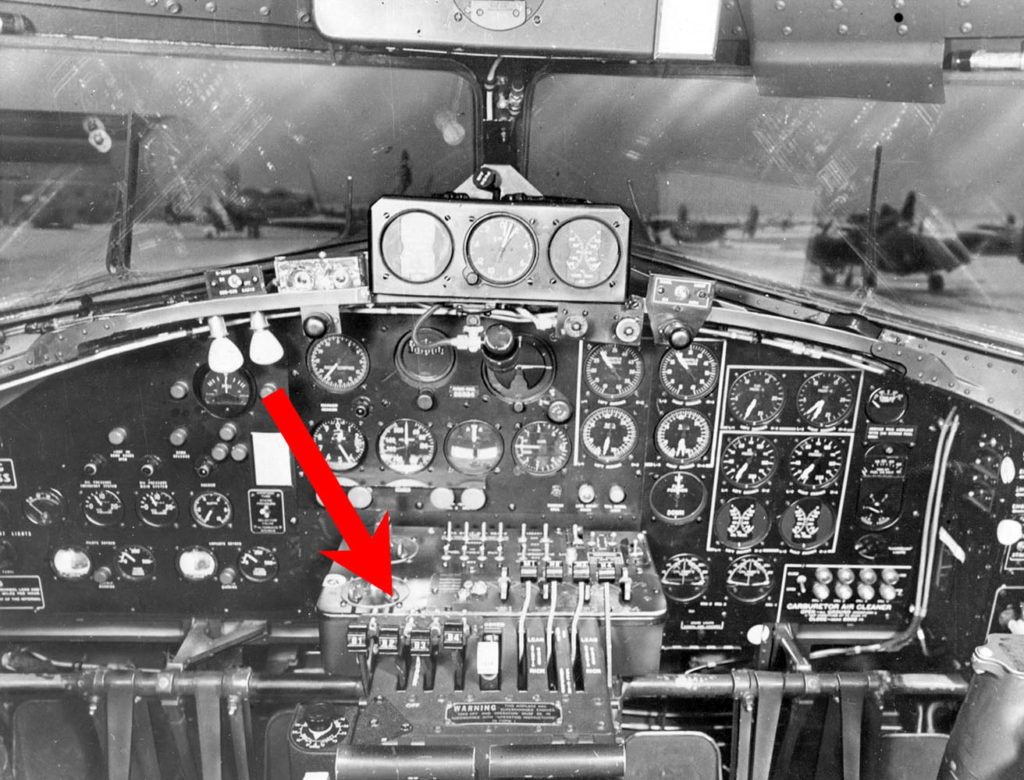

The magneto switches are highlighted in this B-17F cockpit photo. Judging from the layout of the panel, this aircraft is older than Lucky Thirteen. The magneto switches in this aircraft are the Bendix-Scintilla type.

Note the lever above the switches. This was added by Boeing, connecting the main toggle for both switches.

A few recent donations:

The first is a BC-306 which comes to us from Stephen Gerke of Chantilly, Virginia. He donates this piece in memory of his wife’s uncle, SSGT Joe Paolocci, who was wounded-in-action while serving in the China-Burma-India Theatre of the Second World War.

The BC-306 is the antenna tuning unit for the massive SCR-287 Liaison Radio System. We already had an example of this piece, but Stephen’s example was so pristine that we just could not say no. Once we have the system on display and are sure everything works as it should, we will offer the older unit for trade/sell to another project.

Second is a Parker Four-Engine Fuel Primer Assembly sent to us from Albert Stix of St. Louis, Missouri. Albert says he found it in an inventory of equipment taken from old crop dusters out of Chino, California! This is a particularly rare piece and is in excellent condition.

Last is a collection of control fairleads sent to us from Grant Schwartz on behalf of the Yankee Air Museum and their B-17G, Yankee Lady (44-85829). These pieces hold the cables which run from the controls, under the cockpit floor, through the bulkhead, and on to their respective destinations. Due to the awkwardness of this location and the small size of these pieces, I am afraid I do not have a good photograph to use as an example of their installation.

The guys at Yankee Lady also contributed a couple other pieces that will interlock with some pieces due to arrive from England. I think I will wait to share pictures of these for when the English pieces arrive…

Thanks to Stephen, Albert, and Grant for their amazing contributions!

The newly-donated BC-306 Antenna Tuning Unit from Stephen Gerke.

