Restoration of the ball turret’s elevation hand drive for Lucky Thirteen is complete!

The elevation hand drive was one of two major gears that attached to the ball turret’s trunnion assembly.

When I say “trunnion” I am referring to the giant, cup-shaped piece which holds the ball itself. Followers might recall that we were able to acquire a trunnion and hanger assembly for the ball turret in August 2024. Slowly but steadily, it is under restoration.

The A-2 Ball on Lucky Thirteen was built by Briggs Manufacturing of Detroit, Michigan. One of two manufacturers of the ball turret, Briggs ball turrets had olive drab hanger/trunnion assemblies and gray interiors. The other manufacturer, Emerson Electric of St. Louis, used a dull dark green color on these areas.

The trunnion assembly we acquired was Briggs produced, and inspection of the various pieces found that Briggs was inconsistent in their use of primer. Some pieces were painted without any primer at all, while some others used red oxide – a primer generally reserved for steel components, despite the ball using aluminum. Surprisingly, no zinc chromate primer has been found on any trunnion component.

The elevation hand drive was used to rotate the elevation of the ball from outside the turret. In order to enter the ball, the turret had to be rotated to face downward, with the turret turned rearward when not in use.

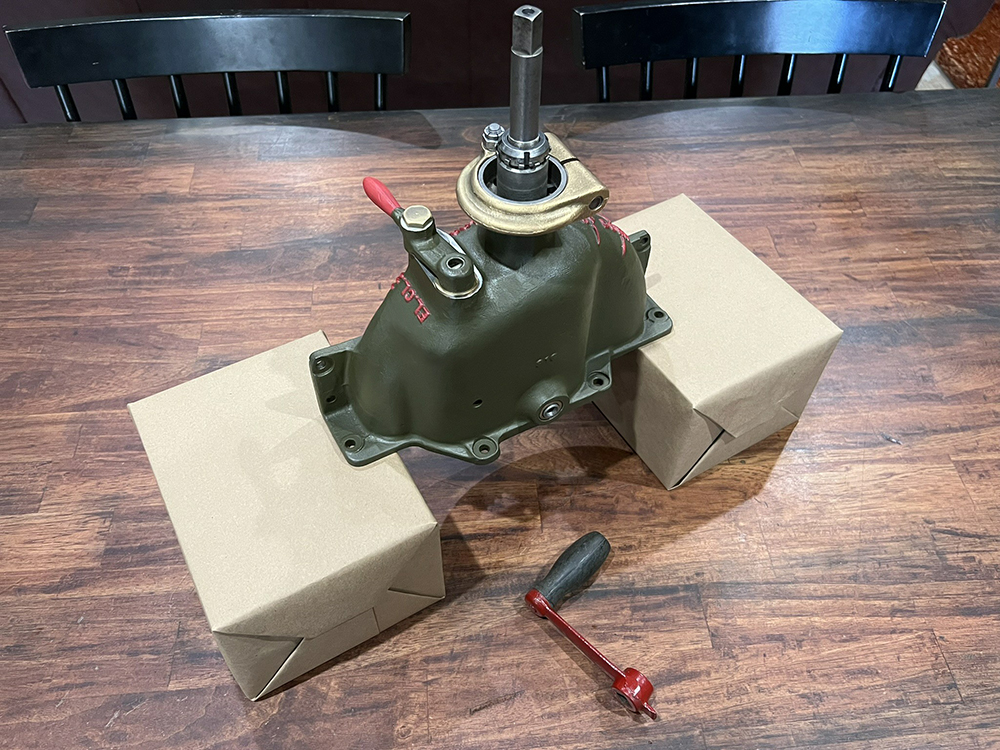

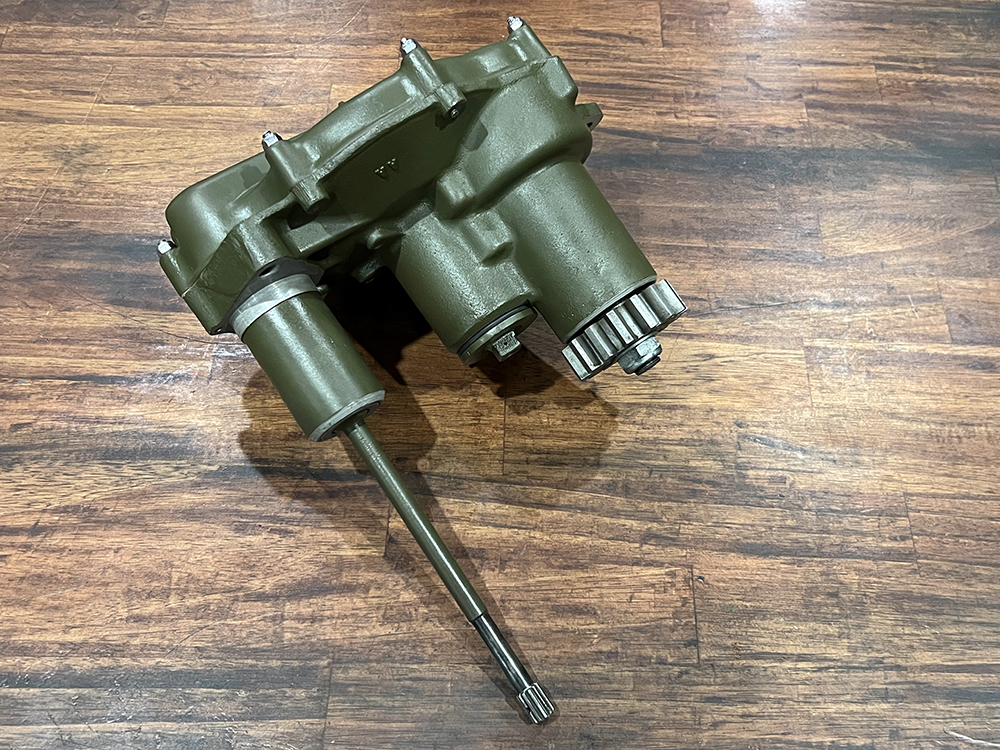

The fully restored elevation hand drive for Lucky Thirteen‘s ball turret.

Photos taken 22 February 2025.

A rare color photo showing the exterior of a Briggs-made ball turret.

Note the olive drab coloring of the trunnion and hanger assembly, as well as the red operating handles and lettering on the elevation hand drive (left).

Something to look for when viewing wartime footage and photographs –

If the ball is facing downward like this, the gunner is likely entering or exiting his turret.

The aircraft in this photo, “Baker-889” (398BG), was lost over Mannheim on 20 January 1945, killing two.

SSGT Harry J. Brody leans out the A-2 ball turret on Hell’s Angels (41-24577, 303BG).

Note the gear on the upper left side of the ball – this is the gear which the elevation hand drive connects with.

Brody became an aerial gunnery instructor after Hell’s Angel‘s war bond tour and, after the war, purchased a ranch in Montana. He was killed in an auto accident in 1957 at the age of 39.

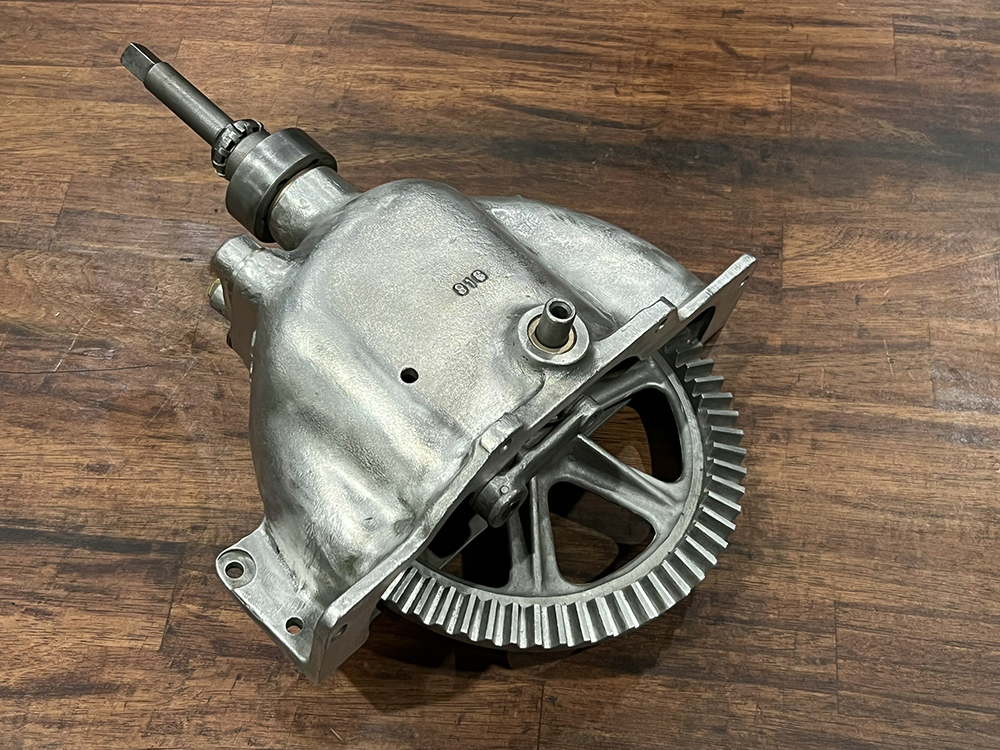

The elevation hand drive is stripped of its postwar repaint and cleaned.

Photo taken 18 February 2025.