This particular unit is an A model, as evidenced by the pair of insulators on top. Later variants had four.

Photo taken 11 February 2021.

The BC-306 Antenna Tuning Unit is highlighted in this photo of a factory-fresh B-17E.

Note that how, in the B-17, the BC-306 is mounted on its side. Its mount, the FT-142, is attached to a brace, with the weight of the unit being supported by the BC-375’s sway mounts.

Photo taken 16 September 1941.

The newly-donated Parker Four-Engine Primer from Albert Stix.

It still looks new!

Photo taken 19 February 2021.

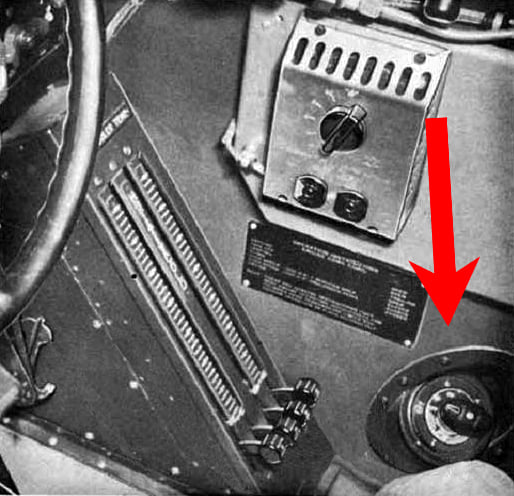

The Parker Four-Engine Primer is highlighted in this photo from the manual.

The primer assembly sat to the right of the co-pilot beside the intercooler controls and manual hydraulic pump.

Note the cowl-flap warning placard – long time followers might remember when we made replicas for Memphis Belle (41-24485, 91BG).

The newly-donated fairleads from Grant Schwartz and the team at Yankee Lady.

Because Lucky Thirteen is an F-model, she has more fairleads than most surviving B-17s, as older B-17s had manual turbochargers.

Photo taken 5 February 2021.

A photo from a B-17F is highlighted to show the manual turbocharger controls.

G-series B-17s replaced these levers with a large washing-machine like electric control.

Judging by the layout of the instruments in this photo, this B-17F is older than Lucky Thirteen.

The turbocharger controls are highlighted in this photo of 1LT Bob M. Welty of the 398BG.

Since rebuilding Lucky Thirteen is going to be a very long project, it has always been our goal to restore and rebuild her systems alongside the bomber rather wait until the airframe was finished. This way, we can ensure that all of her systems are operational and give demonstrations of said systems in operation. Since he came onboard in 2018, Charlie has made incredible progress with the bomber’s radios. With the exception of a couple tuning units, early-style Gibson girl bags, and a MC-163 fairlead clamp, we have every radio component accurate to a late F-model B-17. All that is really left is to find a power source and put them on display. Of course, when it comes time to install these radios, we will need a LOT of lacquered cloth wire…

I digress.

With the radios coming along so well, two other major systems remain for display: the autopilot and powered gun turrets. This hand control represents a major step toward the latter.

Put bluntly, rebuilding turrets for Lucky Thirteen is going to be expensive – each turret will cost something akin to a new Maserati. The B-17F’s turrets were the Sperry-designed Type A-1 upper and Type A-2 lower. Both are almost nonexistent today compared to later G-model variants. In fact, it is easier to locate turret components than it is to locate turret body pieces! This rare Type A-1 upper turret hand control has been in Fred’s collection for a while now, holding it until we saved up enough to purchase it. Thanks to donations and sales from t-shirts and the McKowen collection, we were finally able to pick up this piece last week.

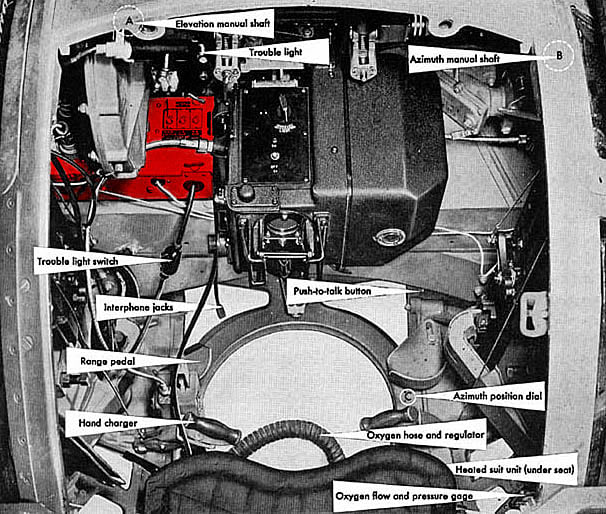

This handle assembly is quite different from later upper turret controls. Safety switches on each of the handles must be squeezed for the turret to move. A thumb roller is connected via tuning cable to the Type K-3 gunsight above. This roller adjusts the reticule on the sight; by matching the reticule to the target’s wingspan, the gunsight can calculate range (amongst other variables). A pair of spring switches function as triggers, firing the guns via electric solenoids.

Also purchased was a ball turret azimuth position dial. Mounted beside the gunner’s right foot, the dial indicated where the turret was pointed in periods of low visibility.

The newly purchased Type A-1 upper turret hand control assembly and Type A-2 lower turret azimuth indicator.

Photo taken 4 February 2021.

A rather blurry manual photo which shows the interior of a Type A-1 upper turret.

Note the Type F-1 oxygen bottle on the swing assembly. This was changed with Emerson turret 1851 and Steel Products turret 1653 to a direct-line fed through the aircraft’s oxygen supply.

A top turret interior pic from Sentimental Journey (44-83514) showing the later style hand control. Rather than a thumb wheel, range is calculated on this hand control using a motorcycle grip on the right side.

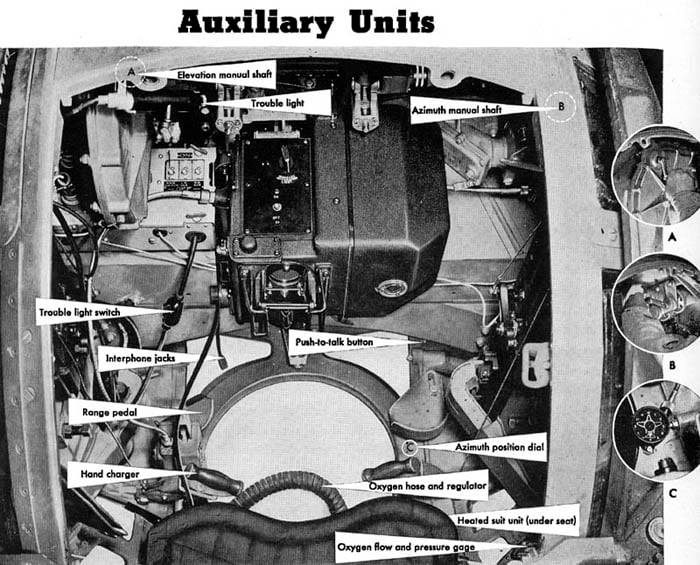

A manual photo showing the various interior components of a Sperry ball turret. The azimuth indicator is visible beside the right pedal. The foot pedals are used to calculate range.

This turret was made by Briggs automotive manufacturing. Ball turrets made by Emerson Electric had green interiors.

Note the dials on the gunsight. Early K-3 and K-4 gunsights had flat panels rather than recessed ones for its switches. We will need flat-panel type gunsights to be accurate.

TSGT Dale W. Rice of the 303BG sits on the base of his top turret. Because of where he is sitting, we cannot tell if this turret is a Type A-1 or Type A-1A. Still, photographs of this area are rare due to how confined this compartment was.

Rice was actually present on the 6 September 1943 mission wherein Lucky Thirteen was shot down, his aircraft, Old Squaw (42-3002), ditching into the North Sea. This photo was taken after his return to active duty on 6 November 1943.

Two items are of interest in this photo. One, note that Rice is wearing an RAF parachute – long preferred over US designs because of its quick release box. Also, note that to the left of the photo is a component to the LORENZ blind-landing system. These were increasingly installed starting in late-1943.

Longtime followers might remember Chris Ely of Branson, MO, who is currently restoring the bomber’s two Type A-2 carbon tetrachloride extinguishers. Chris is good friends with Jo Smith, bladesmith and owner of Silver Anvil Metalcraft. Jo is currently fabricating the control column boots that will go in the cockpit of “Lucky Thirteen.” As an early teaser, when Chris came to help us sort through everything, he brought along another piece by Jo – the straps which help hold the bomber’s strike camera shutter coils, as well as a piece of artwork from his son (who is a big fan).