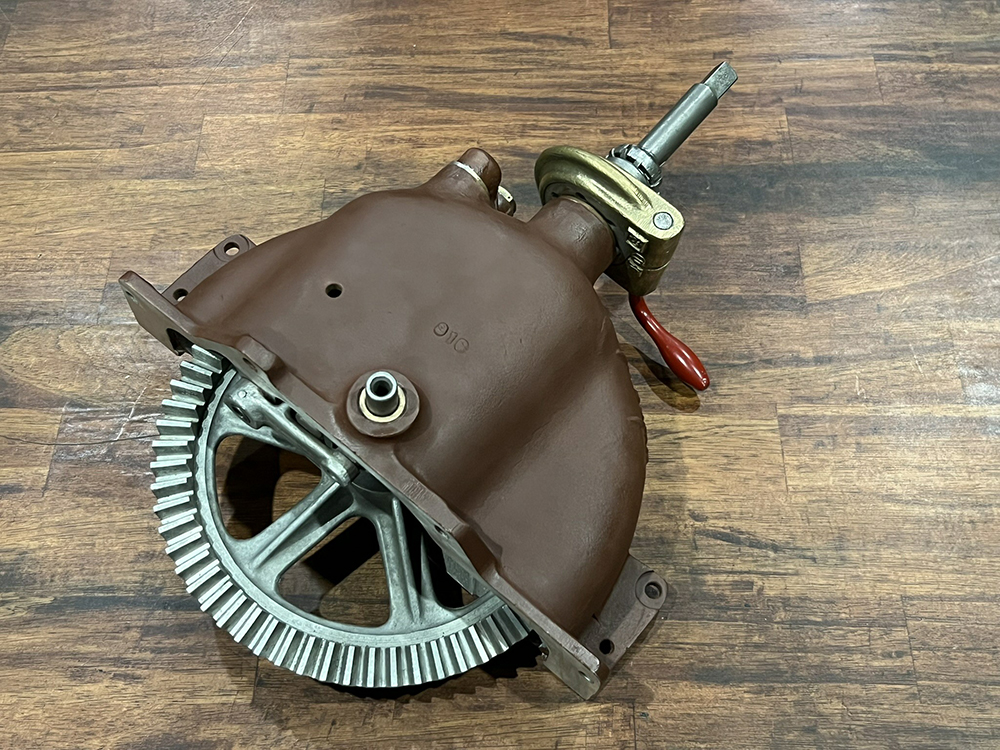

The elevation hand drive is primed in preparation for its final coat.

While red oxide primer is normally used on steel, we found original traces of it on the ball’s trunnion assembly, which was made of cast aluminum. Perhaps this was a means of expedience by Briggs, or perhaps it was standard practice for them – who knows? Rather than assume, we decided to follow the physical evidence we had and mimic this practice on the trunnion as a whole.

Photos taken 19 February 2025.

The brass assembly at the top is the elevation hand drive’s brake. Tightening the red handle prevents the turret from rotating up and down.

The handle at the bottom is normally stowed in a clip on the side of the trunnion. Attaching it to the spindle at the top of the drive and turning it rotates the ball’s elevation.

The red on the brake and crank handles is wartime original and was left untouched, as they were in such good condition.

Photo taken 22 February 2025.

The lever on this side of the elevation hand drive is a clutch assembly. This engages/disengages the drive’s main gear from its companion gearing on the ball.

Surprisingly, this clutch mechanism was not present on the A-2A, only being found on the A-2 and A-13A. (We do not know about the A-13, but based on other components, it likely lost its clutch partway through production.) It was an unusual design choice to remove this piece, though clearly wiser heads prevailed and brought it back at the end of the war. Special thanks to volunteer Howard Lawson for catching this easily overlooked bit of research.

Photo taken 22 February 2025.

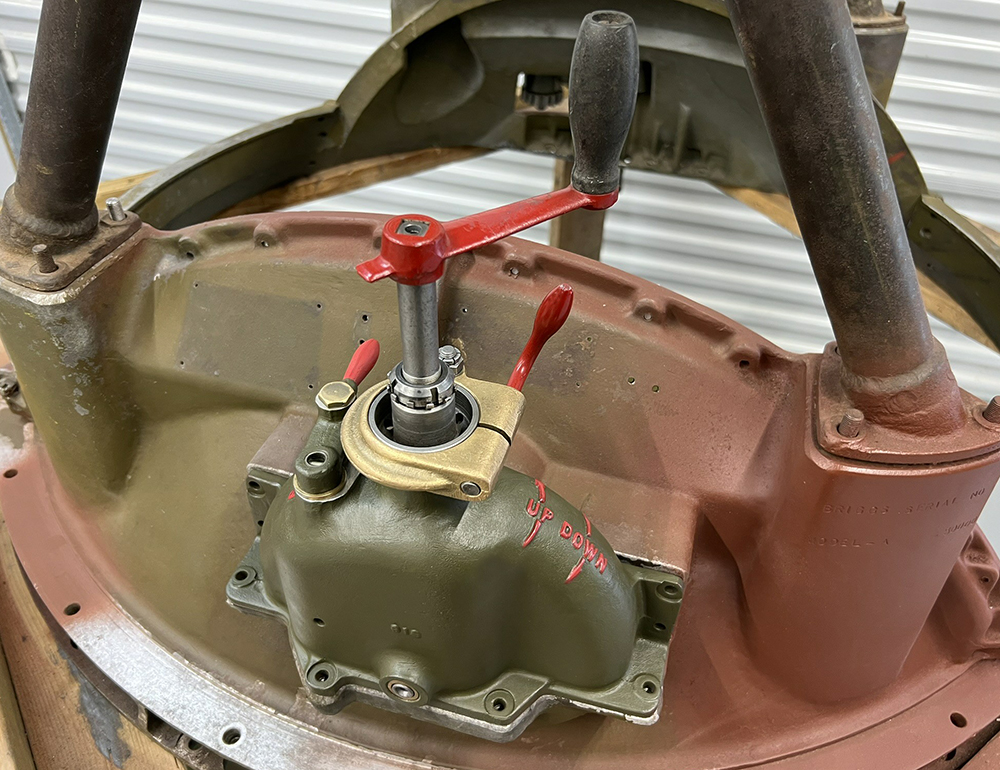

The elevation hand drive, sitting in its future home on Lucky Thirteen‘s ball turret trunnion.

The next step will be to refinish the trunnion. The hanger assembly is missing a leg and will require a talented welder to replace. Outside of that, it is also ready for refinishing.

Photo taken 22 February 2025.

Restoration of the ball turret’s azimuth pinion gear for Lucky Thirteen is complete!

The pinion gear is what connects the motor assembly inside the ball, through the trunnion, to the ring gear mounted inside the airplane. The last of a series of gears, this is the final piece – and the only external one – responsible for the rotation of the ball.

The original paint on the azimuth pinion gear flaked horribly because of a lack of primer, so we decided to use a primer to strengthen the paint.

The colors were painstakingly matched and the assembly cleaned and refinished over the past couple weeks. The interior, I am happy to say, was pristine and needed no work whatsoever. The entire assembly spins as it should without any issue.

Hope everyone likes how it turned out!

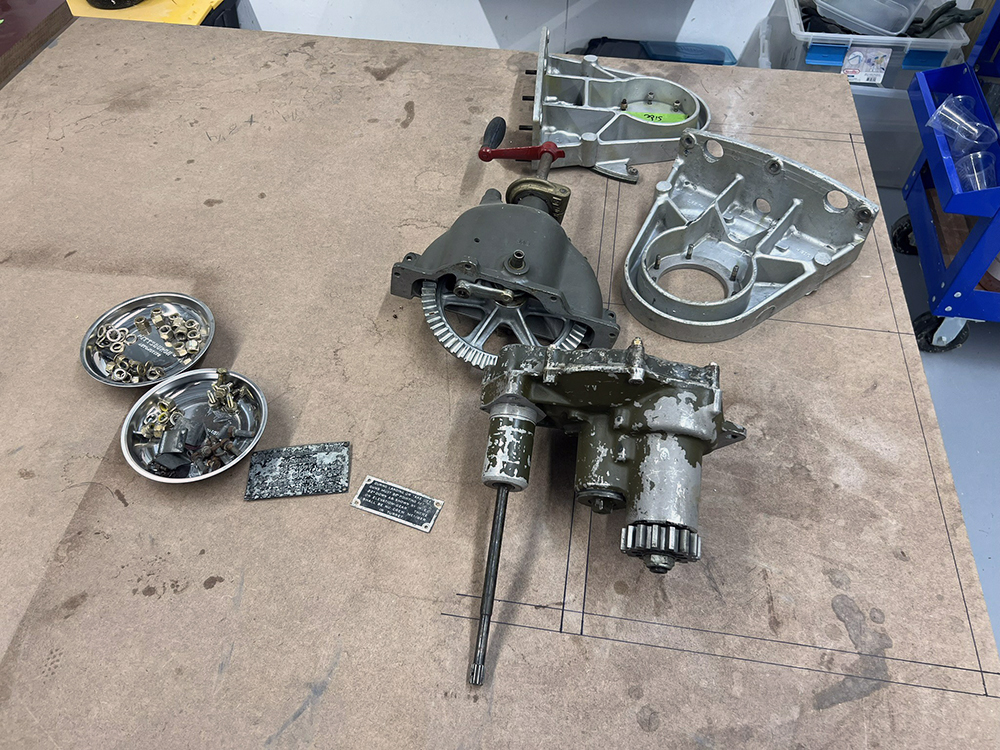

The newly restored azimuth pinion gear for the ball turret on Lucky Thirteen.

Photo taken 12 February 2025.

The pin on the left connects the azimuth assembly inside the ball to the azimuth gear mounted inside the airplane. The large gear on the right is what spins the entire turret.

Photo taken 12 February 2025.

TSGT Everett A. Dasher (303BG) poses with a Type A-2 Ball Turret while on a war bond tour of the United States. The azimuth pinion gear is visible on the upper right.