The newly recreated shutter coil straps made by Jo Smith.

Thanks Chris and Jo!

The shutter coil straps are highlighted in this photo of a B-17E camera bay.

Photo taken 16 September 1941.

Ray sent over a picture on 26 December 2020 for everyone to see. He had spent Christmas working on this:

The hat channel to Station 5 on Lucky Thirteen is now complete.

The Station 5 that Ray is rebuilding is largely original, its original skins visible in the background. Portions of the wingspar and bomb bay control assembly are also visible on the table.

Photo taken 26 December 2020.

As of 23 November 2020 I am happy to announce that Bob Hachmann has been officially added to the Hangar Thirteen website’s team page.

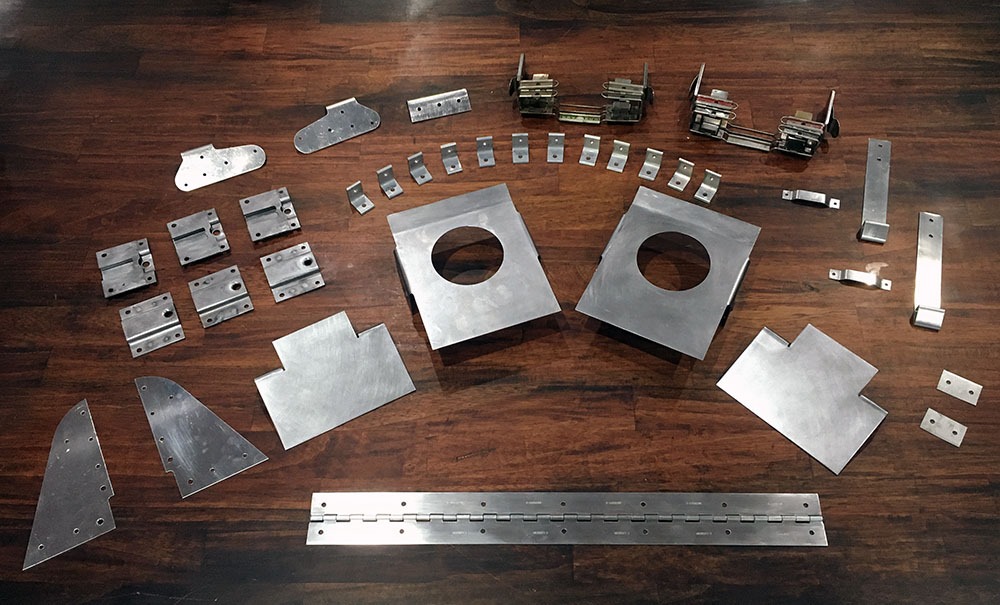

Bob recently completed the metal bits needed to rebuild the ammunition boxes for Lucky Thirteen. In total, Bob fabricated some 33 separate pieces using original Boeing blueprints. With the tail boxes already completed, these bits cover the two waist boxes, the radio box, and the three boxes for the nose compartment. As of this update, the steel pieces are already in Asheville to be plated in silver cad – the finish called for in the blueprints; later the aluminum bits will have to be anodized.

Bob is taking a break for the holiday season but intends his next project to be the box frame for the cockpit instrument panel. Unlike the G-series, which had a wooden frame, the box frame for the F-series was aluminum. Everyone be sure to thank Bob for his amazing work!

In other news, Hangar Thirteen and the National Museum of the US Air Force have been in talks with Huston Textiles of Mather, California about recreating the interior fabric for Memphis Belle and Lucky Thirteen. Huston Textiles has done work recreating historic interior fabrics before (namely, trains) and are confident that they can help us make a perfect recreation. Samples of Bronze Green paint and fabric pulled from Preston’s Pride – perhaps the only B-17 whose interior fabric has never been touched – have been sent to Huston Textiles for review.

This is a big step for both aircraft and, if everything works out, will be of serious aid in the future – in the restoration of B-17D Swoose, (40-3097, 11BG) for example. Now if we can make headway in recreating the insulation…

Bob’s recently finished ammunition box components laid out on the table. The hinge – which is part of the radio room box – was purchased aftermarket as the original remains in production.

The box-end ammunition chute adapters were donated by Michael Pendland of Anderson, South Carolina. They are a left-hand and right-hand feed and were used by Bob to ensure proper attachment to the box clips (far left).