On 19 May 1943, a round from a Ju-88 deflected off of Asher’s parachute buckle and lodged itself into his spine. Asher lived with this hunk of metal for the rest of his life, passing away at age 85 in 2004.

The azimuth pinion gear is removed from the ball turret trunnion and hanger assembly.

For fun, the turret’s F-1 Oxygen Bottle has been zip-tied in place until the proper brackets can be fabricated.

Photo taken 8 January 2025.

The azimuth pinion gear (center) along with the elevation hand crank and ring support brackets, prior to restoration. Note how the paint barely held onto the pinion gear. The hardware in our example was inaccurate and required replacement.

Photo taken 8 January 2025.

The azimuth pinion gear after being cleaned of its flaking paint. Very little effort was needed to reach this state.

Photo taken 10 February 2025.

The azimuth pinion gear body is primed after the lid assembly is finished.

The brass piece is a plug for inserting grease.

Photo taken 10 February 2025.

The azimuth pinion gear body after receiving its final coat of olive drab. Great care was made to paint and assemble the components individually so that no aspect was rushed.

Photo taken 11 February 2025.

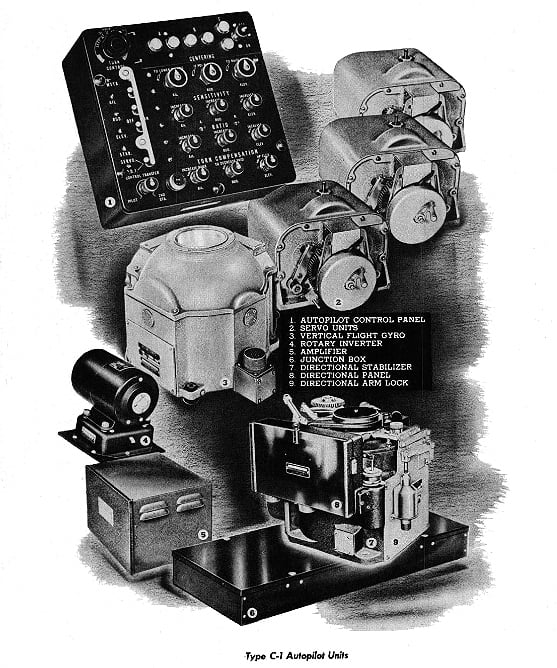

Aside from the turrets, one of the more ambitious projects for Lucky Thirteen is the restoration of her Type C-1 Autopilot System.

Made by Minneapolis Honeywell, the C-1 autopilot was one of the war’s technological marvels, being intimately associated with the Norden bombsight to the point that their components are sometimes mistaken as being one and the same.

In general, a control panel in the cockpit activated a gyro located in the crawlway near the entry hatch. This gyro fed information to an amplifier box which, in turn, fed information to three servos scattered about the airplane. The aircraft’s control cables ran through these servos – one for pitch, roll, and yaw – and, when active, kept the airplane in level flight. The rudder and elevator servos were located on a shelf above the tail wheel, while the aileron servo was in the crawlway beside the autopilot’s amplifier, vertical gyro, junction box, and power inverter. The final component was the directional stabilizer. This was an additional gyro tied to the Norden bombsight above. Whatever the sight aimed at, the stabilizer served to turn the airplane in that direction.

We have been fortunate so far in that we have been able to acquire most of the system’s major components. However, the inverters in our possession were in rough shape. Joe McKowen of Gaffney, South Carolina had donated a set of three: one Westinghouse Electric model and two Eicor models. We were quite taken with the Westinghouse model and wanted to use it if possible.

To our rescue came longtime supporter Victoria Meier of Anthem, Arizona who, along with John Castorina, offered to restore the Westinghouse inverter for Lucky Thirteen. They did an incredible job! Not only did they refinish the unit, but they also took the time to ensure that it still runs properly.

Now that this piece is ready to go, the only remaining pieces are the junction box (which is currently being fabricated Hangar Thirteen supporters) and directional stabilizer. We managed to acquire a partial stabilizer back in 2021, with the hopes that we could replace the missing components. This proved overly optimistic and we have since kept an eye out for a complete example. The only issue is that they tend to be pricey due to collectors who refuse to display their Norden bombsights without one. One will come our way some day!

In the meantime, we are just psyched at how nice our inverter turned out.

The newly restored Westinghouse Electric autopilot inverter.

Photo taken 8 February 2025.

The autopilot inverters donated by Joe McKowen.

The Westinghouse Electric inverter is on the left and the two Eicor units are on the right. Eicor was purchased by Indiana General Corp. in 1962 and dissolved shortly thereafter.

Photo taken 17 April 2021.

A manual illustration showing all the components to the Type C-1 autopilot system.

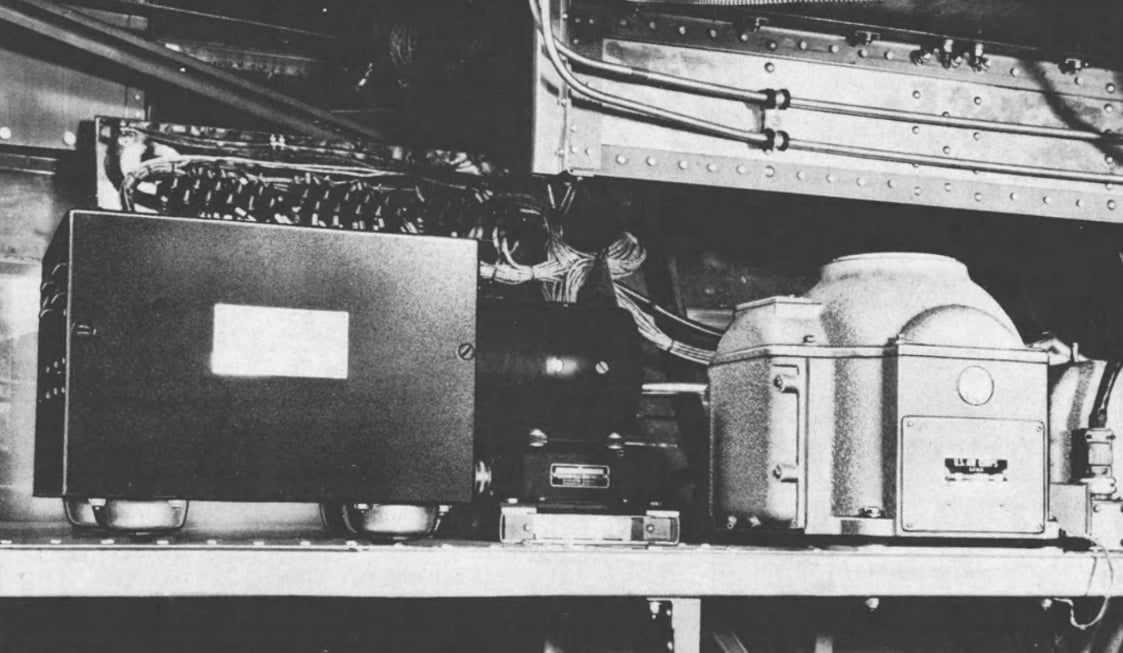

Under the cockpit floor sits (from left to right) the autopilot amplifier, inverter, and gyroscope. The junction box is on the back wall, uncovered.

The aileron servo is not visible here but was located to the left of the camera.

The inverter in this illustration is an Eicor type.

The layout of this equipment varied somewhat depending on whether the aircraft had engine fire extinguishers installed. Most B-17Fs did not have engine extinguishers.

Manual image of a C-1 autopilot’s directional stabilizer.

If anyone has one of these and would be willing to help the project, please let us know!

Another recent arrival allows us to check off the aircraft’s hand cranks.

The Boeing B-17 carried a pair of hand cranks on Sta. 6 (the back wall of the radio compartment) as standard equipment. If there was an electrical failure, these cranks could be used as a backup for the engine starters, landing gear, flaps, and bomb bay doors.

Because of movies like Tora, Tora, Tora (1970) and Memphis Belle (1990), the landing gear crank sockets are fairly well known. These were located on the back side of Sta. 4 (the front wall of the bomb bay). The crank socket for the bomb bay doors was located on the step at the front of the bay’s catwalk. The socket for the tail gear was located on Station 7, at the back of the waist compartment. The socket for the flaps was located under the radio compartment floor, at the front of the strike camera pit. The sockets for the starters were located under each engine.

To aid in reach and leverage, a pair of extensions were provided for the cranks: a larger one for the starters, just over two feet in length, and a smaller, six inch one for the flaps and bomb bay doors.

Interestingly, the hand crank layout changed with the B-17 variant. Up until block F-110-BO, both hand cranks were the single-hand variety. From then onto G-15-BO, one was a single and the other a double. All subsequent B-17Gs carried two double hand cranks.

Double hand cranks are somewhat more readily available today than singles, but we needed two singles to be accurate for Lucky Thirteen.

Now that we have two single hand cranks, all that remains for this component are the two extensions. If anyone is interested and willing, the blueprints for these two pieces are located here and here.

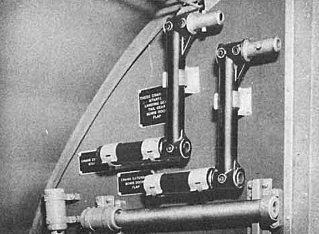

The hand cranks for Lucky Thirteen.

The cranks are laid out in a manner akin to how they were stowed on the Sta. 6 bulkhead.

While we recreated the artwork for the placards, they were engraved by Sean Berry of Lino Lakes, Minnesota. Sean has really stepped up in helping and has done some amazing work.

Photo taken 1 February 2025.