These clips entered service in late-1943, eventually seeing use on all G-series ammunition boxes. Since there are no standard blueprints for the F-series nose and cheek armament, we are using the earliest blueprints from the G-series for these boxes.

Photo taken 16 November 2020

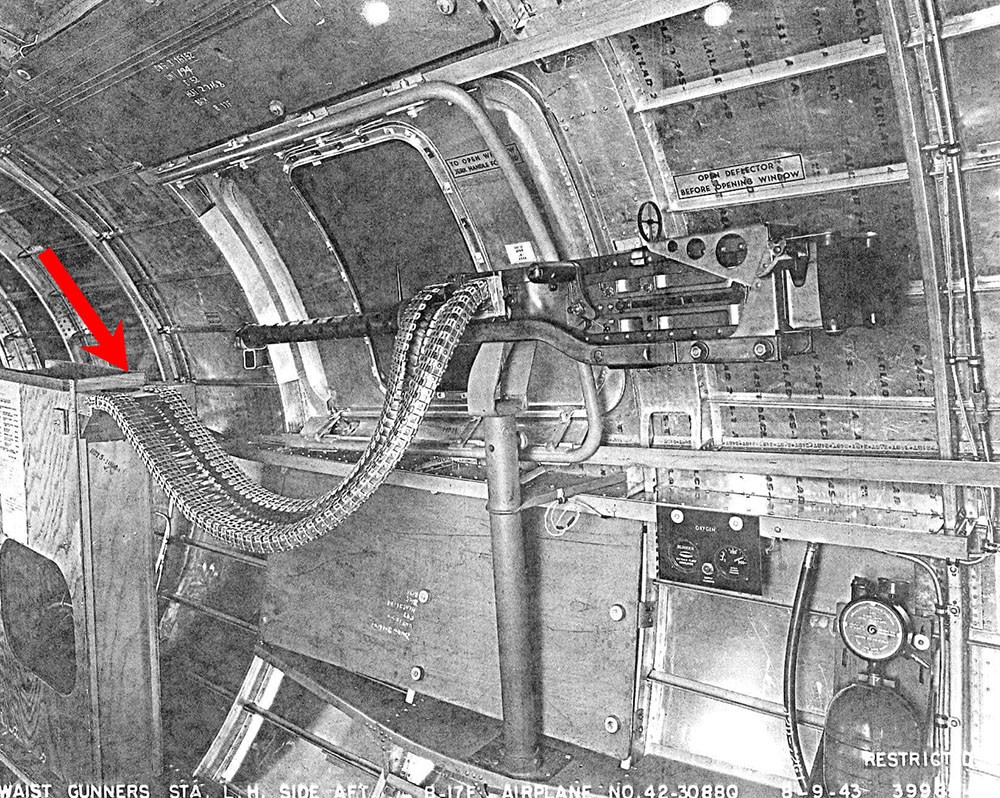

Our one ammunition chute is test-fitted to one of Bob’s waist box pieces.

Photo taken 16 November 2020

The left waist position on 42-30880, a B-17F that never left the states. Note how the chute attaches to the box – Bob’s piece is identical.

Photo taken 9 August 1943.

The Bronze Green paint and interior fabric samples sent to Huston Textiles. A sample was also sent to the National Museum of the US Air Force for reference.

The coloring in this photo is deceiving. In person, the fabric and paint samples appear quite similar.

A color photo showing the interior fabric in wartime.

This piece is incredible – in fact, downright unbelievable.

It is a NOS C-1 Instrument Testing Cart donated by our friend Andy Rivera.

Made by the Service Tool & Engineering Co. of Dayton, OH, this particular cart has the serial 42-2076 and is marked “US Army Air Corps.” The purpose of this cart is right there in the title: it is designed to test gauges and instruments!

This piece is a real time capsule, as not only is everything about it untouched, but it is in showroom condition. Everyone be sure to thank Andy for this amazing piece!

Andy’s newly donated C-1 Instrument Testing Cart sits outside our hangar for some beauty shots. Even the internals bits are spotless!

Photos taken 28 October 2020.

Ground crews do an airspeed check on this rather rough looking B-17F.

Note how the cart has been connected to a pitot tube. F model B-17s used a pair of Kollsman D-2 pitots mounted on the end of long extensions. If you any have any D-2 pitots that you would like to contribute, please let us know!

Photo taken 23 June 1944.