Manual illustration of the hand cranks as stowed aboard a B-17.

The layout shown here is identical to that on Lucky Thirteen.

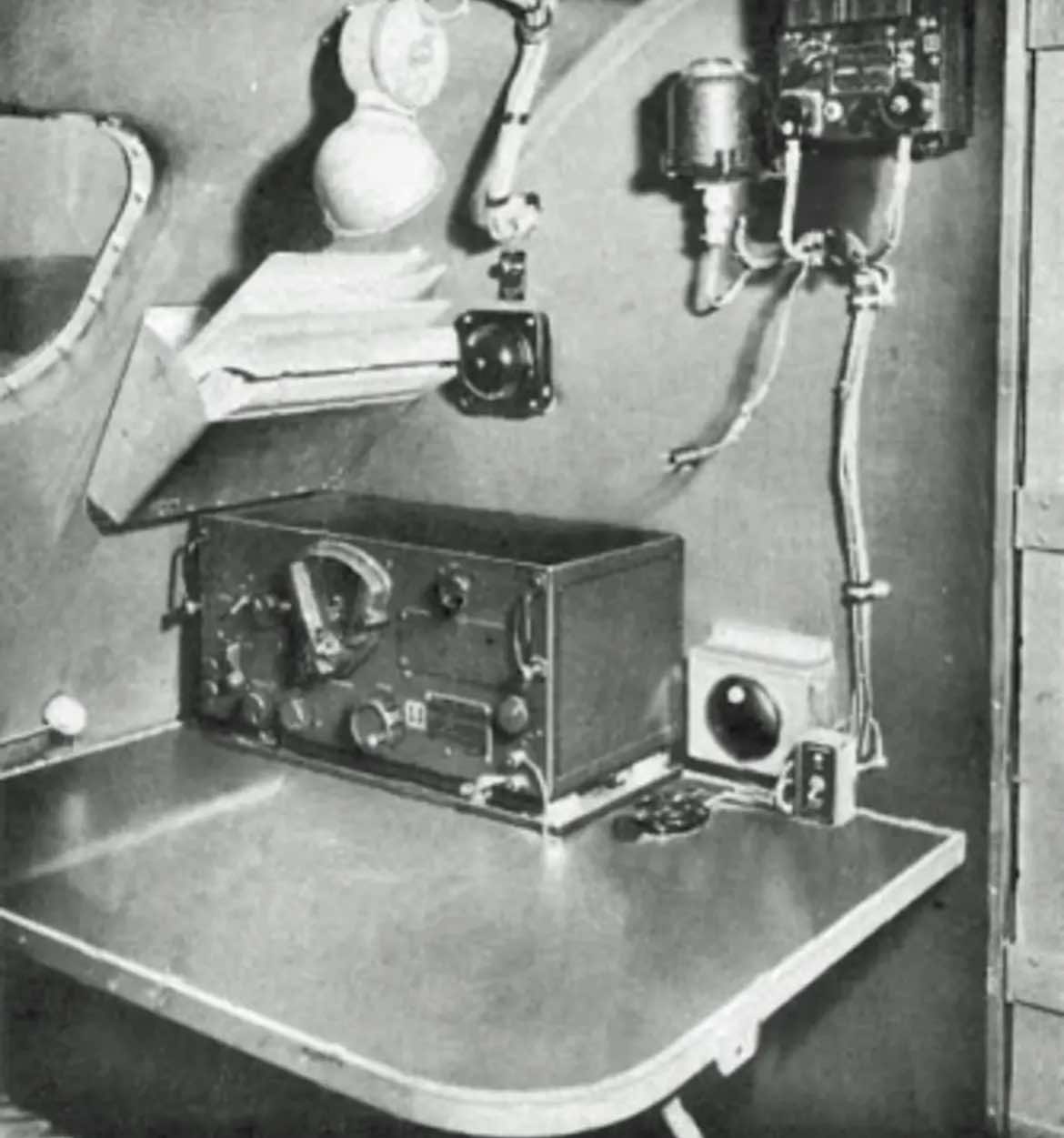

Speaking of Sean, here is another placard he engraved for us – this is the master switch for the BC-375 transmitter in the radio compartment.

Sean engraved the switch and Eric Miller of Project Warbird fabricated the mounting plate.

Photo taken 22 December 2024.

Manual photo of the radio operator’s position aboard a B-17F.

The switch for the BC-375 transmitter is visible at the head of the table on the right. On B-17Gs, this switch was mounted to the table as an inlay.

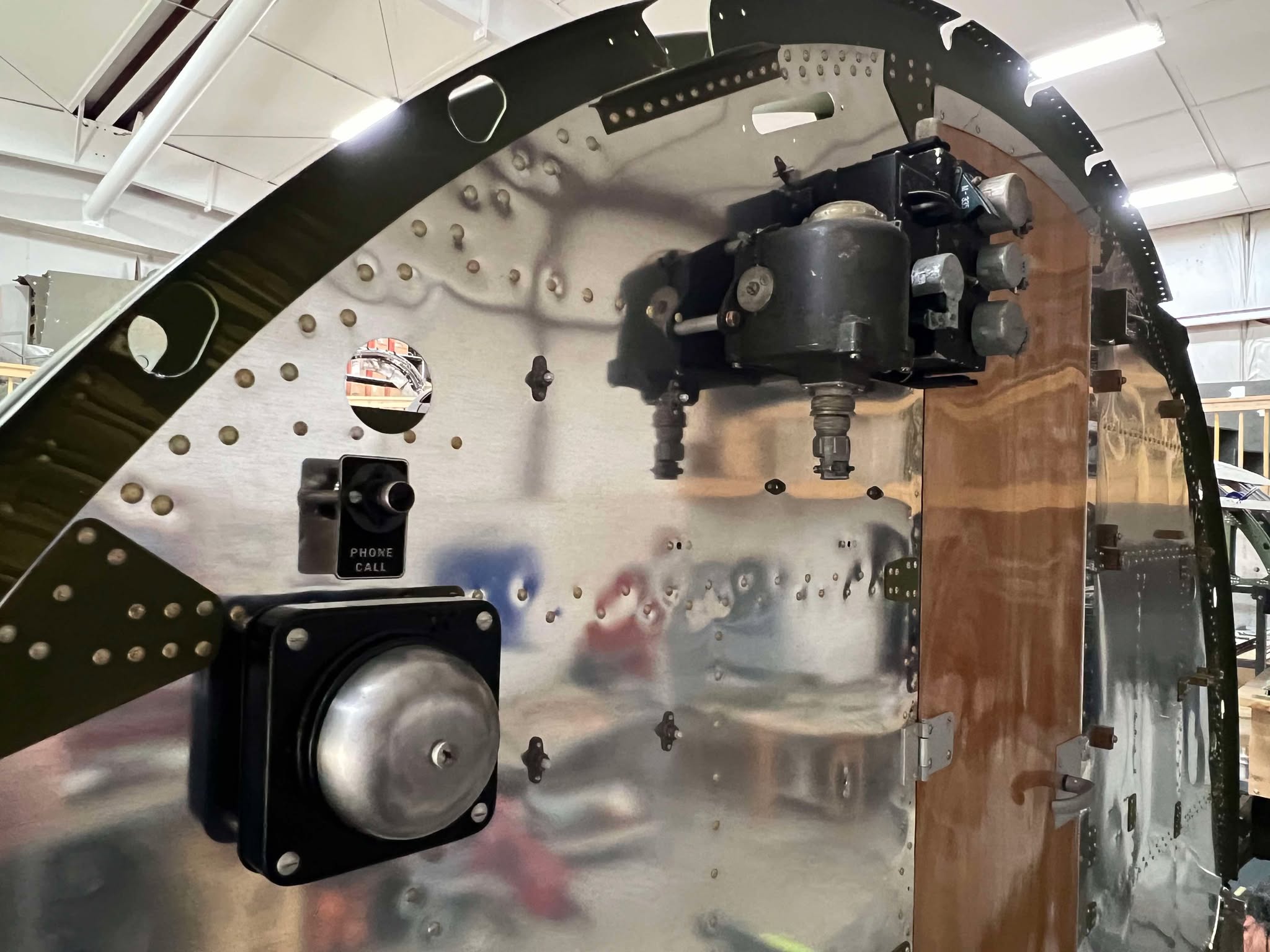

Progress shot showing Sta. 5 of Lucky Thirteen.

The call light and bailout bell are closest to the camera, while the IFF switch and control box are closer to the door. Spacers hold these pieces off the aluminum in anticipation of future fabric and insulation.

The placard for the call light was engraved by Sean Berry.

The power plug for the IFF and the ash tray have not yet been mounted. The latter still requires fabrication of its box assembly.

Photo taken 4 December 2024.

If you enjoyed this article, please consider supporting our work on Lucky Thirteen.

The Hangar Thirteen Foundation is a 501c3 nonprofit based in Asheville, North Carolina. We have no wealthy benefactor but are nevertheless uncompromising in our dedication to accuracy. Contributions toward the project are tax deductible and you can guarantee that fruits of your involvement will be seen here online. Financial donations help more than you can imagine, but for those uncomfortable or unable, we try to be open about the parts we need as well. Should you have a part you would like to contribute, just contact us. If you wish to donate, you can do so via PayPal using the Donate link. Or, if you would like to avoid PayPal taking its fee, you can send a check to Hangar Thirteen. Because we will soon be changing locations, we recommend my home address at:

Gerad Allen Blume

442 Old Chalk Bed Road

Batesburg, SC 29006

Everything we have accomplished thus far has been due to the support of those who believe in us. To those who have contributed before, we cannot thank you enough for the support you have given us. We hope we do you proud as we continue our efforts to properly honor the past.

Keep the show on the road!